Are you a welding enthusiast who’s always on the hunt for affordable scrap metal to hone your skills?

Or maybe you’re a seasoned welder looking for new sources of materials for your next project? Whatever the case may be, finding scrap metal can seem like an overwhelming task if you don’t know where to look.

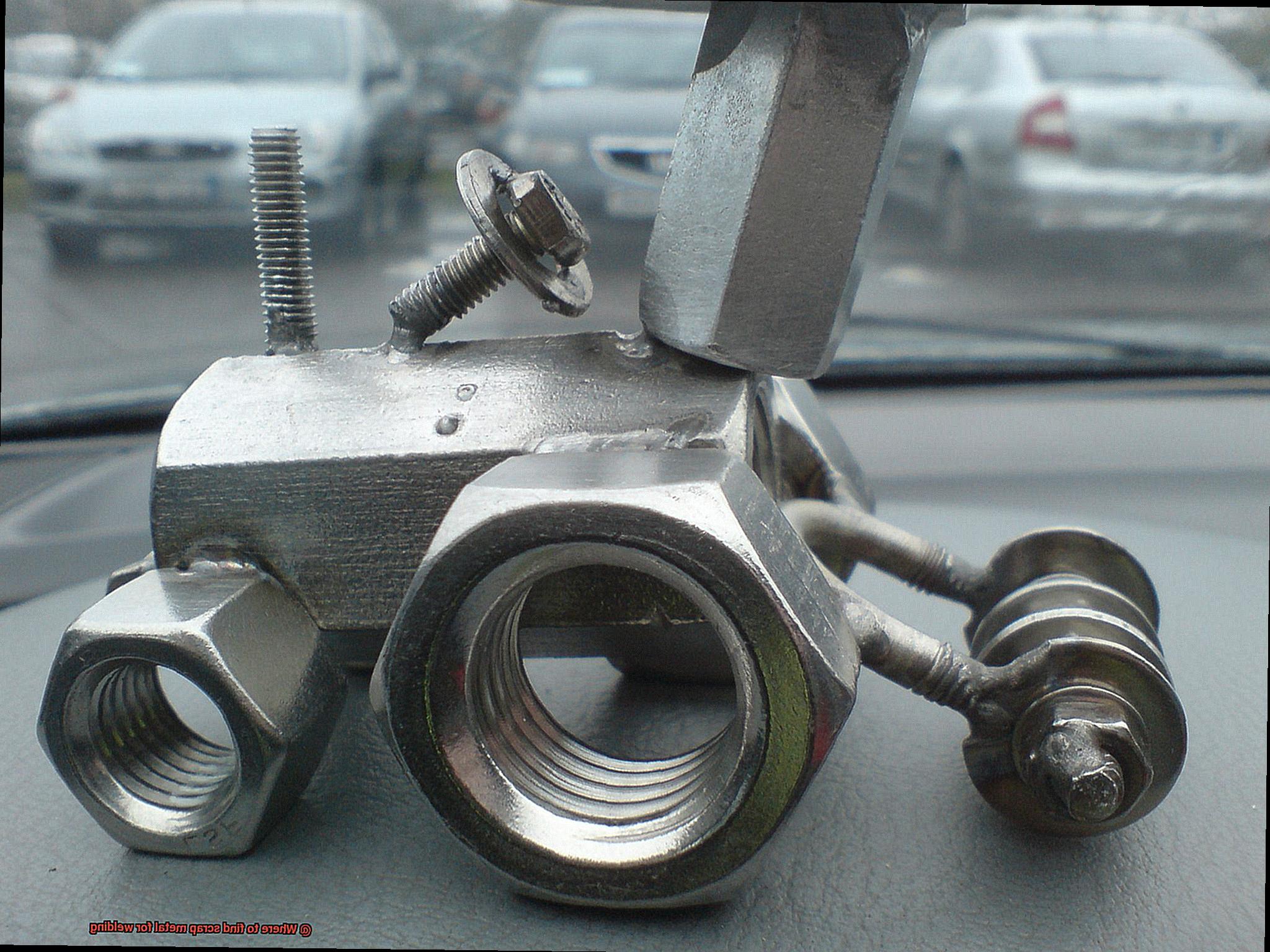

But fear not, as there are plenty of sources of scrap metal all around us. You just need to know where to find them.

