Do you have an old or broken weld that you’d like to fix or repair? Try these tips on How to Remove Welding to find out if you can do it yourself!

If you know ahead of time what kind of weld you have and how to remove it, Welding is an applicable skill that many hobbyists and do-it-yourselfers wish to acquire, and it’s also a useful qualification in any programming or engineering career.

Welding is a skill that can be applied to many different industries, whether you’d like to create an object out of metal or plastic.

However, welding is a process that should only be done by a pro with the right tools, knowledge and know-how, and precautions.

How to Remove Welding

Contents

Mechanical methods

The kind of weld you’re working with also determines which method may be best: for instance, thin sheets can be cut using a grinder, but thick sheets may require a saw or plasma cutter.

As an example, spot-welded sheets are difficult to cut through. The separation is sometimes accomplished by drilling into the sheets themselves.

To cut through the cutting process in sheet-metal work, you can use methods such as torch cutting, plasma cutting, or drills.

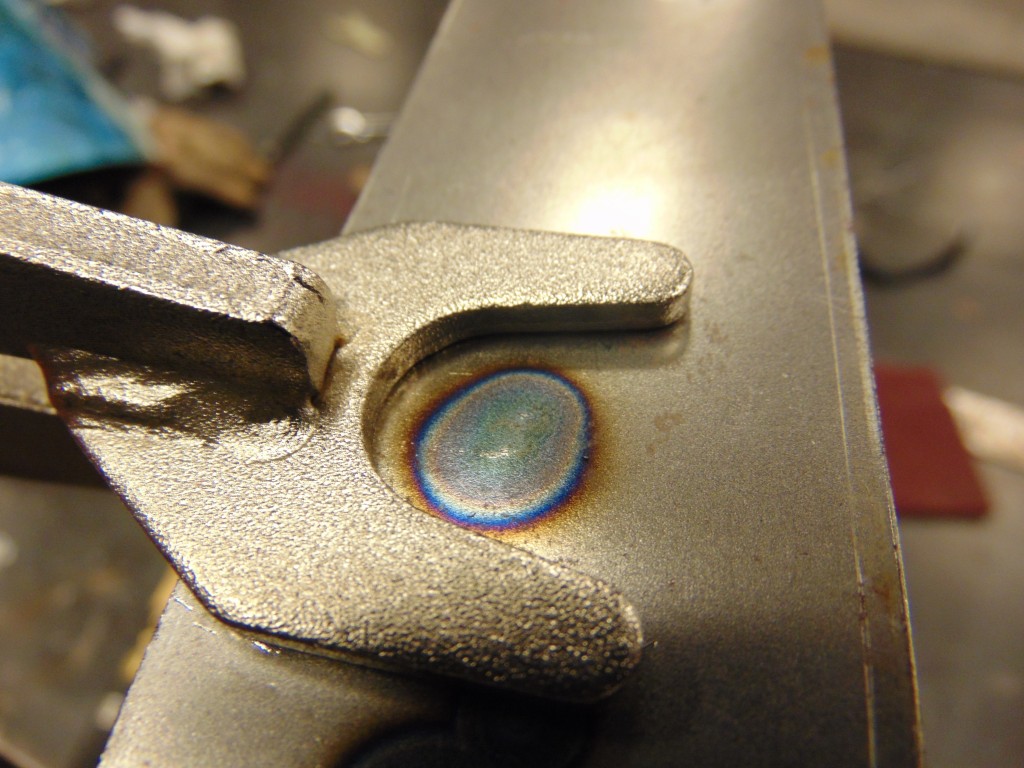

Thermal methods

A greek term that meaning “heat” is “therm.” To undo welding using thermal methods, you must have heat. This can be done with torches and plasma cutters.

Thermal procedures need the weld to be exposed to a high temperature for long enough for it to be melted enough to break off cleanly.

This method may not be suitable if the weld is very strong or if there are too many rivets or welds covering a small area.

Oxy-acetylene torches or plasma cutters heat up the tool and melt the welding metal.

This softens the weld and lets you remove it by grinding or sawing. Thermal methods of removing welding also depend on the welding technique.

