When it comes to military support personnel, welding is a critical skill that plays a vital role in ensuring the functionality and safety of military equipment and structures.

But what does it take to become a welder in this sector? Are the requirements different from civilian welders?

Firstly, it’s important to note that the military has its own set of standards for welding. This means that military support personnel must undergo specialized training to meet these specific requirements. It’s not just about being able to weld; it’s about meeting the high standards set by the military.

Secondly, physical fitness is crucial for anyone interested in pursuing a career as a welder in the military. The demands of welding can be challenging, including working in tight spaces and harsh and hazardous environments. Military personnel must be up for the task.

Finally, excellent attention to detail is essential for any aspiring military welder.

Welding is a high-precision skill that requires intense concentration and focus. One mistake could mean the difference between life and death on the battlefield.

In conclusion, becoming a welder in the military support personnel requires rigorous training, physical fitness, and exceptional attention to detail. It’s not an easy path, but it can be incredibly fulfilling and rewarding for those who are up for the challenge.

So if you’re ready to step up and meet the high standards set by our armed forces, consider exploring this exciting career path.

What is Welding?

Contents

Welding is more than just melting two pieces of metal or thermoplastics together.

It’s a highly skilled and fascinating process that requires expertise, precision, and technical knowledge. In the military, welding is a critical skill that plays an essential role in supporting operations by ensuring that vehicles, equipment, and infrastructure are properly maintained and repaired.

The welding process involves heating and melting the surfaces to be joined with high-temperature heat sources such as a gas flame, electric arc, or laser beam. As the melted edges cool, they fuse together to create a strong bond.

Military support personnel who specialize in welding undergo rigorous training to acquire the necessary skills and knowledge. This includes both basic training to provide foundational understanding of welding techniques and advanced welding school to teach specific military welding skills.

In addition to physical fitness requirements, military welders must have excellent hand-eye coordination and dexterity, as well as the ability to read blueprints and technical drawings to ensure precise specifications are met. The importance of welding in the military cannot be overstated.

It’s used in the construction and repair of tanks, ships, aircraft, and other military vehicles. Welding is also essential in the fabrication of weapons and ammunition, as well as in the construction of military bases and structures.

Without skilled welders, the military would not be able to maintain its equipment and infrastructure at peak performance levels. Those who excel in this field make an enormous contribution to maintaining the readiness of our military forces.

It’s physically demanding work that requires strength and stamina to hold heavy tools and equipment for extended periods. But for those who are passionate about welding, it’s a rewarding career that allows them to play an important role in serving their country.

What Are The Requirements To Become A Welder In The Military?

Before you start, there are certain requirements that you need to meet. Firstly, you must be at least 17 years old and have a high school diploma or equivalent.

This is the basic requirement that all interested individuals must meet. In addition to this, you must also pass the Armed Services Vocational Aptitude Battery (ASVAB) test with a score of at least 31.

These requirements ensure that only the most qualified candidates can become military welders. Once you have met these basic requirements, your training to become a welder in the military will begin.

This training typically takes place at various military bases and lasts for several months. During this time, you will learn all the necessary welding techniques and safety procedures required for military welding jobs.

You will also receive hands-on experience with different welding tools and materials. It’s important to note that there are different levels of welding positions within the military.

Some positions may require more advanced welding skills or certifications such as the American Welding Society (AWS) certification. Therefore, if you want to advance your career as a military welder, you may need to complete additional training or obtain certifications that prove your expertise.

Physical Requirements

If you have your sights set on a career as a military welder, it’s important to know that physical fitness is a fundamental requirement for success in this field.

