Have you ever struggled with welding titanium? Do you want to give it a try? If so, we can help.

We’ll show you a simple method and tell you everything you need to know, step-by-step. So, please follow along.

We’ll show you a simple method and tell you everything you need to know, step-by-step. So, please follow along.

Let’s get started!

Can you weld titanium to steel?

Contents

Titanium and stainless are both strong, corrosion-resistant metals.

It is possible to weld the two together to make a durable, strong piece of equipment. There are certain considerations to take into account when welding titanium.

The first is the thread of the gas to be fused. The welder must match the classification of the titanium to that of the steel.

Otherwise, the weld may fail.

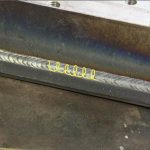

The other consideration is the quality of the weld. The weld should be smooth and fluid.

You may make a clean weld by increasing the welding current; however, the more current you use, the higher the heat input and hotter the weld is, which will hurt the titanium. Heat input is also related to the type of weld puddle.

To prevent fusion, the weld puddle needs to be kept cool. The two metals must reach the proper temperature for the weld puddle to melt and fuse together.

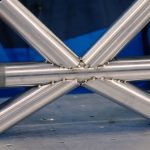

Aluminum also presents a problem for titanium weldments; however, it can be worked around by using aluminum filler material, such as TIG welding.

Titanium welds must withstand high stress from high heat, so that a heat-shield is necessary for welding aluminum car frames.

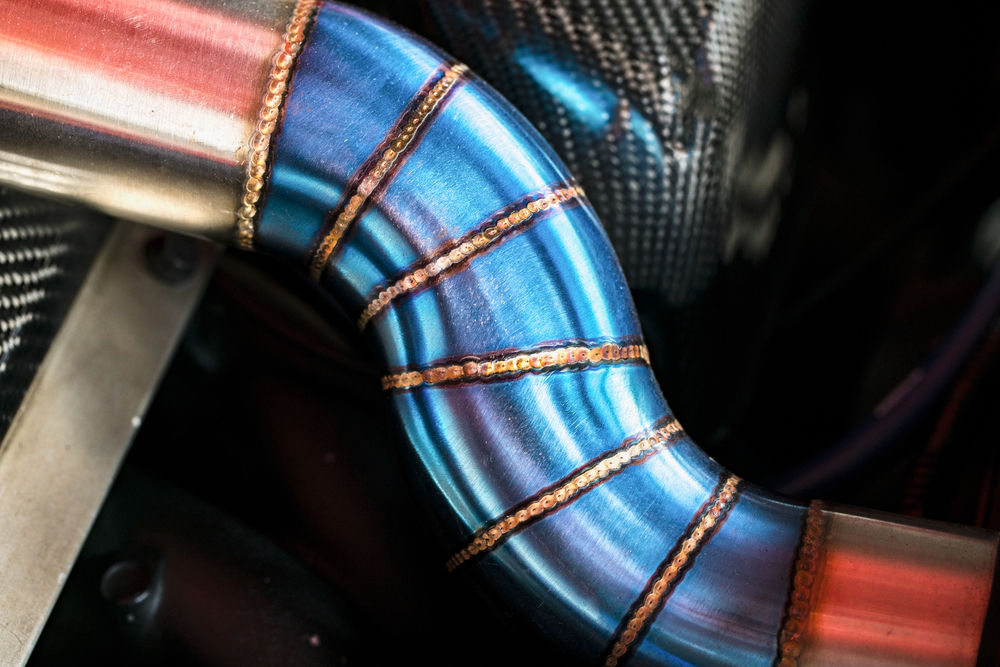

999 percent pure Argon gas , mixed with argon and helium, is used to shield the weld from oxygen, which in turn prevents a titanium weld from bubbling.

There is a special process for using TIG welding to fuse a titanium and steel bond. Titanium is more difficult to weld than steel, and requires a special type of TIG welding known as the submerged arc process.

Can you Weld on Titanium?

Titanium is as easy to weld as steel and stainless steel, although the electrode chosen and certain other details require careful attention.