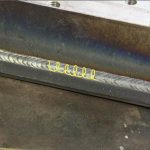

For example, gas metal arc welding (GMAW) involves using a welding torch to create the weld. In contrast, shielded metal arc welding (SMAW) involves using an electrical arc between two electrodes.

Torch cutting

The torch uses a combination of two gases , oxygen and acetylene. The oxygen feeds the oxygen and acetylene gasses together, and the resulting flame cuts through the weld.

Torch cutting is advantageous in that it is both quick and inexpensive. When the torch cutting process is completed, the metal pieces need to be cleaned.

The equipment is also less expensive, more portable, and more powerful, so more weld jobs can be completed faster and more accurately.

Plasma cutting

When direct current is used, an arc is created between the arc and the work piece.

When the arc is struck, it creates a stream of plasma in the work piece. When the arc is struck, the plasma stream moves laterally along the piece of metal and melts it.

Compared to hand torches, plasma cutters are safer, easier to use and have better cutting quality.

They’re safer and more cost-effective since no combustible gases are required to operate them.

How to Remove Welds with a circular saw or a grinder

Angle grinders are often used to cut through cast iron, steel, stainless steel, and even malleable iron.

Cutting and shaping metal surfaces requires powerful tools.

Consequently, the base metal does not melt.

- Cut where you’ve marked, and be careful not to cut the parent metal. It may take several passes to completely remove the weld.

- Use clamps or vices to hold the panels in place.

- Wear your safety goggles, protective gloves and face mask to avoid injuries.

- Using the socket, insert your tool into the metal.

- Allow the grinder to slowly move over the metal, removing it bit by bit.

- The parent metals should still become molten during the cutting process, but the heat will dissipate after the cut is complete.

- Take a step ladder and climb into the socket. Use a tape measure to measure the distance you need to remove, then mark it with a pen. Use a reciprocating saw to cut it.

- The cutting disc might be damaged , so you’ll need to replace it with a new one.

- When not in use, turn the motor off to avoid overheating.

- Friction, not the grinder, is what generates the extreme heat.

How to Remove welds without grinders

Drilling or employing plasma and oxy-acetylene torches as cutting tools will have to be done by professionals.

Using a bandsaw or a belt grinder is a lot faster. It cuts metal much more quickly than a hand grinder, so it’s often a better alternative.

- Once you’ve marked where you plan to remove a weld, use a grinder with a diamond wheel to cut the weld. Be prepared to weld over the cut once you’re satisfied with your result – this will ensure the weld can’t spread.

- You don’t need any special equipment, and this repair can be done with a grinder or a file.

- After that, place the metal pieces where they need to be.

- Typically, you may use a cold chisel, a rounded metal object, or a puller to remove welds in this step.

- The gas tank should then be filled up with water. The tank should be filled with water to remove heat from the torch.

- The torch must be turned all the way down before touching the piece.

- To begin, turn on the compressor and prop the compressor’s tank up against the piece being cut. If water is in the line being cut, shut off the compressor and wait for the water to drain. Once the tank is empty, connect the compressor to the piece being cut. Try to keep some pressure in the line. Once the compressor has been running for 10 or 15 minutes, you can begin the removal process.

- Adjust the torch’s flame as needed.

- A saw, torch, or any other equipment that you use to remove welds can be extremely dangerous as well as costly.

- To prevent mistakes and to stay safe, wear protective gloves when drilling or cutting.

- Repeat this process until you’ve removed all the welds.

- Let the metals cool down before working on it, and you may be able to work without gloves. Always wear protective clothing when working with metals. Gloves, safety glasses, and goggles are all very important.

- Because the machinery you’re using create a a lot of heat, touch them just after they’ve been cut is dangerous.

Which process is better for you?

To reweld the components after the weld is removed, you can use a different welding process or create an entirely new one.

Welding the metals together without first removing the rest of the metal is technically called brazing, but it’s quite different from welding.

If the welds are really strong or if you wish to undo sheets that are joined together, you may have to drill or grind them open.