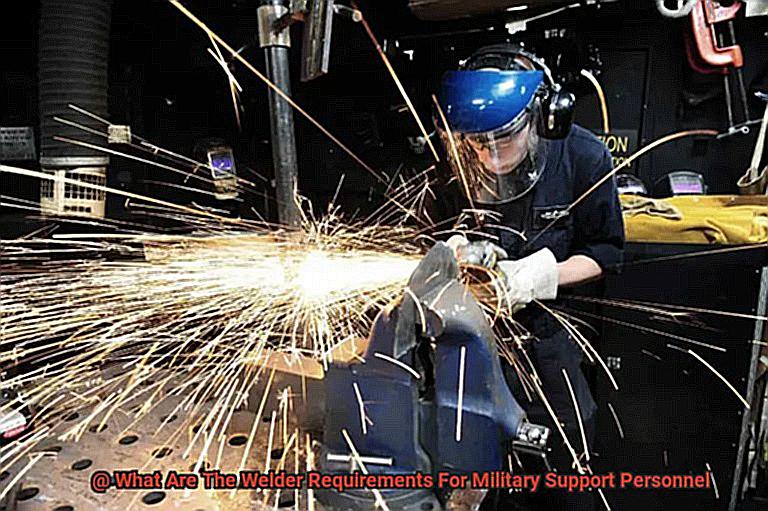

Welding is a precise craft that demands an acute sense of detail, making good eyesight and hand-eye coordination essential. Additionally, welders must possess steady hands and excellent manual dexterity to manipulate tools and materials with remarkable accuracy.

However, welding is not just about having the right skills. It can be physically demanding, requiring welders to lift heavy equipment, work in awkward positions, and stand for long periods.

They may also need to climb ladders or scaffolding to reach welding areas. Therefore, it’s imperative for welders to be physically fit and capable of withstanding the job’s physical demands.

When it comes to welding in the military, safety is also paramount. Welders must follow safety procedures and wear protective gear at all times to protect themselves and others in the workplace.

This entails wearing helmets, gloves, safety glasses, and flame-resistant clothing. In summary, physical requirements are an essential aspect of welding in the military.

Additionally, welders must follow safety procedures and wear protective equipment at all times.

Technical Aptitude Requirements

It refers to an individual’s ability to comprehend and apply technical concepts and skills effectively. For welders, this means being proficient in welding processes, equipment, materials, and safety practices.

To qualify for the role of military support personnel welder, one must have completed a formal welding training program and hold certification from a reputable organization such as the American Welding Society. Moreover, welders must have hands-on experience with various welding techniques like gas tungsten arc welding, shielded metal arc welding, gas metal arc welding, and flux-cored arc welding.

Apart from technical expertise, support personnel welders must also have a solid foundation in mathematics and be able to read blueprints and technical drawings accurately. They must possess excellent hand-eye coordination and dexterity to manoeuvre tools and equipment skillfully.

In addition to these requirements, military support personnel welders must be physically fit to handle the demands of the job. This includes lifting heavy equipment and materials and working in adverse conditions such as confined spaces, at heights, in extreme temperatures, and noisy environments.

This encompasses proficiency in various welding techniques, formal training programs, familiarity with technical drawings and blueprints, excellent hand-eye coordination, physical fitness, and the ability to work under adverse conditions.

Certification Standards

Welding in the military requires a level of precision and skill that cannot be compromised. It is vital that the equipment used can withstand extreme conditions and perform flawlessly in life-threatening situations.

This is where certification standards come into play, ensuring that only the most highly skilled and qualified welders are entrusted with the critical task of welding military equipment and structures. At the forefront of these standards is the American Welding Society (AWS) D1.1 Structural Welding Code – Steel, the primary certification standard for military welders.

This code sets out rigorous requirements for welding structures made from steel, including welder qualification requirements, visual inspections, and destructive testing. But that’s not all.

Depending on their specific job duties, military welders may need to be certified under other codes such as AWS D17.1 Specification for Fusion Welding for Aerospace Applications.

These certifications are not just a one-time requirement; regular testing and recertification processes ensure that welders maintain their qualifications and continue to meet high standards.

Certification standards serve as a benchmark for quality and safety in military welding. They guarantee that welders possess the necessary skills and knowledge to perform their duties with precision and reliability, ensuring the safety of our military personnel and equipment.

They are a testament to the level of expertise required to perform this critical task successfully.

xCjPhCUnhos” >

Conclusion

To sum up, embarking on a career as a military support personnel welder may not be for the faint of heart, but it can be an incredibly fulfilling and gratifying experience.

Welding is much more than just fusing two pieces of metal together; it’s a complex and captivating process that necessitates expertise, accuracy, and technical know-how. Military welders must undergo specialized training to meet the specific requirements set by the armed forces.

Along with meeting physical fitness standards, military welders must have exceptional hand-eye coordination and dexterity while also being able to read blueprints and technical drawings to ensure precise specifications are met. Physical fitness is critical for anyone interested in pursuing welding as a career in the military.

The demands of welding can be arduous, including working in cramped spaces and harsh environments that pose various hazards. Furthermore, paying close attention to detail is essential because one mistake could mean the difference between life and death on the battlefield.

They ensure that welders possess the necessary skills and knowledge to carry out their duties with precision and reliability, guaranteeing the safety of our military personnel and equipment.