Titanium may be fabricated into practically any shape.

Before you begin welding, make sure to wear gloves to protect your skin and to prevent any reactions.

Make sure that the torch is pointed down and that there are no flammable materials nearby. Once all the precautions have been taken, continue welding until the workpiece is thick enough.

While welding titanium, use a lower speed, longer arc. When welding, wear protective goggles and gloves to minimize the risk of reactions.

Before you start welding, make sure the titanium is cleaned of grease, oil, or paint.

You can guarantee a ductile and lasting weld using flux-cored wire and a flux-cored filler rod. Titanium welds may be oxyacetylene bonded or submerged arc welded.

What metal can you weld to titanium?

According to professional literature, titanium may welded to steel using explosives.

Copper and tantalum or vanadium interlayers may be deposited by spray coating the steel and the titanium.

Steel anvils are usually used to help form strong welds. Some professional welders use heat input in the weld, such as plasma arc welding, welding with an argon arc, or electron beam welding.

Plasma arc welding is a gas-tungsten arc welding technique that uses a plasma generator, or gun, to weld metal.

Argon arc welding, or TIG welding, in a vacuum chamber, is commonly used for titanium welding.

Compared to other metals, titanium requires an extremely low welding temperature in order to be welded.

Therefore, metallic filler metals such as stainless steel and cast iron are used extensively in titanium welding.

Welding titanium to steel is also possible. Regardless, all materials should be preheated prior to welding.

All metals should be held at a specific temperature in order to prevent them from warping.

Can you forge weld titanium and steel?

Yes, however you’d need to utilize an interlayer of niobium prior to welding. This would add the necessary strength to the weld.

Can you braze titanium to steel?

Ti has been brazed to stainless steel at a temperature between 798°C to 839°C.

Non Braze Welding Alloys (NBWAs) are important because they reduce welding heat input, which improves joint strength, reduces oxide stress cracking, and enhances welding quality.

In the late 1930s, Charles J.

Boyer developed a method for joining titanium to steel called vacuum brazing. This process of joining and welding has been around for over 90 years and is still in use today.

At temperatures between 854°C and 899°C, the alloy bonds to the surface of the metal while providing enough resistance to liquefy and flow out. Metals provide a very large surface area for contact between the alloy and the metal.

The surface to be joined must be clean and free of contaminants, usually welded and all oxide layers must be removed.

Titanium has a high melting point of 3,432°C, which gives it more melting temperature as compared to steel.

Using vacuum brazing to join titanium to steel structures results in quicker and easier brazing.

Temperatures for brazing are reached in cycles, so that heat cycles are applied.

Heating steel in alternating cycles to high temperatures helps create passive intergranular pores in the steel, which open up the steel up to alloying. The brazing process can be applied to nickel and other alloys.

Is titanium difficult to weld?

Titanium is also less difficult to weld than other exotic metals such as tantalum, molybdenum, tungsten, and molybdenum disulfide.

Despite the measures that must be taken, an increasing number of fabricators are welding titanium; in some cases, a fabricator may have to use a filler of some sort to guarantee the quality of the weld.

Do you weld titanium on AC or DC?

Because titanium is commonly welded using direct current (DC) rather than arc welding technology, it is preferred by most fabricators.

Can you MIG Weld Titanium?

The answer is yes, and it’s easy to MIG weld titanium. Since the melting point of titanium is only 2175°F, the weld deposit won’t burn through as easily; however, your MIG welder will require more power to complete the weld.

Even though most welders prefer tIG, you can MIG weld titanium.

Because titanium may burn through the plate, MIG welding is only recommended for thicker plates more than 3mm. However, despite its thickness, titanium is very ductile, so excessive heat flow is not an issue.

Because titanium has a high danger of burning through, TIG welding is not recommended when welding titanium.

Welding titanium requires a special skill. Once you pass the weld initiation phase, the puddle will quickly burn through the plate.

To prevent the puddle from burning through, you must cool the weld pool down quickly.