Are you a welding enthusiast on the hunt for a versatile welding rod that can handle a range of metals? Look no further than the 6011 welding rod. This powerhouse tool is a staple in many welders’ arsenals, thanks to its impressive adaptability and deep penetration capabilities.

But what exactly is 6011 welding rod used for? This heavy-duty rod is ideal for general purpose welding jobs, including repairs on pipes, structural steel, and heavy equipment. Additionally, it’s the go-to choice for welding in tight spaces or hard-to-reach areas where other rods may struggle to fit.

One of the most unique features of the 6011 welding rod is its ability to penetrate deeply into metals. This makes it an excellent option for thicker metals, as well as those that are dirty or rusty and difficult to clean beforehand. With this powerful tool at your disposal, you can tackle even the toughest welding projects with ease.

In this blog post, we’ll take a deeper dive into the world of the 6011 welding rod and explore its many uses and benefits. From its versatility to its superior penetrating capabilities, you’ll soon discover why this tool is an essential addition to any welder’s toolkit. So grab your mask and let’s get started – there’s no telling what amazing creations we can make together with this incredible tool.

What is 6011 Welding Rod?

Contents

This trusty electrode is renowned for its versatility, ease of use, and deep penetration capabilities. But what exactly is a 6011 welding rod, and what sets it apart?

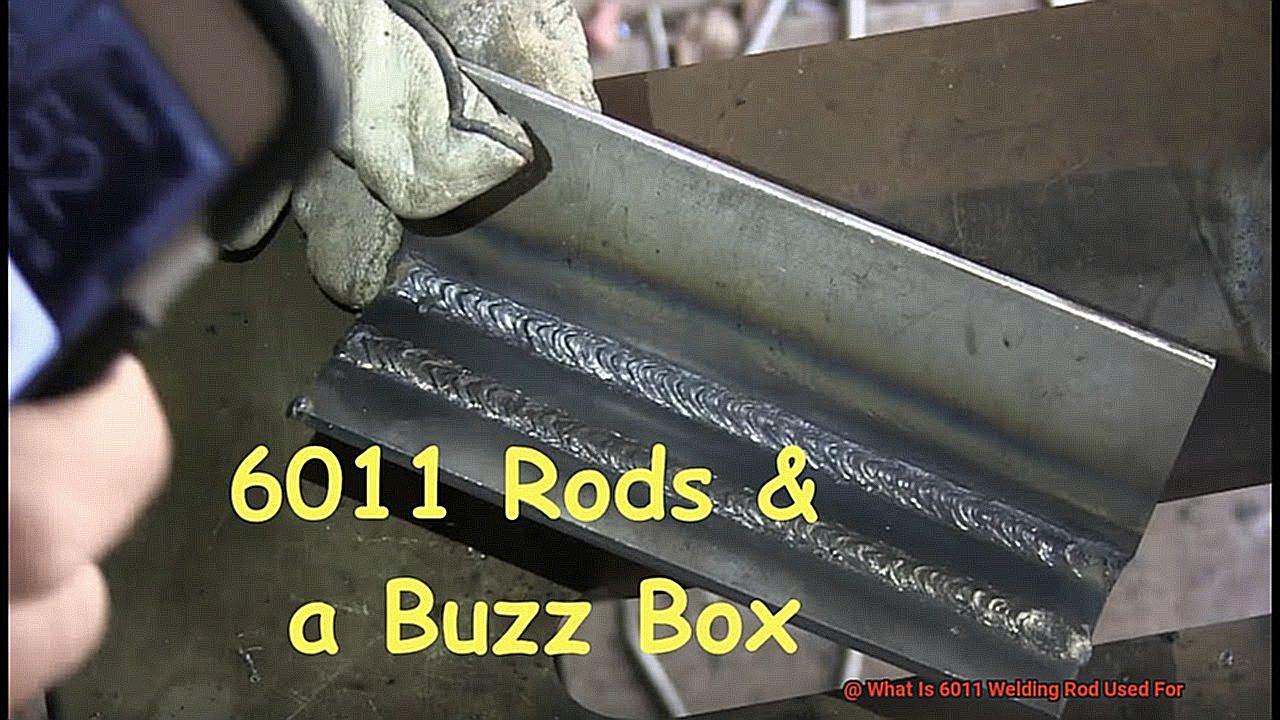

At its core, the 6011 welding rod is an all-position, cellulosic electrode made up of mild steel, cellulose, and potassium. Its unique composition gives it a quick solidification rate that allows for deep penetration into the base metal, earning it the nickname “fast-freeze” or “deep-penetration” rod.

