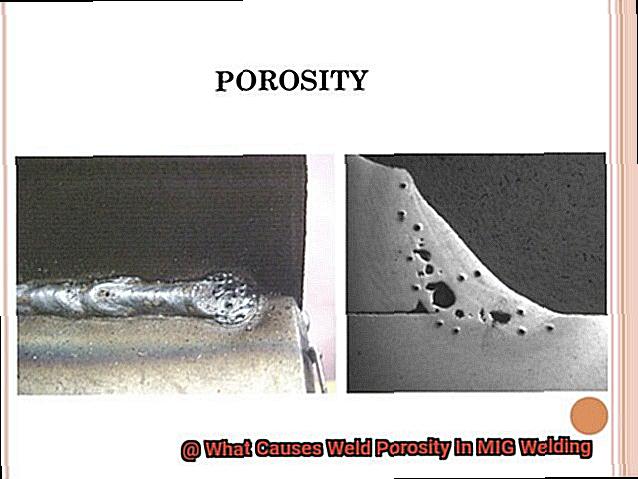

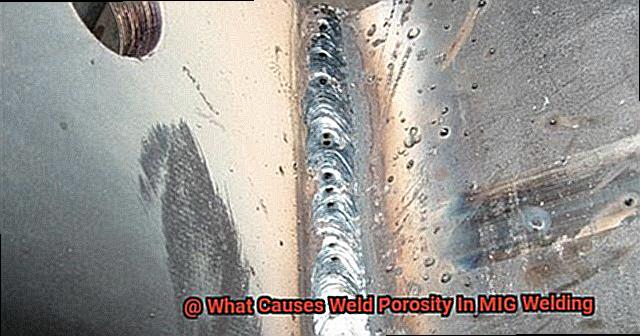

MIG welding is the go-to technique for many welders, thanks to its speed and efficiency. However, it is not without its challenges. One of the most common issues faced by welders is porosity – tiny holes that can appear on the surface of a weld.

Porosity occurs when gas becomes trapped in the weld metal, resulting in a cavity or void. This defect can have serious consequences on the quality and strength of the weld. But what causes it?

There are several factors that can contribute to porosity, including gas contamination, improper shielding gas, and incorrect welding techniques. It’s frustrating when you’re not sure what’s causing those tiny holes on your weld – but fear not. In this blog post, we’ll delve into the causes of weld porosity in MIG welding.

We’ll explore the properties of different gases that can cause porosity (such as Argon and CO2), and explain how to properly choose and utilize shielding gas to avoid this issue. We’ll also discuss how welding technique, metal preparation, and joint design play a role in preventing porosity.

By understanding these factors, you’ll be able to take steps to mitigate porosity and achieve high-quality welds with maximum strength and durability. Say goodbye to frustrating defects and hello to flawless welds.

Contaminants on the Surface of the Base Metal or Filler Material

Contents

Weld porosity is a common issue in MIG welding that can weaken the joint, and one of its primary causes is surface contamination of the base metal or filler material.

Contaminants such as rust, oil, grease, or moisture can react with the shielding gas and create gas pockets within the weld bead, which leads to porosity. To avoid this nightmare, proper preparation and cleaning of the metal surfaces are crucial before welding.

You can use wire brushes, grinding wheels, or chemical cleaning solutions to remove any surface contaminants. Additionally, you must ensure that the welding area is free from any moisture or humidity because they can trap hydrogen in the weld, causing porosity.

Improper storage and handling of the welding materials can also introduce contaminants into the process. Store metals in dry and clean environments to prevent rust and other surface contaminants from forming. Filler materials should be kept in their original packaging and stored in dry locations to avoid moisture absorption.

By taking these precautions with base metals and filler materials, you can guarantee successful welds without any defects. So, why risk faulty welds when you can prevent contamination and achieve structurally sound and long-lasting results?

Improper Shielding Gas Flow Rate or Composition

Today, we’re going to dive into the world of shielding gases and discover how improper flow rate or composition can lead to the dreaded villain of welding – porosity.

Picture this: you’re working hard on your weld, and suddenly, tiny bubbles start popping up everywhere. That’s porosity – and it’s caused by inadequate shielding gas. The superhero of your welding process, shielding gas, protects your weld from atmospheric contamination, provided it’s used correctly.

If the flow rate of your shielding gas is too high or too low, it can lead to porosity and weaken your weld. The ideal flow rate for MIG welding is typically between 20-30 cubic feet per hour (CFH). If the flow rate is too low, it won’t provide enough coverage and result in incomplete fusion and porosity. Conversely, if it’s too high, turbulence in the shielding gas can occur, leading to air contamination and porosity.

But here’s the kicker – the composition of your shielding gas is also crucial in preventing porosity. For MIG welding, a mixture of argon and carbon dioxide is commonly used because it provides excellent coverage and protection against atmospheric contamination. However, if the gas mixture isn’t balanced correctly, it can lead to porosity issues.

