Calling all car enthusiasts, mechanics, and DIY enthusiasts. Have you ever found yourself in a bind where you need to join exhaust pipes but don’t have the welding equipment or expertise to get the job done? Fear not, because there are several easy and effective ways to join exhaust pipes without welding.

Don’t let your lack of welding skills hold you back from making necessary repairs or modifications to your vehicle’s exhaust system. In this article, we’ll explore some of the best methods for joining exhaust pipes without welding, such as clamp joints, slip joint connectors, and flange connections.

We’ll delve into the advantages of each technique and provide step-by-step instructions to help you achieve a flawless connection that can withstand the test of time. Additionally, we’ll share some common mistakes to avoid and offer tips and tricks for achieving a seamless fit.

Whether you’re a seasoned mechanic or a beginner DIY enthusiast, this article is sure to be an invaluable resource for you. So let’s dive into the world of joining exhaust pipes without welding and discover innovative ways to keep your car running smoothly.

What is Joining Exhaust Pipes Without Welding?

Contents

- 1 What is Joining Exhaust Pipes Without Welding?

- 2 Advantages of Joining Exhaust Pipes Without Welding

- 3 Different Methods for Joining Exhaust Pipes without Welding

- 4 Clamps for Joining Exhaust Pipes without Welding

- 5 Sleeves for Joining Exhaust Pipes without Welding

- 6 Adhesives for Joining Exhaust Pipes without Welding

- 7 Conclusion

Joining exhaust pipes without welding is a practical and accessible practice that can help you save money and time. Let’s explore some of the most popular methods.

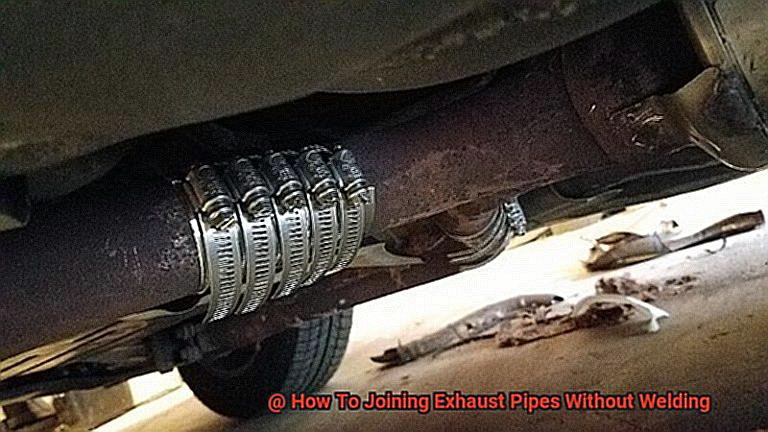

Clamping is one of the most common ways to join exhaust pipes without welding. By using clamps, you can securely fasten exhaust pipes together with ease. It’s like giving your pipes a giant metal hug. Alternatively, sleeves can be used, which are tubes that fit over the ends of two exhaust pipes and are secured in place using clamps or other fasteners. It’s like putting on a sleeve for your arm, but for your exhaust pipes.

For those who need something different, adhesives can also be used to join exhaust pipes without welding. These special adhesives are designed to withstand high temperatures and provide a strong bond between the two pieces of metal. It’s like using super glue for your exhaust system.

It’s important to keep in mind that each method has its own advantages and disadvantages, and the choice of which method to use depends on several factors such as the type of pipe material, the diameter of the pipe, and the intended use of the exhaust system. It’s crucial to consider all options before selecting which method to use.

Advantages of Joining Exhaust Pipes Without Welding

Look no further. Joining exhaust pipes without welding can save you time, money, and offer several advantages that may surprise you.

Firstly, welding requires specialized equipment and skilled labor, which can add up costs quickly. In contrast, using alternative methods such as clamps or couplers can avoid these expenses altogether. This means you can have more money in your pocket and a quicker installation process.

Another significant advantage of joining exhaust pipes without welding is the ease of disassembly and maintenance. Welded exhaust systems are challenging when it comes to repairs or replacements since they cannot be easily taken apart. However, using clamps or couplers allows for quick disassembly with standard tools, making maintenance and repairs much more convenient and cost-effective.

Customization is another area where joining exhaust pipes without welding shines. Welding limits the angles and positions in which pipes can be connected, whereas couplers and clamps offer greater flexibility in terms of positioning and angle adjustments. This allows for greater customization of the exhaust system to fit specific vehicles or performance needs.

Different Methods for Joining Exhaust Pipes without Welding

Luckily, there are several methods available for joining exhaust pipes without welding, each with its own set of advantages and disadvantages. Let’s delve into the different ways you can join your exhaust pipes without welding.

