One of the most common building materials used in welding is soapstone. In this blog post, we’ll explore the role of soapstone in welding.

We’ll discuss how it works, why it’s so important, and the unique properties that make it an ideal material for welding projects.

So if you’re looking for an introduction to welding and what makes it tick, keep reading to learn all about soapstone and its importance in welding.

How is Soapstone Formed?

Contents

- 1 How is Soapstone Formed?

- 2 What is a Soapstone Marker?

- 3 What Is Soapstone Used for in Welding

- 4 What are the Different Uses of Soapstone?

- 5 Are Soapstone Marks Easy to Erase?

- 6 What is Welders’ Soapstone Made of?

- 7 How Does Welders’ Soapstone Differ from other Types of Markers?

- 8 Advantages of Using Soapstone in Welding

- 9 Disadvantages of Using Soapstone in Welding

- 10 Conclusion

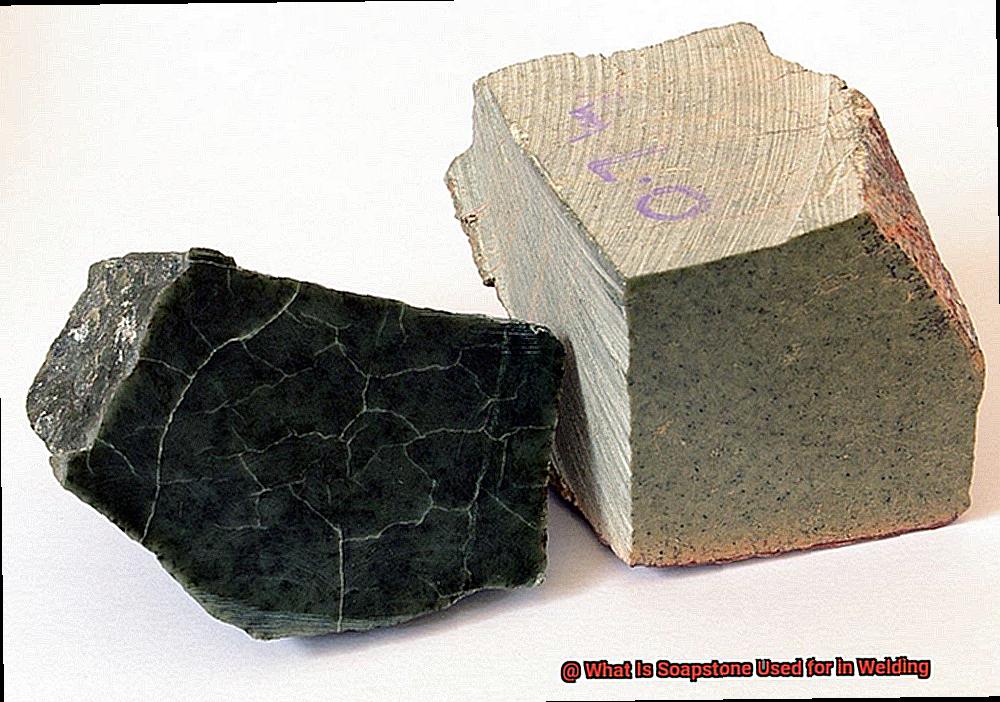

Soapstone is a truly remarkable metamorphic rock, formed when heat and pressure are applied to existing sedimentary rocks.

Its composition as the main talc gives it its distinctive properties; it’s highly resistant to heat and chemical erosion, as well as being non-porous.

Plus, soapstone comes in a range of colors, from white to gray and even yellow. When exposed to higher temperatures, the color of soapstone can change from white to gray or black.

For centuries, people have been drawn to soapstone for its tenacity and beauty. It has been used for a variety of applications, from countertops and sculptures to cookware and stoves.

What is a Soapstone Marker?

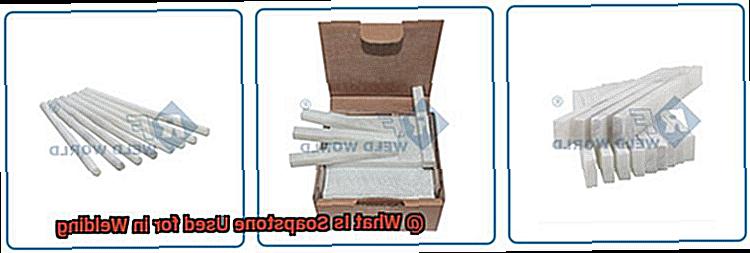

Are you looking for the perfect tool to make temporary marks on metal surfaces? Look no further than a soapstone marker! This soft, non-porous stone is composed of talc or magnesium silicate, making it heat- and corrosion-resistant.

Soapstone markers are incredibly versatile and can be used for a variety of welding purposes. Mark the location of welds, identify materials, and indicate the direction of welding—the possibilities are endless.

