What pressure should argon have for MIG welding?

Are you wondering what pressure argon needs for MIG welding?

It’s an important question to answer if you want to achieve the best results. I’m here to help.

I’ll explain why argon pressure is so critical, as well as how to adjust your settings for various materials. Plus, I’ll provide some tips and tricks for setting up your machine properly for consistent results.

You’ll learn why welding with argon is essential and how it can help you avoid common mistakes like porosity or poor penetration. I’ll also show you how to get the most out of your welds every time.

You’ll find out everything you need to know about gas pressure and flow rate, and be able to create perfect welds each and every time.

Factors to Consider When Setting Argon Pressure for MIG Welding

Contents

- 1 Factors to Consider When Setting Argon Pressure for MIG Welding

- 2 The Ideal Pressure Range for Argon Gas Used in MIG Welding

- 3 How to Determine the Correct Pressure for Your Specific Welding Application

- 4 Tips to Ensure You Have a Properly Filled Tank of Argon

- 5 Safety Precautions When Setting Argon Pressure for MIG Welder

- 6 Benefits of Using the Correct Argon Pressure for MIG Welding

- 7 Common Mistakes Made When Setting Argon Pressure

- 8 Conclusion

For MIG welding, setting the right argon pressure is essential for producing strong and durable welds.

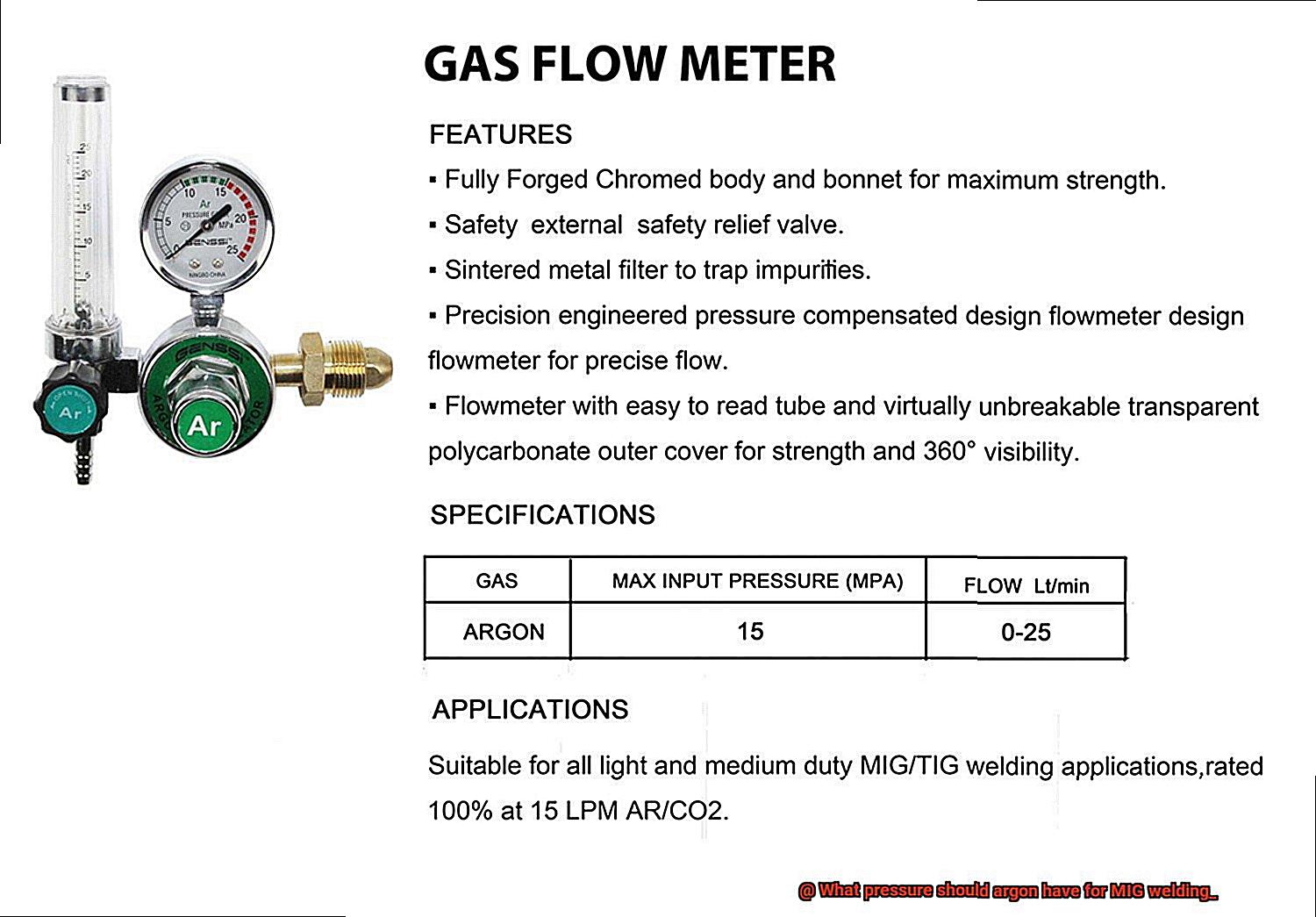

Argon gas is used to shield the weld pool from contamination and oxidation, but it can be tricky to determine the optimal pressure. Generally, a range of 15-20 cubic feet per hour is recommended, though this may vary depending on factors such as metal thickness, joint type, and nozzle size.

It’s important to check your welding equipment manufacturer’s instructions for guidance on the ideal pressure for your application. Additionally, make sure that your argon tank is properly inflated before beginning any welding projects; a full tank should have a pressure range between 2000-2200 psi (pounds per square inch).

Both the regulator and flow meter must be set correctly in order to ensure that you are using the appropriate amount of argon gas.

The Ideal Pressure Range for Argon Gas Used in MIG Welding

MIG welding is an incredibly effective and versatile welding process, but getting the settings just right can be a challenge.

One of the most important aspects of producing quality welds is to ensure the argon gas pressure is set correctly. In this article, we’ll explore the ideal pressure range for argon gas used in MIG welding, as well as some tips on how to get it spot-on.

