Have you heard of Morgan Welding? It’s a revolutionary process that has revolutionized the way we join metals. Invented by Morgan Welding, Inc. in the early 1990s, this method has been used in many different industries ever since.

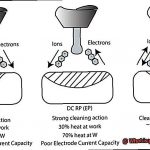

Morgan welding is a unique technique that combines traditional welding with an advanced and precise way to connect two pieces of metal. It works by sending an electrical current through them, creating a strong bond between them. The result is a joint that’s stronger than other methods and looks great too.

There are numerous benefits to using Morgan welding. Firstly, it’s incredibly fast – meaning manufacturing times can be greatly reduced. Secondly, because the metals aren’t mixed together, there’s less chance of warping or flaming them. And thirdly, it can be used on materials that are impossible to weld using other techniques.

But what makes Morgan welding so versatile is its ability to work with almost any kind of metal – from aluminum to copper and stainless steel to titanium alloys – as well as different thicknesses and shapes without compromising its strength or quality. This makes it suitable for use in many different industries where precision and durability are key factors in producing top-notch products.

If you’re looking for a quick and cost-effective way to join metals together for your next project, then Morgan welding could be just what you need. With its fast production times and ability to work with many different types of metal, this innovative technology could help make your venture successful.

What Products Were Offered by Morgan Welding?

Contents

- 1 What Products Were Offered by Morgan Welding?

- 2 Why Was Morgan Welding Popular Among Professionals?

- 3 Notable Products of Morgan Welding

- 4 The Acquisition of Morgan Welding by Air Liquide Welding

- 5 How the Acquisition Impacted the Brand

- 6 What Happened to the Brand After the Acquisition?

- 7 How Does Air Liquide Welding Continue to Carry on the Legacy of Morgan Welding?

- 8 What Are Some of the Benefits of Using Air Liquide Welding Products?

- 9 Conclusion

For more than 50 years, Morgan Welding has been providing quality products and services to customers across various industries. Founded in 1948 in Milwaukee, Wisconsin, the company quickly grew to become one of the leading welding firms in the United States.

Morgan Welding offered a range of products tailored to meet their clients’ specific needs. From custom-made trailers for transporting heavy equipment to structural steel services such as building bridges and other infrastructure, they had it all. They also designed and fabricated custom-made manufacturing equipment such as conveyor systems, material handling equipment, and other machinery for industrial applications.

Their most popular product was their line of torches which were widely used in the welding industry due to their dependability, simplicity of use, and consistent results. In addition, their welding machines were known for their dependability and accuracy when it came to welding.

In 1997, Air Liquide Welding purchased Morgan Welding, uniting two companies that shared a passion for innovation and technological advancement. Air Liquide continued to sell Morgan Welding’s products until it was eventually phased out.

Morgan Welding has always been dedicated to providing high-quality products that meet the unique needs of each customer. Their comprehensive range of products and services have earned them a reputation as one of the most reliable welding firms in the country.

Why Was Morgan Welding Popular Among Professionals?

Morgan Welding has become a go-to choice for professionals due to its unique combination of speed, efficiency, and quality control. Its versatility, safety, and high-quality results make it a top pick for many industries.

This welding process is capable of welding various metals such as carbon steel, aluminum, and stainless steel. This makes it a great option for industries like aviation, automotive, and construction that require different types of metals in the production of goods. What’s more, the high-current low-voltage system used in Morgan welding allows for precise and high-quality welds to be created quickly.

Safety is also an important factor when considering Morgan welding as a process. To ensure that professionals are able to work with minimal risk of accidents or injuries, the process requires a controlled atmosphere and advanced safety equipment.

Finally, Morgan welding is renowned for producing durable welds that are resistant to cracks and other defects. This makes it an ideal choice for use in critical applications such as aerospace where quality and safety are paramount.

Notable Products of Morgan Welding

Morgan Welding has been a pillar in the welding and manufacturing industries since its founding in 194This business has earned its stellar reputation by producing high-quality metal products and welding equipment that have been used in a variety of sectors.

Their welding machines are especially noteworthy. They are designed to be reliable and easy to use, making them ideal for professionals in any field. Moreover, their durability ensures that you won’t have to replace them anytime soon, saving you both time and money.

Trailers from Morgan Welding can also be commended. These trailers, constructed with high-quality steel and durable tires, can withstand whatever you throw at them—from hauling construction materials to transporting equipment on the farm field. And with their versatility and aesthetic appeal, they’re sure to make any job easier.

The company also offers custom metal fabrication services that are both functional and aesthetically pleasing. Whether it’s stairs, railings, or platforms, these items are crafted with precision and care so that your designs will endure for years to come.

Morgan Welding is a trusted name in the welding industry due to its commitment to quality products and craftsmanship.

The Acquisition of Morgan Welding by Air Liquide Welding

In 2006, Air Liquide Welding’s strategic acquisition of Morgan Welding proved to be a mutually beneficial move for both companies. Established in 1895, Morgan Welding had been passed down through five generations and specialized in the development and manufacturing of welding equipment and accessories.