They can also be used to create patterns on metal surfaces or mark areas that need to be cut or ground away. Plus, they’re easy to shape into different sizes and shapes.

If you need to make temporary marks on metal surfaces, then a soapstone marker is your go-to tool.

What Is Soapstone Used for in Welding

Soapstone is a popular material used in welding. It is a soft, dense mineral composed of talc and other minerals, which makes it an ideal material for welding.

Soapstone has been used for centuries in welding because of its low melting point and its ability to withstand high temperatures. It is also easy to shape and manipulate, making it an ideal material for welding.

Soapstone is often used in welding to create a smooth finish on the welded joint. The material can withstand high temperatures, so it can be used to create a strong bond between two pieces of metal.

It also helps to reduce the amount of heat that is generated during the welding process, which can help to reduce warping and other issues. Soapstone can also be used to fill gaps between two pieces of metal, resulting in a more secure connection.

Finally, soapstone is also used in welding because it is non-reactive and does not corrode easily. This makes it an ideal material for welding in corrosive environments, such as those found in marine or industrial applications.

Soapstone also does not require any special preparation or treatment before use, making it easy to use and cost-effective.

All in all, soapstone is an excellent material for welding and can provide a strong bond between two pieces of metal.

What are the Different Uses of Soapstone?

Soapstone is a remarkable and versatile material that can be used for a range of welding tasks. From marking metal with lines and shapes to areas for welding, cutting, and grinding, soapstone is the perfect material to have on hand when you’re welding.

It’s also great for creating templates for curved or angled welds as well as intricate patterns.

Not only that but it can also be used to mark areas that need to be heat treated or painted. And finally, soapstone can even be used as a flux when soldering or brazing.

Are Soapstone Marks Easy to Erase?

The answer is a resounding yes! Whether you’re using chalk, wax, paint, or ink, these marks are generally easy to remove. All you need is a damp cloth and you can easily wipe away softer materials. If the mark is made of a more permanent material such as paint or ink, then you may need a degreaser or solvent to get rid of it completely.

However, it’s important to note that soapstone marks may not always disappear completely so use caution when marking surfaces with them.

What is Welders’ Soapstone Made of?

Welders’ soapstone is a must-have tool for any welder! This remarkable product is made from a combination of minerals, including talc, magnesium, calcium, silicon, and iron.

The minerals are melted and ground into a fine powder that can be used to make marks on the metal. With an oxy-acetylene torch, the soapstone is pressed against the metal surface and heated.

The heat causes the soapstone to fuse with the metal surface, leaving a permanent mark that can be used for welding. It’s amazing to think that something so simple could be so essential in welding.

Welders’ soapstone is an incredible product with a unique origin story.

How Does Welders’ Soapstone Differ from other Types of Markers?

Welders need a reliable marking tool, and that’s where welders’ soapstone comes in. This unique marker is made from a combination of talc and clay, making it soft enough to mark on metals and easy to erase.

Not only that but it’s designed for high-temperature use, perfect for welding operations.

Plus, welders’ soapstone can be used to make both permanent and temporary marks on metal and other surfaces – an invaluable feature for any welder.

Advantages of Using Soapstone in Welding

Welding is an art form that requires precision and accuracy. Soapstone is one of the top materials to use when welding due to its non-toxic, non-flammable, and easy-to-handle properties.

Not only is it durable and able to withstand high temperatures without cracking or becoming brittle, but it also leaves precise markings on the surface of the material being welded.

Soapstone markers are a great choice for welders because they are waterproof, meaning they won’t be affected by moisture or water exposure. This ensures that your markings will last longer than other types of markers.

Plus, soapstone markers are inexpensive and widely available, making them an accessible option for any welder looking to document their projects quickly and efficiently.

So, soapstone is a safe and reliable material to use when welding.

It’s non-toxic, easy to handle, can withstand high temperatures, is waterproof, and is affordable and widely available.

Disadvantages of Using Soapstone in Welding

Welders often turn to soapstone as an easy and convenient way to mark metal.

But despite its convenience, soapstone comes with some drawbacks. Firstly, the markings are not permanent and can be easily erased or damaged.

On top of this, they can be difficult to spot on shiny surfaces and are prone to smudging and fading.

Furthermore, soapstone markers may contain dangerous chemicals, so it is essential to work in a well-ventilated area when using them.

Lastly, using soapstone in welding can be time-consuming as the markings need to be refreshed regularly.

Conclusion

Soapstone is an essential tool for welders, offering a range of advantages that make it the go-to material for marking metal surfaces. Its heat and corrosion resistance, non-toxic nature and high-temperature tolerance make it ideal for welding projects.

Plus, soapstone can even be used as a flux when soldering or brazing!

But there are some drawbacks to using soapstone in welding – including its lack of permanence and potential danger from hazardous chemicals.

All in all, soapstone is an invaluable resource for welders.