Generally speaking, the recommended pressure range for argon gas in MIG welding lies between 20 and 25 cubic feet per hour (cfh). However, this range can vary depending on certain factors.

For instance, if you’re using a smaller tank (e.g., 20 cubic feet), you may need to use more pressure to maintain a consistent flow rate. Conversely, if you’re using a larger tank, you may need to use less pressure to achieve the same result.

Additionally, it’s essential to keep your tank full throughout your welding project; if it’s running low, the pressure will drop and your welds won’t be as strong or consistent. Moreover, the specific MIG welder being used will also influence the ideal pressure range for argon gas.

Additionally, if you plan on using 100% argon gas in your MIG welding project, it’s important that all of the necessary adjustments are made correctly; seek advice from a professional or manufacturer if needed.

How to Determine the Correct Pressure for Your Specific Welding Application

Welding is like a science experiment: get the pressure of your argon gas wrong and you won’t get the desired results. That’s why it’s so important to determine the correct pressure for your specific welding application. Here’s how to do it.

First, consider several factors such as the type of material being welded, its thickness, the type of weld joint being used, and the size of your welding gun nozzle. The recommended gas flow rate for MIG welding with argon gas is typically between 20 and 30 cubic feet per hour (CFH), but this can vary depending on your specific application.

When it comes to pressure, most manufacturers suggest setting it between 15 and 25 psi (pounds per square inch). However, be sure to consult your welding machine’s manual or an expert before making any decisions. Too much pressure can cause turbulent gas flow and bad welds while too little can lead to porosity and weak welds.

It’s also important to check the pressure in your argon tank regularly. A full tank should have a pressure of around 2000 psi, but this will decrease as you use it so make sure you replace it when it falls below 500 psi.

Tips to Ensure You Have a Properly Filled Tank of Argon

Ensuring that your argon tank is properly filled is essential for successful MIG welding and a safe working environment. Here are five tips to guarantee that your tank is always full and ready to go.