From scrapyards and construction sites to junkyards and even your own backyard, there are endless possibilities waiting to be discovered. However, before embarking on your scavenger hunt, it’s crucial to do your research first.

In this blog post, we’ll explore the top places to find scrap metal for welding. We’ll also delve into the pros and cons of each source and provide tips on how to negotiate the best deals.

But that’s not all. We’ll also cover safety considerations when handling scrap metal and guide you through how to properly prepare it for welding.

Local Scrap Yards

Contents

Local scrap yards can be a treasure trove of various types of metals, including steel, aluminum, copper, and bronze.

Some scrap yards even specialize in specific metals, so it’s worth checking out different locations to find the perfect material for your welding project. Finding local scrap yards is easy – simply search online or check the Yellow Pages.

Many scrap yards also have websites that provide important information about their inventory, prices, and hours of operation. However, when visiting a scrap yard, make sure to wear gloves and sturdy footwear as the area can be hazardous.

Once you arrive at the yard, take a stroll around and inspect the different piles of metal carefully. You might even want to ask the friendly staff if they have any specific types of metal you’re looking for.

And if you plan on buying a large quantity of metal, don’t be afraid to negotiate for a better price. But it’s not just about buying scrap metal – you can also recycle your own scrap metal for some extra cash.

Many scrap yards will pay for certain types of metal based on weight and current market prices. It’s an excellent way to get rid of unwanted metal while making some money in the process.

However, it’s important to keep in mind that not all metals are created equal in terms of welding techniques and equipment required. For instance, aluminum and stainless steel require specialized welding techniques and equipment.

Therefore, make sure to identify different types of metals correctly and inspect them thoroughly for rust or other imperfections that could impact the quality of your weld. In conclusion, local scrap yards are an affordable and convenient option for finding scrap metal for your welding projects.

Construction Sites

You know that searching for high-quality scrap metal can be challenging.

Construction sites can be a thrilling source of materials for your welding projects. However, it’s crucial to keep in mind that accessing a construction site without permission is not only illegal but also hazardous.

Before you start rummaging through scrap piles, it’s highly recommended to contact the construction company or site manager to inquire about any available materials. If the construction site has already finished its project, there may be leftover materials that they are willing to sell or give away.

But obtaining permission is only the first step to ensure your safety. Construction sites are often littered with hazardous materials and debris, so it’s essential to take extra precautions when accessing these areas.

Wear protective clothing, such as hard hats and steel-toed boots, and always be aware of your surroundings. Moreover, some construction companies may have established relationships with metal recycling companies.

These companies may provide scrap metal at a cheaper price than traditional metal suppliers since their primary focus is recycling rather than selling the material for profit. Keep in mind that not all metals are alike and require different welding techniques and equipment.

So while construction sites can be an excellent resource for finding scrap metal, it’s critical to approach the situation with caution and obtain permission before accessing any materials.

Manufacturing Companies and Machine Shops

These businesses often have leftover materials from their production processes that they are willing to sell at a reduced price, making it a great option for those who need specific types of metal for their welding projects. To find these hidden gems, start with a quick online search or check with your local Chamber of Commerce to get a list of businesses in your area.

Many of these establishments have websites that list their available products and prices. You can explore the variety of scrap metals available, from small pieces to larger ones, and even unique shapes that can add character to your project.

But before you make a purchase, it’s important to consider the quality of the material. Make sure to inspect the metal before buying it to ensure it’s free from any defects or damage that could affect your welding work.

Additionally, be sure to ask about any safety precautions you should take when handling the metal, such as wearing protective gear or using specific tools. By purchasing scrap metal from manufacturing companies and machine shops, you can save money while still getting high-quality materials.

Plus, you’re contributing to sustainable practices by repurposing materials that would otherwise go to waste. So why not give it a try?

Online Marketplaces

These platforms, including eBay, Amazon, Craigslist, and Facebook Marketplace, offer a convenient and cost-effective way to find the materials you need. One of the major perks of using online marketplaces is the ability to search for specific types of scrap metal based on your needs.

