Do you have a passion for metalworking but lack access to a welder?

Fear not. Forge welding is an ancient technique that can be accomplished without one.

With the right tools, patience, and skill, you can join two pieces of metal through heat and pressure, without the use of filler material. Forge welding involves heating metal pieces to their melting point and then hammering them together to fuse them into a single piece of metal.

One way to do this is by using a gas or coal-fired forge. If you have the space and equipment at home, this method can be achieved with ease.

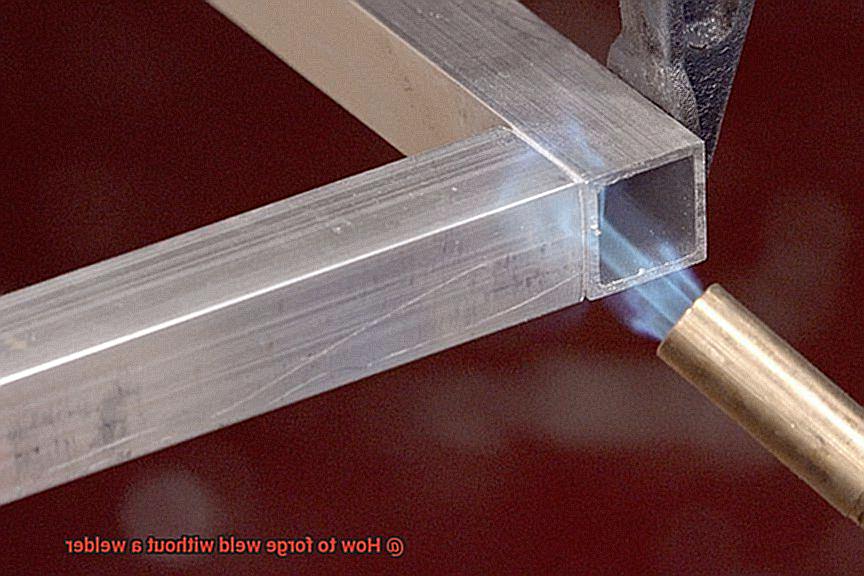

Alternatively, you can use a propane torch and hammer to apply pressure. While less precise than using a forge, this method can still produce impressive results in small workspaces.

Safety should always be your top priority when working with fire and hot metals. Make sure to wear appropriate protective gear and work in a well-ventilated area.

Impress your friends and family with unique metalwork creations that showcase your newfound skills.

What is Forge Welding?

Contents

Forge welding is a remarkable process that has been utilized by skilled metalworkers for centuries to create robust, long-lasting objects such as weapons, tools, and decorative items.

This technique involves heating and hammering two pieces of metal until they fuse together, resulting in one solid piece. Unlike other welding methods that rely on electricity or gas to heat the metal, forge welding requires a forge or furnace to heat the metal until it is malleable enough to be hammered into shape.

One of the most significant advantages of forge welding is that it can be done without the use of a welder, making it an ideal option for hobbyists and DIY enthusiasts who want to try their hand at metalworking without investing in expensive equipment. However, it’s important to note that forge welding requires skill, experience, and access to specialized tools such as a forge or furnace, anvil, and hammer.

Canister damascus is an excellent example of a technique that uses forge welding to create intricate patterns and textures in the finished product. This technique involves placing a mixture of powdered metals inside a steel canister, which is then sealed and heated in a forge.

The resulting billet can then be forged into a variety of shapes and patterns, creating unique and visually stunning pieces of metalwork. Forge welding is not only a practical welding technique but also an art form.

The process of heating and hammering the metal requires precision and control and can result in beautiful patterns and textures in the finished product. Forge welding has been used for centuries by blacksmiths and metalworkers to create unique objects that are both functional and aesthetically pleasing.

Overall, forge welding is an impressive and versatile technique that can be used by professionals and amateurs alike to create unique and durable objects. With its rich history and endless possibilities, forge welding is definitely worth exploring as an option for anyone interested in metalworking.

What Materials Are Ideal for Forge Welding Without a Welder?

With the right materials and technique, anyone can create beautiful patterns and textures in their metalwork without the use of a welder. However, it’s important to note that not all materials are ideal for this technique.

One material that’s perfect for forge welding without a welder is canister damascus powder. This unique steel is made by layering different types of metal powder, such as iron and nickel, inside a canister and heating it in a forge.

The high temperatures cause the metals to fuse together, creating a stunning pattern that’s both beautiful and durable. Plus, canister damascus powder contains flux, which helps prevent oxidation and contamination during the welding process.

Mild steel is another great choice for forge welding without a welder. This low-carbon steel is easy to work with and perfect for beginners.

To forge weld mild steel, you’ll need to clean the surfaces thoroughly and heat them to a high temperature before hammering them together. It’s crucial to maintain the proper temperature throughout the welding process to ensure a strong bond between the two pieces of metal.

If you’re looking for a more traditional option, wrought iron is an excellent choice for forge welding without a welder. This iron alloy contains very little carbon and is known for its malleability and ductility.

It can be forged at lower temperatures than other metals, making it easier to work with. However, finding wrought iron in modern times can be difficult so it may not be the most practical choice for everyone.

In conclusion, forge welding without a welder requires skill, experience, specialized tools such as a forge or furnace, anvil, and hammer but can result in stunning finished products. Canister damascus powder, mild steel, and wrought iron are all excellent choices for those looking to try this technique without a welder.

But remember to practice proper safety precautions and maintain the correct temperature throughout the welding process to ensure a strong bond between the two pieces of metal.

How to Prepare the Metal Pieces for Forge Welding

With the right preparation, you can achieve strong, durable welds without the need for expensive equipment. In this article, we’ll explore five essential steps to prepare your metal pieces for forge welding without a welder.

