Do you know what holds your car’s body panels together? It’s called a pinch weld.

In this blog post, we’ll look at what a pinch weld is, why it’s important for keeping your car safe and looking great, and how to address any common challenges with pinch welds. Get ready to learn all about them!

What is a Pinch Weld?

Contents

- 1 What is a Pinch Weld?

- 2 How Do You Jack a Car with Pinch Welds?

- 3 Can You Put Jack Stands on Pinch Welds?

- 4 How Do You Restore Pinch Welds?

- 5 Can Pinch Welds Be Repaired?

- 6 How Do You Remove a Pinch Weld?

- 7 Benefits of Using Pinch Welds for Vehicle Repair

- 8 Common Mistakes to Avoid When Working with Pinch Welds

- 9 Conclusion

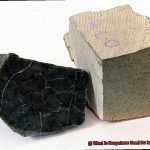

It’s an incredible process that joins two pieces of metal together with strength and durability. In the automotive industry, pinch welds are commonly used for car body repairs as they create a secure bond between the two pieces of metal.

The process involves using heat and pressure to melt the edges of the two pieces of metal together, resulting in a strong bond that can withstand extreme temperatures and impacts.

Pinch welds are also used in other industries such as aerospace and construction for their reliable strength and durability.

How Do You Jack a Car with Pinch Welds?

Pinch welds are the perfect solution. Pinch welds are metal seams on the underside of a vehicle that provide stability when lifting with a jack.

To use pinch welds, simply place your jack directly under the pinch weld and slowly lift until it reaches your desired height.

Once you’ve lifted your car, add extra stability and safety by placing jack stands on either side of the pinch weld.

Before getting underneath the car for any repairs or maintenance, make sure to check that your jack stands are properly secured.

Can You Put Jack Stands on Pinch Welds?

For any DIY car enthusiast, having the right tools and knowledge is essential. One of the most important tools for working on your vehicle is a jack stand. But, when it comes to using pinch welds as a support point, can you safely place your jack stand?

The short answer is no. Pinch welds are typically too thin and weak to handle the weight of a car, so they should not be used with jack stands.

If you must use pinch welds, make sure you have something strong, like a thick piece of metal or wood, between the jack stand and the pinch weld for extra support. Additionally, be careful not to damage the pinch weld while using it as a support point.

When it comes to using jack stands, safety should always come first.

Pinch welds may appear like an ideal spot for displaying your jack stands, but it isn’t safe or recommended. Make sure you choose a secure surface that won’t put your vehicle at risk.

For extra security and safety, try using a thick piece of metal or wood instead of pinch welds when placing your jack stand.

How Do You Restore Pinch Welds?

Whether you’re grinding, welding, or patching, there are several ways to bring your pinch welds back to life.

Grinding is the most popular method for restoring pinch welds. It involves removing rust and corrosion from the metal surface, making it look like new again. To get the job done right, you’ll need a grinder with a grinding wheel.

Welding is also an effective way of recovering pinch welds. It can be used to fill in any gaps or holes in the metal. If you don’t have experience with welding, however, it’s best to leave this job to a professional.

Patching is a less common approach but can still be used to fill in smaller holes or cracks in the pinch weld area. When patching, make sure you use the appropriate materials, such as epoxy putty or body filler.

No matter which method you choose, it’s important that all rust and corrosion are removed before attempting any repair work on the pinch welds. This will help prevent further damage from occurring. Additionally, make sure that you use the correct tools and equipment; improper tools may cause more harm than good!

Can Pinch Welds Be Repaired?

This type of repair requires precision and skill, but with the right tools and knowledge, you can get your car back in working order.

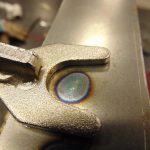

The process begins with grinding away the old weld, cleaning the area, and then welding in a new piece of metal. It’s important to use high-quality welding rods designed specifically for this kind of repair. The weld should be even and smooth, with no gaps or bumps.

After welding, the area should be sanded down to create a smooth surface before applying a primer coat for protection.

With patience and expertise, pinch welds can be restored, so you can get back on the road safely! Don’t let damaged pinch welds slow you down; take action today and get your car repaired!

How Do You Remove a Pinch Weld?

Removing pinch welds can be a tricky task, but with the right tools and techniques, it can be done quickly and safely.

Pneumatic chisels, grinding wheels, and cutting discs are all viable options for removing pinch welds from the table.

To protect the surrounding metal from damage, it is essential to use the right tool for the job.

When using a pneumatic chisel, short bursts should be used at an angle to ensure that the weld is broken without damaging the nearby metal.

Once broken, it can be carefully pried away from the surface with a flathead screwdriver or other suitable device.

Grinding wheels are also useful when removing pinch welds, but they must be used with caution to avoid damaging nearby metal. Start by grinding away at the edges of the weld until it is loose enough to pry away from its base.

Cutting discs are another option for removing pinch welds.

However, they should only be used on thicker sections of metal, as they can easily damage thinner sections.

When using a cutting disc, hold it at an angle and then slowly move it across the surface of the pinch weld until it has been cut through completely.

Once all of the pieces have been removed, any remaining debris should be cleared up with a wire brush or vacuum cleaner before re-welding or repairing any damaged areas.

Benefits of Using Pinch Welds for Vehicle Repair

Are you looking for a reliable and cost-effective way to repair your vehicle? If so, pinch welds are the perfect solution! Pinch welds are strong and durable, making them ideal for repairing cars and trucks. Plus, they require minimal effort for installation and can be used in a variety of applications, from frame repairs to bodywork.

Not only are pinch welds easy to install, but they are also incredibly cost-effective. They can be reused multiple times without needing any additional materials or tools beyond what is already available in most automotive shops.

This means that you can save money in the long run by using pinch welds instead of other repair methods.

Finally, using pinch welds can also help reduce the amount of time needed to complete a repair. Since they can be installed quickly and easily with minimal effort, you won’t have to wait around for hours while your car is being fixed.

Common Mistakes to Avoid When Working with Pinch Welds

Working with pinch welds can be tricky, but with the right know-how and safety equipment, you can ensure that your welds are strong and reliable. To make sure that your welds come out perfect, here are nine common mistakes to avoid when working with pinch welds.

First, always make sure to clean the pinch weld before welding.

This will guarantee that there is no dirt or debris present and will help create a secure connection between two pieces of metal. Additionally, it’s important to use the correct welding equipment for your project.

Different types of welding require different kinds of tools, so make sure you’ve got the right one!

Safety should also be a top priority when working with pinch welds.

Always wear protective gear, such as gloves and goggles, and keep the area well ventilated. Preheating the metal before welding is also essential, as it reduces warping and distortion.

Lastly, don’t forget to allow enough time for cooling after welding.

Conclusion

Pinch welds are an essential part of any car repair.

They provide strength and stability when two pieces of metal come together. From grinding to welding, there are several methods for patching pinch welds, but it’s still important to ensure the job is done safely and correctly.

With the right know-how and security equipment, you can trust your pinch welds will be strong and reliable for years to come.

Don’t let bad pinch welds slow you down; take action today and get your car fixed.