One of the most popular methods is using exhaust clamps. These clamps come in various sizes and shapes to fit your exhaust pipe’s diameter. They work by clamping down on both ends of the pipes, creating a secure seal. However, it’s crucial to note that not all exhaust clamps are created equal, and some may not be suitable for high-performance or turbocharged engines.

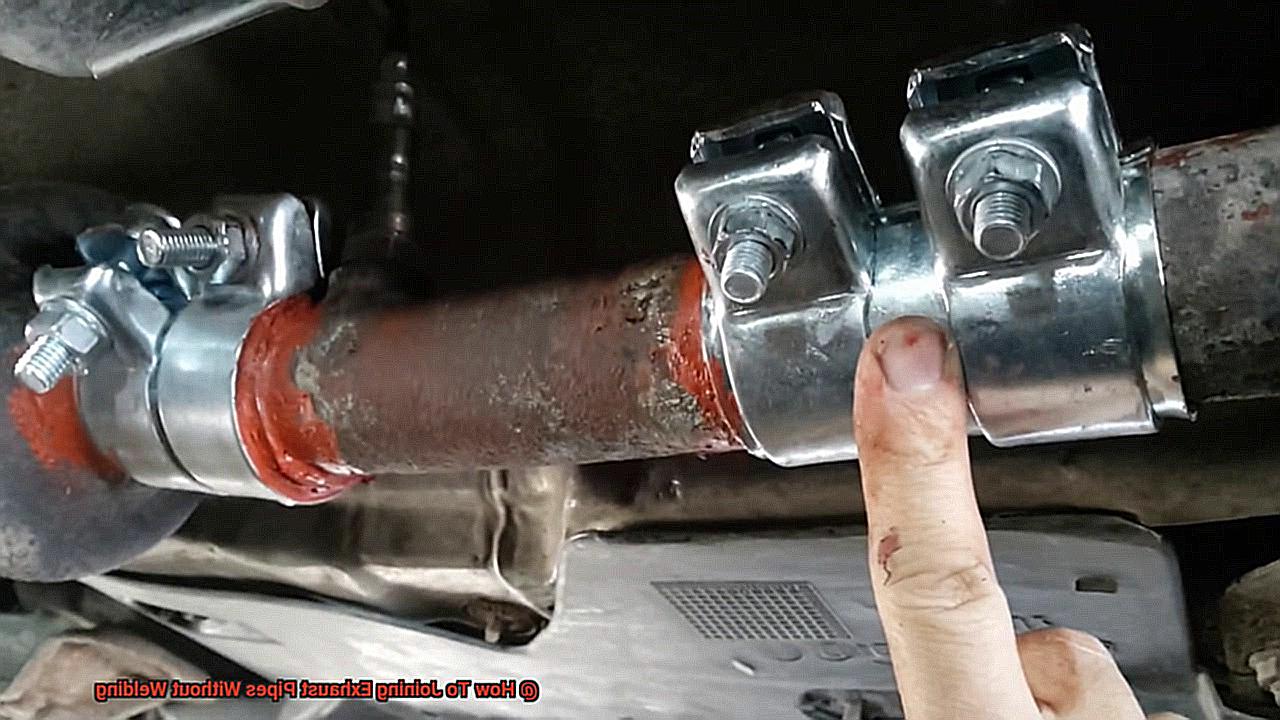

For those looking for a sturdier option, consider using exhaust sleeves. These tubes slide over the ends of your exhaust pipes and connect them together. Made from high-grade stainless steel, they can withstand high temperatures and pressure. One of the benefits of using exhaust sleeves is that they provide a leak-proof seal and can be easily removed or replaced if needed.

If you’re a DIY enthusiast, exhaust tape or sealing paste may be the option for you. Exhaust tape is a heat-resistant tape that can be wrapped around the joint between two pipes to create a seal. Sealing paste, on the other hand, is a viscous substance that can be applied to the joint before connecting the pipes. Both methods work by filling in any gaps between the pipes and creating a seal that prevents leaks.

Finally, mechanical connectors are also available for joining exhaust pipes without welding. These connectors come in different styles, such as ball and socket joints or flex couplings, and connect two pipes together using bolts or clamps. Mechanical connectors are typically easy to install and can provide a secure connection between pipes.

Clamps for Joining Exhaust Pipes without Welding

If you’re looking for a reliable and easy way to join exhaust pipes without welding, then clamps are your answer. As an expert in the field, I suggest using U-bolt clamps, band clamps, or V-band clamps for the job.