Choose the Right Metal

Selecting the right type of metal is crucial for successful forge welding. Canister Damascus materials are an excellent choice as they’re made up of layers of steel that can be easily forged together. High carbon steel and nickel are also popular options.

Clean Thoroughly

Before beginning the welding process, it’s important to remove any impurities or contaminants from your metal pieces. Use a wire brush or sandpaper to clean them thoroughly, and wear gloves to avoid transferring oils or dirt from your hands onto the metal.

Cut Appropriately

Use a hacksaw or angle grinder to cut your metal into appropriately sized pieces for your project. Ensure that the edges are straight and smooth for a perfect fit during welding.

Heat Up Your Metal

To make your metal more malleable for forging and remove any remaining impurities, heat it up in a forge or with a propane torch. However, be cautious not to overheat it, as this can damage the metal.

Apply Flux

Before beginning the welding process, apply flux to the metal for stronger bonding between pieces during welding. A popular choice for canister Damascus is borax powder mixed with water.

By following these five essential steps, you’ll be well on your way to successful forge welding without a welder.

How to Heat the Metal Pieces in the Forge

Not to worry. You can still achieve quality results by following proper technique and using high-quality equipment. The first step is to heat the metal pieces in a forge. This process is vital because it softens the metal, making it easier to manipulate and join together. So, how do you heat the metal pieces in a forge without a welder? Let’s find out.

Choose the Right Type of Forge

The first step in heating metal pieces in a forge is to choose the right type of forge for your needs. There are different types of forges available, such as coal forges, gas forges, and propane forges. Each type has its advantages and disadvantages, so choose one that suits your needs and budget.

Prepare the Forge

Once you have chosen the type of forge you want to use, it’s time to prepare it for heating the metal. Start by cleaning the inside of the forge to remove any debris or ash that may interfere with the heating process. Use a wire brush or scraper to remove any rust or dirt from the walls and floor of the forge. Then load the metal pieces into the forge, arranging them properly to ensure they heat up evenly.

Heat the Metal Pieces

Now it’s time to start heating up those metal pieces. Turn on your forge and let it heat up until it reaches the desired temperature. The temperature needed will depend on the type of metal you are working with and what you plan to do with it. Generally, a forge temperature of around 2000°F is required for most metals.

Monitor the Metal Pieces

As you heat up the metal pieces, keep an eye on them at all times. It’s essential to prevent any areas from overheating or underheating, which can lead to problems with forging later on. To ensure even heating, use tongs or pliers to rotate the metal pieces periodically during the heating process.

Work Quickly and Efficiently

Once the metal has reached the desired temperature, it can be removed from the forge and placed onto an anvil or other forging surface. It’s crucial to work quickly and efficiently at this point to complete the forge welding process before the metal cools down too much. The hotter the metal, the easier it is to shape and join together.

So, heating metal pieces in a forge is an essential step in forge welding without a welder.

By choosing the right type of forge, preparing it properly, loading the metal pieces correctly, monitoring them carefully as they heat up, and working quickly and efficiently, you’ll be able to heat your metal pieces safely and effectively for successful forge welding without a welder.

Hammering the Metal Pieces Together on an Anvil

Hammering the metal pieces together on an anvil is the final step in forge welding without a welder. And with a little patience and practice, even beginners can create beautiful, functional pieces of metalwork.

Once the two metal pieces have been heated, fluxed, and placed together in the canister, it’s time to begin the hammering process. Start by removing the canister from the forge and placing it on the anvil.

Then, using a hammer, strike the canister firmly to break away the outer layer of clay and reveal the welded billet inside. After that, use a chisel or saw to carefully cut away any excess metal around the edges of the billet.

Once it’s cleaned up, it’s time to start hammering.

Begin with light taps and gradually work your way around the edges of the billet to ensure it remains even in thickness.

As you continue hammering, gradually increase the force of your blows until you are striking the metal with a solid, consistent rhythm. Take breaks as needed to allow yourself and your equipment to cool down.

Remember not to rush the process – forging welded metal takes time and patience. It’s an exciting feeling when the billet is fully welded together into a single piece of metal.

Monitoring Heat During the Process

In this section, we’ll be discussing the crucial role of monitoring heat during the process. When it comes to forge welding, heating the metals correctly is key.

Overheating or underheating can lead to disastrous consequences, such as brittle metal or a weak bond. That’s why monitoring the temperature throughout the process is essential.

One effective method for monitoring heat is using a magnet. As the metal heats up, it loses its magnetic properties.

Simply hold a magnet near the metal, and you’ll know when it’s reached the optimal temperature for forge welding. It’s like having a secret superpower.

Another method is by using a color chart. As the metal heats up, it changes color, offering visual cues that indicate different temperatures.

This makes it easy to monitor and adjust accordingly. It’s like an artist’s palette, but with fire.

Of course, safety should always come first. Be sure to wear gloves and protective eyewear to shield yourself from hot metal shards and sparks.

By monitoring heat during the process, you can ensure that your forge welding without a welder will be a success and produce a strong bond between the metals.

lmQbQ50kh7o” >

Conclusion

In conclusion, forge welding without a welder is an ancient technique that requires patience, skill, and the right tools.

By heating metal pieces to their melting point and hammering them together, you can fuse them into a single piece of metal without using filler material. To successfully forge weld, you need access to specialized tools such as a forge or furnace, anvil, and hammer.

Canister damascus powder, mild steel, and wrought iron are all excellent choices for those looking to try this technique without a welder. However, it’s important to remember that not all materials are suitable for this method.

When it comes to safety precautions and temperature control during the welding process, you must be careful. Proper heat monitoring is essential for a strong bond between the two pieces of metal.

With its rich history and endless possibilities, forge welding is definitely worth exploring as an option for anyone interested in metalworking.