Whether you’re in the manufacturing industry or have ever had a metal repair, chances are you’ve come across spot welding. This technique involves creating small, localized welds at specific points to join two pieces of metal together.

But what sets spot welding apart from other methods? In this post, we’ll explore two key advantages of spot welding: speed and precision.

Let’s begin.

Advantages and Disadvantages of Spot Welding:

Contents

Spot welding is a widely used and well-known welding technique, which, like any other method, has its own set of advantages and disadvantages. This process involves joining two or more pieces of metal by applying pressure and heat to create a bond. It has been in use for over a century and has become an essential part of the manufacturing industry due to its efficiency and cost-effectiveness.

One of the major benefits of spot welding is its minimal heat affected zone in the base metal. In simple terms, this means that the areas surrounding the weld are not significantly affected by heat, reducing the risk of distortion or damage. What’s more, spot welding is a straightforward process that can be operated automatically or manually, making it accessible for individuals with different skill levels.

Another advantage of spot welding is its versatility. It can be used to join various types of metals together, making it a valuable tool in the manufacturing industry. Additionally, this method has a high production rate, making it ideal for mass production. It is also efficient for thin metals, and multiple metals can be welded simultaneously, saving time and increasing productivity.

However, spot welding does have some drawbacks that must be taken into consideration. One of the main limitations is its suitability only for thin metals. This means that thicker materials may not be accurately and efficiently welded with this method, limiting its versatility. Another disadvantage is the higher installation costs. The initial setup cost for spot welding equipment can be expensive, making it not as feasible for small businesses.

Moreover, spot welding can cause deformation on certain materials, depending on the heat and pressure applied during the process. This can affect the appearance and structural integrity of the welded pieces. Furthermore, it is sensitive to changes in power supply, which can result in weak welds and compromise the strength of the joint.

In conclusion, spot welding offers numerous benefits such as minimal heat affected zone, high production rate, versatility, and cost-effectiveness compared to other welding methods.

Advantages of Spot Welding:

Are you in the manufacturing industry and searching for a speedy, secure, and cost-effective way to join metal materials? Look no further than spot welding. This unique welding process has been in use for over a century and remains a top choice for manufacturers across various industries. But what sets spot welding apart? Let’s delve into its benefits.

Simplicity and Affordability:

One of the greatest advantages of spot welding is its simplicity and affordability. Unlike other welding methods that require specialized equipment and extensive training, spot welding can be easily performed with basic tools and minimal training. This not only saves time and money but also makes it accessible for small businesses and startups.

Compatible with Lightweight Metals:

Spot welding is compatible with a wide range of metal materials, including lightweight metals like aluminum and copper. This is especially advantageous in industries where weight plays a crucial role, such as automotive and aerospace. With spot welding, these metals can be joined together without causing any damage or distortion, ensuring the integrity of the final product.

Uniform Joints:

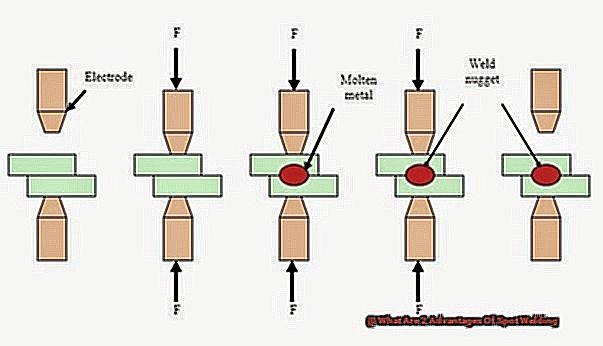

Spot welding creates uniform joints that are strong and durable. The electric currents generated from two copper alloy electrodes create heat on the surface of the metals, melting them together at specific spots. This results in a consistent and reliable bond that can withstand high levels of stress and pressure.

Cost-Effective Production:

Due to its simplicity and speed, spot welding is highly efficient for manufacturers in terms of production cost. With the ability to join metal pieces quickly, it allows for a high production rate, saving both time and labor costs. Additionally, its compatibility with various metal materials means businesses don’t have to invest in different welding methods for different projects, further reducing costs.

In conclusion, spot welding offers numerous advantages that make it a top choice for manufacturers in various industries.

Disadvantages of Spot Welding:

Spot welding, while hailed as a manufacturing industry superhero, is not without its limitations. As a seasoned expert in this field, I have delved into the potential drawbacks of this widely used welding method and am eager to share my discoveries with you. From material thickness and composition to surface preparation and brittleness, let us delve into the constraints of spot welding.

Material Thickness and Composition:

Despite its efficiency and versatility, spot welding does have limitations when it comes to material thickness and composition. This method is most effective when joining similar thicknesses and compositions of metal sheets. Attempting to weld varying thicknesses or compositions can result in weak or inconsistent welds, compromising the overall strength and stability of the joint.

Need for Pristine Surfaces:

One crucial aspect of achieving a robust and secure weld is ensuring clean surfaces. Spot welding demands that metal sheets be free of any impurities such as rust, oil, or paint. Failure to remove these contaminants before welding can result in weak spots or hinder proper melting of the metal, leading to subpar welds. This makes surface preparation a critical step in the spot welding process, adding time and effort to the production process.

Susceptibility to Brittleness:

Another potential drawback of spot welding is its susceptibility to brittleness. Improper dwell time (the duration of pressure and current application) can result in a brittle weld. This can be a significant concern for industries where flexibility and durability are vital, like automotive or aerospace. To avoid this issue, precise control and monitoring of the dwell time are crucial.

Comparison to Other Welding Methods:

In terms of density, spot welding falls short compared to other types of welding, such as continuous joints. Continuous joints offer a more uniform distribution of heat and pressure, resulting in higher density welds.

Conclusion

In conclusion, spot welding is a superhero in the world of welding techniques, offering numerous advantages that make it a highly sought-after method in the manufacturing industry. Its minimal heat affected zone, versatility, and high production rate make it a cost-effective and efficient choice for joining metal materials. However, like any other technique, spot welding does have its limitations. These include its suitability for only thin metals, higher installation costs, and potential deformation of certain materials. Despite these drawbacks, spot welding remains a top choice for manufacturers due to its simplicity, affordability, compatibility with lightweight metals, and ability to create uniform joints.

But what sets spot welding apart from other methods is its unique combination of benefits that cater to the specific needs of manufacturers. Not only does it offer a low heat input which reduces the risk of warping or distortion in delicate materials, but it also boasts a high production rate that allows for faster completion of projects. And let’s not forget about its versatility – being able to join different types of metals together makes it an invaluable tool for various industries.

However, as with any process, there are always limitations to be considered. Spot welding may not be suitable for thicker materials or may require higher installation costs compared to other methods. But these trade-offs are often outweighed by its efficiency and effectiveness in creating strong and uniform joints.

In summary, spot welding has solidified itself as an essential technique in the manufacturing world due to its unique advantages and compatibility with lightweight materials. We hope this blog post has provided valuable insights into the benefits of spot welding and helped you understand why it continues to be a popular choice among professionals in the industry.