U-bolt clamps got their name from their unique shape – think of a U with two bolts on each end. These clamps are incredibly versatile and can be used to connect pipes of different sizes. Installing them is a breeze, and they can be tightened with a socket wrench. It’s like having an adjustable wrench in your toolbox – dependable and adaptable.

Band clamps are circular with a tightening screw that secures the two ends of the pipe together. They provide an exceptionally tight seal and can be removed and reused with ease. Think of them as your trusty screwdriver – straightforward but effective.

V-band clamps are specifically designed for high-performance exhaust systems that need to withstand extreme temperatures and pressure. They have a V-shaped groove on one end and a mating flange on the other, making them an efficient option for secure connections that are easy to install and remove. V-band clamps are like power tools – strong and dependable.

Regardless of which clamp you choose, it’s vital to ensure that the connection is tight and secure. Loose connections can lead to exhaust leaks, which can cause poor performance, increased emissions, and even engine damage.

Sleeves for Joining Exhaust Pipes without Welding

When it comes to joining exhaust pipes without welding, there’s no need to compromise on durability or aesthetics. Sleeves are a popular option that can provide a secure and reliable connection, with the added benefit of being easily removable and replaceable if necessary.

Sleeves are essentially metal tubes that slide over the ends of the pipes and connect them together. They come in a variety of sizes and materials, including stainless steel, aluminized steel, and mild steel. However, it’s crucial to choose the correct size and material for your specific application to ensure a snug fit that won’t damage either pipe.

To install a sleeve, you’ll need to clean the ends of the pipes with a wire brush or sandpaper to remove any rust or debris. Then apply a high-temperature silicone sealant around the end of each pipe to create a tight seal. Slide the sleeve over one end of the pipe until it reaches the sealant, then repeat the process with the other pipe. Slide the sleeve over both ends until they meet in the middle and finally tighten clamps around both ends of the sleeve to secure the connection.

One advantage of using sleeves is that they provide a more aesthetic appearance than other methods like hose clamps or wire ties. Additionally, they’re more flexible than welding, which requires cutting and grinding to remove connections. However, it’s important to note that sleeves may not be as strong as welded connections and can potentially leak if not installed correctly. Therefore, they may not be suitable for high-performance applications where maximum flow is required.

Overall, sleeves are a reliable option for joining exhaust pipes without welding and can provide a secure and durable connection when installed correctly.

Adhesives for Joining Exhaust Pipes without Welding

Lucky for you, adhesives are a fantastic alternative method for connecting metal surfaces together. With many adhesives on the market today specifically formulated for high-temperature applications like exhaust systems, you have a variety of options to choose from.

One adhesive commonly used for joining exhaust pipes is a two-part epoxy. This adhesive creates a strong, permanent bond between metal surfaces, making it an excellent choice for exhaust systems. However, before applying the adhesive, it’s important to clean the surfaces thoroughly to ensure maximum bonding power. Any grease or oil residue can weaken the strength of the bond.

Another popular adhesive used for joining exhaust pipes is high-temperature silicone sealant. This type of adhesive can withstand temperatures up to 600 degrees Fahrenheit and is specifically designed to fill gaps between metal surfaces. It can also be used to seal joints and connections in an exhaust system to prevent leaks.

It’s essential to note that while adhesives can be a useful solution for joining exhaust pipes without welding, they should not be used as a replacement in all situations. For example, if the joint will be under significant stress or strain, or if there’s a risk of excessive heat buildup, welding may be necessary to ensure a safe and secure connection.

Overall, adhesives are an effective solution for joining exhaust pipes without welding. By choosing the right adhesive for your application and following all manufacturer instructions carefully, you can ensure a strong and reliable bond.

Lni5W8xDpXY” >

Conclusion

In conclusion, learning how to join exhaust pipes without welding is a valuable skill that can save you both time and money while ensuring your vehicle runs smoothly. There are several methods available, including clamps, sleeves, and adhesives, so you don’t need to be an expert welder to make necessary repairs or modifications.

Clamping is a popular way to join exhaust pipes without welding as it’s easy to install and provides versatility in connecting pipes of different sizes. Sleeves are another reliable option that offers a secure connection while maintaining an aesthetic appearance. Adhesives like high-temperature silicone sealant and two-part epoxy create a permanent bond between metal surfaces.

Joining exhaust pipes without welding also has several advantages over traditional welding methods. It saves on costs, allows for easier maintenance and customization, and gives greater flexibility in design.

No matter which method you choose, it’s crucial to select the right one for your specific needs and engine type. Loose connections can lead to leaks that cause poor performance, increased emissions, and even engine damage. Therefore, always ensure a tight and secure connection.