Check the Pressure

Before beginning any welding job, make sure to check the pressure level of your argon tank with a pressure gauge. The ideal pressure for MIG welding with argon gas should be between 20-25 CFH (cubic feet per hour).

Weigh the Tank

Argon gas is sold by weight, not by volume, so it’s important to weigh the tank before and after use to ensure you’re getting the right amount of gas you paid for. A full argon gas tank should weigh approximately 150 pounds.

Adjust Gas Flow

Setting the flow rate between 20-25 CFH will help reduce overconsumption of gas and prevent oxidation while producing high-quality welds with minimal porosity.

Store Properly

Storing your argon tank correctly will help prevent contamination and ensure that it is filled to capacity. Keep it in a cool and dry location away from direct sunlight or heat sources, and make sure that it is upright when not in use.

Buy from Reputable Dealers

It is vital to source your argon gas from recognized welding suppliers who conduct vital quality checks and properly fill tanks before delivering them to customers. This ensures that you get quality gas that meets industry standards and avoids contamination for better welds.

Safety Precautions When Setting Argon Pressure for MIG Welder

When setting the argon pressure for MIG welding, safety should always be top of mind.

This is because argon gas is odorless, colorless, and tasteless, and can easily go unnoticed if leaked into the air. Thus, it’s important to take the necessary precautions to prevent any potential harm.

Start by making sure that the gas cylinder is in an upright position and secured with a chain or strap. Additionally, gauge the amount of gas remaining in the cylinder before using it to avoid running out mid-weld.

It’s also essential to adjust the argon pressure settings according to your welder’s user manual. Generally, a MIG welder requires a gas flow rate of between 20 and 25 cubic feet per hour (CFH) at a pressure of between 20 and 30 pounds per square inch (PSI).

J87Z4NRvTn0″ >

Benefits of Using the Correct Argon Pressure for MIG Welding

MIG welding is an art form that requires skill, precision, and the right equipment – and argon gas is a key component of this technique.

To ensure you get the most out of your argon gas, you must use the correct pressure. The ideal pressure for argon gas used in MIG welding is usually between 15 and 20 cubic feet per hour (CFH).

This range helps maintain a steady flow of gas while protecting the weld pool without wasting too much gas. But why is it so important to use the correct Argon pressure?

There are numerous benefits associated with using the appropriate Argon pressure for MIG welding. Firstly, it helps reduce oxidation and contamination during the welding process, resulting in a stronger, more durable weld.

Secondly, it enables you to control your welding speed and penetration depth for a more accurate and consistent weld quality. Finally, it reduces welding defects such as spatter, cracking, and incomplete fusion – saving both time and money in the process.

Check with your manufacturer’s instructions to determine which settings are best suited for your specific application or project.

Common Mistakes Made When Setting Argon Pressure

MIG welding is a delicate balancing act, and getting the argon pressure right is key to achieving the perfect weld.

However, many welders make common mistakes when setting the pressure of the argon tank. For starters, not consulting the manufacturer’s instructions for your specific welder model can lead to incorrect pressure settings.

Different materials and thicknesses require different pressures, so it is essential to adjust accordingly for optimal results. Ignoring this step can cause poor weld quality, porosity, and even penetration issues.

Not properly maintaining your regulator is another common error. Dirt and debris can accumulate in the regulator, resulting in malfunctioning and inaccurate pressure output.

Additionally, neglecting to purge gas lines before each use can also affect accuracy – don’t forget this step.

Conclusion

Getting the pressure of your argon gas right when MIG welding is essential for durable welds.

Generally, 20-25 CFH (cubic feet per hour) is recommended. However, this range can vary depending on the material type and thickness, weld joint type and size of the welding gun nozzle.

To ensure the correct pressure for your application, check your welding equipment manufacturer’s instructions. Also, before starting a job, make sure to inflate your argon tank to 2000-2200 psi (pounds per square inch).

And don’t forget to try out new settings and keep your tank topped up throughout any welding projects. Safety should also be top priority when working with argon gas.

Furthermore, always adhere to safety instructions issued by manufacturers or experts and adjust argon pressure settings according to your welder’s user manual.