One of the key advantages of using a 6011 welding rod is its ability to be used with both AC and DC currents. This makes it highly versatile and compatible with a wide range of welding machines. Additionally, its smooth, stable arc makes it easy to control, even for those new to welding.

Another benefit is that 6011 rods produce minimal slag, making them ideal for overhead welding or other situations where slag buildup could be an issue. This makes cleanup a breeze and helps expedite the welding process.

In terms of applications, the 6011 welding rod excels in welding mild steel, galvanized steel, and other low-alloy metals. It’s a popular choice in the construction industry for structural welding and repairs, as well as for welding pipes and pipelines. Its deep penetration capabilities make it perfect for thicker materials like plates and pipes.

It’s worth noting that there are two types of 6011 welding rods available: the E6011 and the E6010. The E6011 is designed for use with AC or DC positive polarity, while the E6010 is designed for use with DC negative polarity. The primary difference between them lies in their polarity requirements.

Overall, the 6011 welding rod is a reliable and versatile electrode that produces high-quality results.

What Are the Benefits of Using 6011 Welding Rod?

One of the biggest advantages of using 6011 welding rod is its versatility. It’s compatible with a variety of metals, including galvanized steel, carbon steel, and stainless steel. This means you won’t have to switch between different types of rods for different projects – saving you time and money.

But that’s not all. The 6011 welding rod is also incredibly easy to use. Whether you’re a seasoned pro or just starting out, this rod is simple to strike and maintain an arc with. And with a smooth and clean weld bead, it’s perfect for achieving a polished finish on your final product.

Another benefit of the 6011 welding rod is its ability to penetrate deep into metal. This makes it an excellent choice for welding thicker materials that require extra strength and durability. With this rod, you can trust that your weld will hold up under heavy loads and stress.

And here’s something else that sets the 6011 welding rod apart from the rest: it can be used in both AC and DC welding processes. This means it’s compatible with a wide range of welding machines, making it a versatile and convenient choice for any project.

What Types of Metals Can Be Welded With 6011 Welding Rod?

This all-purpose electrode is a go-to choice for welding in maintenance and repair applications thanks to its ease of use and adaptability.

The 6011 welding rod can be used to weld mild steel, galvanized steel, stainless steel, cast iron, and some non-ferrous metals like aluminum and copper. Keep in mind that the type of metal being welded will affect electrode performance, so it’s essential to choose the right electrode for the job. Thicker sections of metal or high-strength steels may require a different type of electrode to ensure strong and durable welds.

When welding mild steel, 6011 welding rod provides excellent penetration and produces a strong weld with minimal spatter. It’s also suitable for welding galvanized steel, but be sure to remove the zinc coating from the area being welded to avoid toxic fumes.

While 6011 welding rod can be used on stainless steel in certain situations, it’s not ideal for critical applications where corrosion resistance is vital. In these cases, a specialized stainless steel electrode should be used.

Cast iron can also be welded using 6011 welding rod, but it’s crucial to preheat the area being welded and use proper techniques to avoid cracking.

What are the Advantages of Using 6011 Welding Rod?

One of the most significant advantages of the 6011 welding rod is its versatility. This electrode can be used to weld mild steel, galvanized steel, sheet metal, and non-ferrous metals like aluminum and copper. Its ability to handle multiple metals makes it a go-to choice for welders who work with different materials and need an electrode they can rely on.

Not only is the 6011 welding rod versatile, but it’s also incredibly easy to use. With a stable arc that requires minimal effort to maintain, even beginners can use this electrode with ease. Plus, its fast-freezing slag ensures that welds cool quickly, reducing the risk of warping or distortion.

The 6011 welding rod is also known for its excellent penetration capabilities. It can easily penetrate thicker materials, making it ideal for welding thicker metals that require a strong and secure bond.