For instance, if there’s too much carbon dioxide in the mixture, it creates an excessive amount of gas that causes turbulence and air contamination – leading to none other than porosity. Similarly, if there’s not enough argon in the mixture, it can lead to inadequate coverage and incomplete fusion – once again resulting in pesky porosity.

Poor Welding Technique

While various factors can contribute to porosity in MIG welding, poor welding technique is one of the most common culprits. Let’s explore how improper welding techniques can lead to porosity and what you can do to avoid it.

One of the primary mistakes novice welders make is not cleaning the metal surface properly before welding. Any contaminants like rust, paint or oil left on the surface can result in porosity. Thus, it is crucial to clean the metal surface thoroughly before starting the welding process.

Proper gas coverage is also essential for preventing porosity. The shielding gas used in MIG welding protects the weld from atmospheric contamination. If there is not enough gas flow or if the nozzle is positioned incorrectly, it can cause porosity in the weld.

Moreover, incorrect travel speed and torch angle can also cause porosity in MIG welding. Too fast or too slow travel speeds can result in irregular heat distribution, leading to insufficient melting and incomplete fusion, thus causing porosity. Similarly, holding the torch at incorrect angles can cause a lack of penetration, leading to porosity.

To ensure high-quality welds without any defects like porosity, follow proper MIG welding techniques and procedures. This includes thorough cleaning of metal surfaces, using correct gas flow and nozzle position, maintaining correct travel speed and torch angle and following recommended welding procedures.

In conclusion, poor welding technique is a significant contributor to weld porosity in MIG welding. Novice welders must pay close attention to proper cleaning of metal surfaces, maintaining proper gas flow and nozzle position while ensuring correct travel speed and torch angle for flawless welds.

Aluminum and Its High Absorbency

Welding with aluminum is a popular choice, thanks to its lightweight and durable nature. However, aluminum is also known for its high absorbency, which can create weld porosity – a frustrating issue for any welder. But don’t worry, with proper techniques and attention to detail, it’s possible to achieve a flawless weld with aluminum.

The first step in avoiding weld porosity is to ensure that the base metal is cleaned correctly. Aluminum quickly oxidizes, forming a thin layer of oxide on its surface that hinders proper bonding between the filler material and the base metal. Mechanical or chemical cleaning methods can be used to remove surface contaminants. Mechanical cleaning involves using a wire brush or grinder, while chemical cleaning involves using solutions such as acetone or alcohol to dissolve oils or grease on the surface.

Using the correct filler material and welding technique is also crucial when working with aluminum. 5356 filler wire is a popular choice for welding aluminum because it has a low melting point and is more resistant to cracking. Maintaining a consistent arc length and travel speed is vital in preventing overheating and ensuring proper fusion between the filler material and the base metal.

By following these steps, you can significantly minimize or eliminate weld porosity when working with aluminum. Remember to take your time, focus on the details, and prioritize safety in your welding projects.

Materials with High Sulfur Content

If so, it’s essential to understand how sulfur can cause weld porosity and weaken your weld joint. Sulfur is a common impurity found in many metals and alloys, such as steel. When the metal is melted during the welding process, the sulfur in the metal vaporizes and creates gas pockets within the weld. These gas pockets are known as porosity, and they can reduce the strength of your weld joint and make it more prone to cracking.

To prevent weld porosity caused by high sulfur content, it’s important to use materials with low sulfur levels. Additionally, you should ensure that your welding equipment is properly calibrated and that you use the correct welding parameters for the materials being welded. By following these steps, you can create a strong and reliable weld that’s free from porosity and other defects.

However, sulfur is not the only impurity that can cause weld porosity. Other impurities such as phosphorus and carbon can also contribute to this problem. Therefore, it’s crucial for welders to be aware of these potential issues and take necessary precautions.

In some cases, preheating the material before welding can help reduce the amount of porosity caused by sulfur. However, it’s important to note that this technique should only be used under the guidance of a qualified welding professional, as preheating can also have negative effects on the overall quality of the weld joint.

EEhPfiPLoVE” >

Conclusion

In summary, weld porosity is a pesky problem that can compromise the strength of your MIG welding joint. A variety of factors can contribute to this issue, including surface contaminants on the base metal or filler material, improper shielding gas flow rate or composition, weak welding technique, aluminum’s high absorbency, and materials with high sulfur content.

To avoid these pitfalls and achieve flawless welds without any porosity defects, it’s crucial to take proper precautions.

This includes thoroughly preparing and cleaning metal surfaces before welding, using the correct gas mixture with recommended flow rate, maintaining proper travel speed and torch angle while following welding procedures to a T.

Additionally, when working with high sulfur content materials, it’s essential to choose low-sulfur materials and preheat under guidance.

By understanding these factors and taking necessary steps like using appropriate cleaning methods and storing metals in dry environments or choosing the correct filler wire for aluminum welding – you can ensure structurally sound and long-lasting results.