With filters, you can narrow down the results and find exactly what you’re looking for. You may even stumble upon unique shapes and sizes that add character to your projects.

Not only can you buy scrap metal on these platforms, but you can also sell your own unwanted materials. It’s a win-win situation: you make extra cash and help others find materials for their projects.

However, with all great deals come potential pitfalls. Be sure to exercise caution when making purchases.

The quality and condition of the scrap metal may vary, so thoroughly inspect the item before buying it. Also, double-check that the quality meets necessary requirements for your welding project.

Identifying Different Types of Metals

Before you start welding, it’s essential to identify the type of metal you will be working with since different metals require different welding techniques and equipment.

So, let’s dive into the methods for identifying different types of metals.

Firstly, let’s talk about the magnet test.

It’s the easiest way to identify ferrous metals like steel and iron. If a magnet sticks to the metal, then it is a ferrous metal.

This test is super simple and can save you a lot of time and effort. If your metal doesn’t attract magnets, then it’s time for the spark test.

It’s like a fireworks show for metal enthusiasts. This test can help identify non-ferrous metals such as aluminum, copper, and brass.

All you have to do is grind the metal against a grinding wheel and observe the sparks that fly off. Each metal produces a unique color and shape of spark that can help you identify the metal.

Some metals have distinct colors that can help you identify them as well. Copper has a beautiful reddish-brown color, while brass has a warm yellowish-gold color.

Keep this in mind when identifying your metals. The weight test is another useful method for identifying metals.

Just pick up the metal and feel its weight. Aluminum is much lighter than steel, so this method can help you tell the difference between them.

Lastly, we have the acid test. This test is only for professionals who have experience with handling acids and should not be attempted by beginners.

The acid test can help determine if a metal is gold or silver. In conclusion, identifying different types of metals is crucial for successful welding projects.

By using these methods – magnet test, spark test, color test, weight test, and acid test – you’ll be able to easily identify the type of metal you’re working with and choose the appropriate welding techniques and equipment needed for your project.

Inspecting Metal for Rust, Corrosion, and Imperfections

Before you start any welding project, it’s crucial to inspect the metal thoroughly for rust, corrosion, and imperfections.

Just like building a house on a foundation made of sand, welding on weak metal can lead to disastrous results. Rust and corrosion are like termites slowly eating away at the metal’s integrity, weakening it and making it prone to breaking or cracking under pressure.

Discoloration, pitting, or flaking on the surface are all signs that the metal has been exposed to moisture and is starting to degrade.

It’s vital to remove all signs of rust and corrosion before welding to avoid any issues with the weld’s strength.

Imperfections such as dents or holes can create weak spots in the metal, affecting the overall quality of the weld. It’s like trying to build a house with a hole in the roof – it just won’t work.

Identifying these imperfections before welding is critical.

One way to do this is by shining a flashlight through the metal to reveal any holes or cracks that may be present.

Another method is by using a dye penetrant test, which involves applying a dye that will seep into any cracks or holes, making them visible.

By taking the time to inspect your metal for rust, corrosion, and imperfections, you’re ensuring that your welding project will be successful and long-lasting.

CL3O1nsbwx8″ >

Conclusion

In conclusion, don’t let the search for scrap metal for your welding projects intimidate you.

There are plenty of sources available, including scrapyards, construction sites, manufacturing companies, and online marketplaces. Of course, it’s essential to prioritize safety by researching and taking precautions before embarking on your scavenger hunt.

Local scrapyards offer a convenient and affordable option for finding various metals. Meanwhile, construction sites can be an exciting source of materials for your welding projects.

Manufacturing companies and machine shops are also great options as they often have leftover materials from production processes at reduced prices. Online marketplaces provide the convenience of searching for specific types of scrap metal based on your needs.

However, exercise caution when making purchases as the quality and condition may vary. Before starting any welding project, identify the type of metal you’ll be working with since different metals require different welding techniques and equipment.

By following these tips, you can find high-quality materials at a fraction of the cost while contributing to sustainable practices by repurposing materials that would otherwise go to waste.