But that’s not all – the 6011 welding rod produces high-quality, clean welds that are visually appealing. The electrode creates smooth and consistent beads that require minimal post-welding cleanup.

Last but not least, the 6011 welding rod is cost-effective and readily available at local hardware stores.

It’s an affordable option for welders on a budget and is easily accessible for DIY enthusiasts who love working on their projects at home.

How to Use 6011 Welding Rod Properly?

Then it’s time to learn how to use 6011 welding rod like a pro. This versatile electrode is perfect for welding mild steel, galvanized steel, and other low-alloy metals. But to get the best results, you need to know how to use it properly. In this post, we’ll cover some essential tips and techniques for using 6011 welding rod, so let’s dive in.

Prepping Your Surface

Before starting to weld, it’s crucial to ensure that your surface is clean and free of any contaminants such as rust, oil, or grease. A dirty surface can cause porosity or weak welds, so take the time to prep your surface properly. You can use a wire brush or grinder to get the surface clean.

Choosing the Right Current

6011 welding rods can be used with both AC and DC currents, but using DC with reverse polarity will give you the best results. This current type allows for deeper penetration and better control over the weld pool.

Striking an Arc

When striking an arc with 6011 welding rod, remember to drag the electrode along the surface of the material being welded. This will help create a smooth and consistent weld bead. If you’re making multiple passes, make sure to remove any slag from the previous pass before continuing.

Adjusting Your Technique

One of the benefits of using 6011 welding rod is its ability to be used in multiple positions including flat, horizontal, vertical, and overhead. However, make sure to adjust your technique based on the position you’re working in for proper penetration and a strong weld. For example, when working in the overhead position, you may need to use a smaller diameter electrode and adjust your angle accordingly.

Paying Attention to Size and Storage

Finally, pay attention to the size and diameter of your electrode to ensure that it’s compatible with your welding machine. Using an electrode that’s too large can cause overheating and warping, while using one that’s too small can lead to weak welds.

Additionally, proper storage and handling of your welding rod can help prevent any damage or contamination that could affect its performance during use.

Common Applications for 6011 Welding Rod

Look no further than the 6011 welding rod. This popular choice among welders is perfect for a wide range of applications, from structural welding to automotive repairs. Here are seven common applications for 6011 welding rod that you should know about:

Firstly, if you need to weld beams, columns, or other structural components, the 6011 welding rod can produce a strong and durable weld that can handle heavy loads and stresses. Secondly, this type of welding rod is also great for welding both carbon steel and stainless steel pipes, making it a versatile choice for many piping projects.

Thirdly, whether you’re fixing machinery or repairing damaged equipment, the easy-to-use nature of 6011 welding rod makes it a popular choice for DIY projects and small repairs. Fourthly, farmers and agricultural workers rely on 6011 welding rod to repair and maintain farm equipment, including tractors, plows, and fences.

Fifthly, this type of welding rod is also commonly used in automotive repair work to repair frames, exhaust systems, and other vehicle components. Sixthly, shipbuilders often use 6011 welding rod to weld thick plates and produce strong, reliable welds that can withstand the harsh marine environment.

Lastly, 6011 welding rod is often used in industrial fabrication work such as manufacturing heavy machinery or constructing large structures due to its versatility and ease of use.

ZMQkPjjUJ_A” >

Conclusion

In summary, the 6011 welding rod is a must-have for any welder looking for versatility and reliability. Its unique composition allows it to penetrate deep into metals, making it ideal for thicker materials or those that are dirty or rusty. The beauty of this welding rod lies in its compatibility with both AC and DC currents, making it highly versatile and adaptable to a wide range of welding machines.

What sets the 6011 welding rod apart from other electrodes is its user-friendly nature. Even beginners can use this rod with ease thanks to its stable arc that requires minimal effort to maintain. Additionally, it produces high-quality, clean welds that are visually appealing.

The applications for the 6011 welding rod are endless. It’s commonly used in construction, agriculture, automotive repair work, shipbuilding, and industrial fabrication work. With proper techniques and careful attention paid to size and storage, you can achieve high-quality welds that meet your requirements.

Whether you’re an experienced professional or new to the world of welding, adding the 6011 welding rod to your toolkit will be a decision you won’t regret.