I don’t think I need to tell you there are a lot of people in the world who have their own opinions on what color tungsten you should wear for your welding.

Like really, a lot. It’s crazy why people argue about nit picky stuff when there are so many more important things in life.

I mean, welding with the wrong set of tungstens could cause serious injuries.

What color tungsten do you use for stainless steel?

Contents

It’s excellent for welding carbon steel, stainless steel, and even titanium, but metallurgists still prefer it for welding steels containing nickel because the nickel tends to oxidize, and that oxidation of steel is the cause of rust.

Consequently, corrosion inhibitors are usually added to steel during pre-matte treatment to prevent rust.

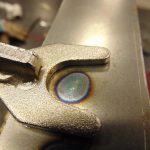

The electrical properties of ceriated tungsten vary , depending on the addition of other elements.

Depending on the degree of substitution, it ranges between very pure tungsten, which is very brittle and highly oxidation-resistant, and very pure thorium, which is ductile and magnetic.

What kind of gas is used to weld stainless steel?

The ideal gas composition for hand TIG welding austenitic stainless steel is argon and hydrogen.

Shielding gas infused with hydrogen aids in the scavenging of oxygen from the vicinity of the weld pool, resulting in a much cleaner weld surface and reducing the amount of post-weld cleaning.

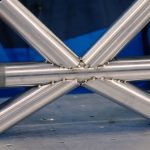

The addition of hydrogen to the shielding gas aids in the weld heat-affected zone, making the weld bead homogeneous, flat, and shrink-fit to the base material. This combination produces a smooth, clean weld defect-free finish.

What color tungsten is best for steel?

The 2% thoriated (color code red) tungsten electrode is an all-purpose tungsten electrode.

This electrode is excellent for welding mild steel. It is suitable for all welding operations and is ideal for preheating.

The 2% thoriated color code red tungsten electrode lasts even longer than other electrodes, and its compact heat-resistant design is perfect for portability.

Can you use red tungsten for stainless steel?

Red Thoriated TIG Welding Electrodes are among the most widely used electrodes on the market.

They are suitable for welding carbon steel, low-alloy stainless steel, aluminum, and alloyed stainless steel. For the same reason, the electrodes usually perform well in welding aluminum alloy and mild steel.

Some welders have discovered that it works effectively as filler metal in ERW processes too. The advent of TIG and plasma arc welding was different for the manufacturing sector.

Do you weld stainless on AC or DC?

A direct-current (DC) arc runs between the tungsten electrode in the workpiece and the tungsten electrode on the welding wire.

Most arc welding processes used today use DC arcs, such as MIG (metal inert gas), MAG (metal active gas), and TIG (tungsten inert gas).

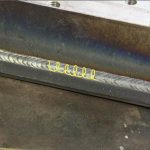

TIG welding is especially popular for stainless steel, as it produces very thin, smooth weld beads and little spatter (burning).

“Direct Current Electrode Negative” or “DCEN” arcs are also known as “DC” arcs because they produce a continuous current of positive polarity that is similar in function to “Direct Current”, a direction of electricity that flows from positive to negative.

The electrode features a negative pole, which makes the arc negative and thus produces the piercing effect of the weld.

The “negative” polarity produces the heat as the electric current travels from the positive electrode to the negative.

The weld pool created is deep and narrow, as the electricity travels to the metal before setting it up to melt.

What electrode would work best for stainless steel?

Stick welding stainless steel using a 309 or 312 SMAW electrode provides better cost-effectiveness compared to other electrodes.

It has excellent strength and fracture resistance, and it can weld up to 14 mm thick metals.

A 303 electrode has good welding properties on general carbon steel, and it has much less resistance than an SMAW electrode to cracking and spicing. A 305 or 305M electrode can improve weld properties on 4140 and 4130 steels.