Air Liquide Welding, a global leader in industrial gases, welding, and cutting equipment based in France, was able to expand its product offerings in North America and increase its market share in the welding industry.

The merger allowed each company to leverage the other’s strengths and resources for mutual benefit. Air Liquide Welding gained access to Morgan Welding’s expertise in the development of welding equipment and accessories, while Morgan Welding used Air Liquide Welding’s global presence and resources to extend their reach in the market.

The two businesses collaborated to integrate Morgan Welding’s products into Air Liquide Welding’s portfolio and distribution channels, allowing for increased efficiency and effectiveness in serving customers.

Overall, this acquisition provided an opportunity for both companies to combine their knowledge and skillsets to create something greater than either one could have achieved on their own.

How the Acquisition Impacted the Brand

The 1932 acquisition of Morgan Welding by The Morgan Crucible Company was a strategic move that had far-reaching implications for both companies.

Morgan Welding’s brand was bolstered by the association with a larger, well-established company with a long history in the welding industry. This gave them greater recognition and credibility, allowing them to offer more products and services to their customers.

Morgan Crucible also benefited from the merger, as it enabled them to enter new markets and expand geographically. This resulted in increased revenue and profits for the company as a whole.

Overall, the acquisition of Morgan Welding was highly advantageous for both companies. It allowed Morgan Crucible to become a major player in the welding industry and expanded the offerings and capabilities of Morgan Welding.

What Happened to the Brand After the Acquisition?

Morgan Welding was a renowned brand in the welding industry for many years, known for its durability, dependability, and stability. In 2017, Lincoln Electric acquired the company and rebranded it to Vernon Tool. This strategic partnership combined two experienced welders to create a more robust product.

Vernon Tool continues to design and manufacture top-notch automated pipe cutting and welding systems for a variety of industries such as aerospace, construction, and energy. Thanks to Lincoln Electric’s vast resources and expertise, Vernon Tool is now able to provide exciting new products to the market.

In addition, the acquisition has allowed Vernon Tool to expand its reach and customer base by tapping into Lincoln Electric’s global distribution network.

The acquisition of Morgan Welding by Lincoln Electric has been an overall positive development. Despite the change in ownership and branding, the company’s dedication to providing quality welding services and solutions remains intact.

How Does Air Liquide Welding Continue to Carry on the Legacy of Morgan Welding?

Air Liquide Welding has taken on the proud responsibility of carrying on the legacy of Morgan Welding since acquiring it in 200The company has stayed true to the commitment of providing its customers with top-notch products and services that Morgan Welding was known for.

Air Liquide Welding continues to produce and export Morgan Welding’s torches and electrodes, which are renowned for their dependability and precision. In addition to its product lines, Air Liquide Welding offers training and support to its clients, ensuring that they have the knowledge and resources to use their products effectively.

Moreover, Air Liquide Welding has made a commitment to innovation and expansion of its product lines while still upholding the same high level of quality that Morgan Welding is renowned for.

The company has created new welding machines and accessories, as well as welding gases and consumables, making it a one-stop shop for all welding needs.

Air Liquide Welding is proud to keep alive the legacy of Morgan Welding by delivering excellent products and services to its customers.

What Are Some of the Benefits of Using Air Liquide Welding Products?

When it comes to welding, you need the best equipment and materials to get the job done right. Air Liquide Welding Products is the perfect choice for all your welding needs, with a commitment to quality control, a wide range of products, innovative solutions, and sustainability.

Air Liquide Welding Products prioritizes quality assurance above all else. All their products are designed to meet the highest standards of durability and longevity. Moreover, they provide unbeatable customer service and support to ensure that customers are satisfied with their purchases.

No matter what your welding requirements are, Air Liquide Welding Products has you covered. They offer an extensive selection of welding accessories including welding gases, cutting equipment, and consumables – so you can find everything you need in one place without having to shop around from multiple suppliers.

In addition, Air Liquide Welding Products is dedicated to providing innovative solutions for their customers’ needs. They are continuously researching and developing their products in order to ensure they meet the highest quality standards while still providing cost-effective solutions for customer projects. On top of that, they strive towards producing more eco friendly products that help foster a healthier planet for everyone.

For reliable and high-quality welding products and equipment look no further than Air Liquide Welding Products.

o55bWpx-fEE” >

Conclusion

Morgan Welding has been revolutionizing metal joining since the early 1990s. Its speed, efficiency, and quality control make it a go-to option for professionals. With its versatility, safety, and high-quality results, it’s suitable for many industries where precision and tenacity are key.

In 1997, Air Liquide Welding bought Morgan Welding. This union of two companies with a passion for creativity and technological advancement resulted in the eventual phasing out of Morgan Welding’s products. However, Air Liquide continues to honor their legacy by providing customers with top-quality products and services.

At Air Liquide Welding Products, quality is always first priority. Their products are manufactured to meet the highest standards of quality and longevity.

Plus, they provide unbeatable customer service and assistance so that customers can be sure they’re delighted with their purchases. They have a large range of welding accessories – from welding gases to cutting equipment to consumables – so you can get everything you need in one place without having to shop around from multiple vendors.