Are you looking for an effective way to clean stainless steel after welding? Welding stainless steel is a cost-effective way to produce strong, durable buildings, but it’s impossible to get the final product looking its best without proper post-weld cleaning.

In this blog post, we’ll cover everything you need to know about cleaning stainless steel after welding. We’ll discuss the tools and equipment required, as well as the steps involved in getting your welds looking their best.

Plus, you’ll learn about different types of cleaners and tips and tricks for removing stubborn spots from your welds. We’ll also explain why shielding your stainless steel after washing is so important for achieving a beautiful finish that lasts for years.

So, grab your supplies and let’s get started.

Removing Surface Debris and Contaminants

Contents

- 1 Removing Surface Debris and Contaminants

- 2 Cleaning with Detergent and Water

- 3 Light Discoloration or Oxidation

- 4 Severe Discoloration or Rust

- 5 Acidic Solutions for Cleaning Stainless Steel After Welding

- 6 Citric Acid Solution for Cleaning Stainless Steel After Welding

- 7 Other Solutions for Cleaning Stainless Steel After Welding

- 8 Tips and Tricks for Cleaning Stainless Steel After Welding

- 9 Conclusion

Welding stainless steel is a cost-effective way to create strong, durable structures.

However, if the metal isn’t adequately cleaned after welding, it can corrode or discolor over time. Fortunately, there are some simple steps you can take to ensure that your stainless steel looks its best.

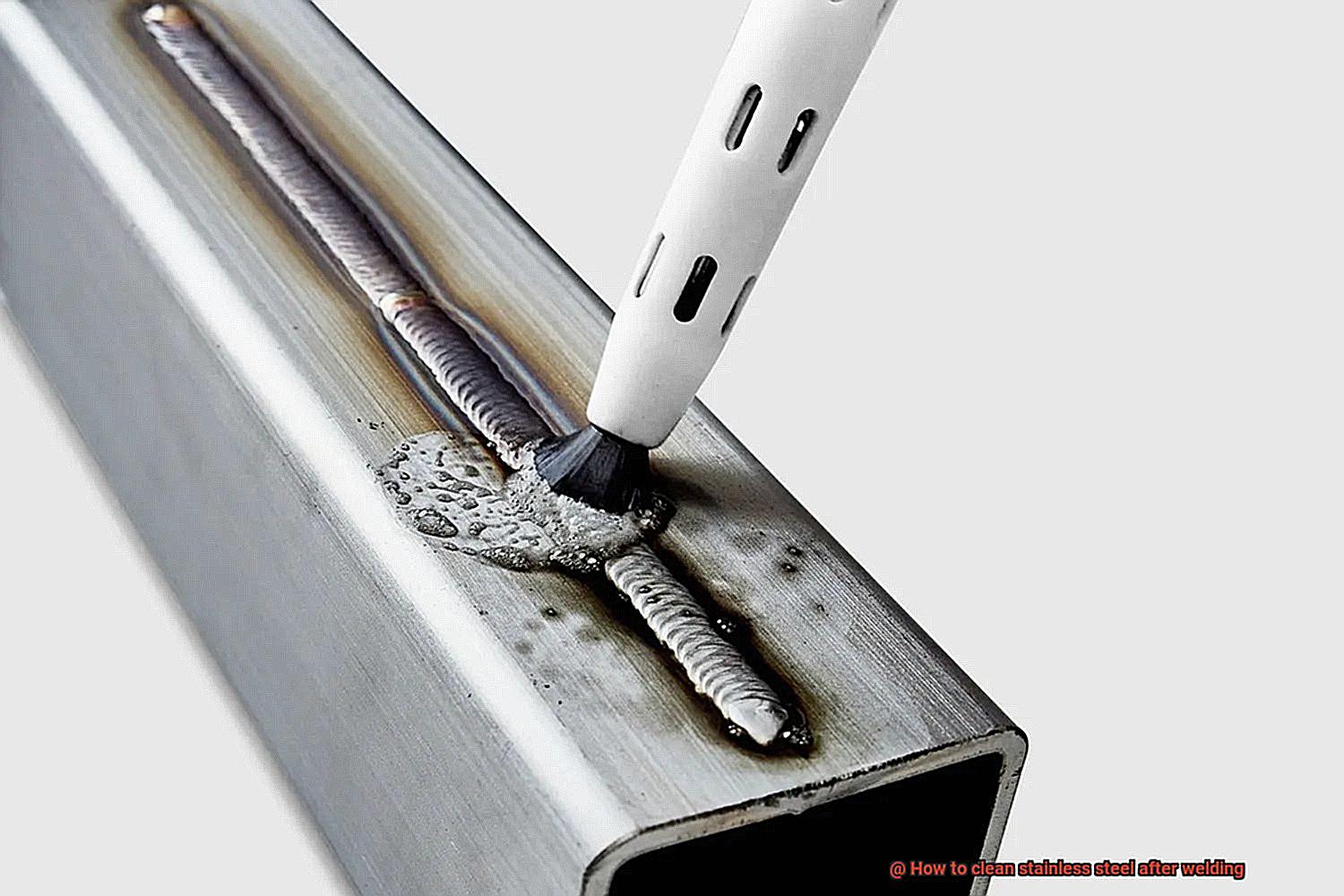

The first step in restoring stainless steel is to remove any surface debris and contaminants. This can be done with a wire brush or abrasive pad specifically designed for stainless steel, as using anything too aggressive or using the wrong type of brush can cause scratches or damage to the metal.

Once the initial scrubbing is done, it’s important to thoroughly clean the surface using a degreaser or solvent cleaner. This will help to remove any grease or oil that may be present on the metal, which can attract dirt and other particles.

Make sure to follow the manufacturer’s instructions when using any chemical cleaners, and always wear appropriate protective gear. For light discoloration or oxidation, you can use a paste made of equal parts baking soda and water and scrub it into the surface with a soft cloth or brush.

For more severe discolorations or rust spots, try mixing equal parts white vinegar and water and then rinsing with water for several minutes. If that doesn’t work, you may also try citric acid for an acidic solution.

Cleaning with Detergent and Water

Welding stainless steel can create strong and beautiful structures, but it’s also important to clean it properly afterwards to preserve its original appearance and prevent any rust or discoloration.

An easy and cost-effective way to restore the metal’s shine is by cleaning stainless steel with detergent and water. Begin by ensuring the surface is free of debris, dust, or leftover welding materials.

Mix a mild detergent with warm water in a bucket or sink. Dip a soft cloth or sponge into the soapy solution and gently scrub the stainless steel surface, paying attention to all corners and edges.

Avoid using any abrasive materials like steel wool or brushes as these can leave scratches or cause damage to the surface. To remove any soap residue, rinse the surface with clean water or wipe it down with a damp cloth.

It’s important to note that some detergents may react with stainless steel and cause discoloration or damage, so always test a small area before cleaning the entire surface and use only mild detergents for best results.

Light Discoloration or Oxidation

Keeping your stainless steel welds looking their best is easy with a few simple steps and the right cleaner.

After welding, light discoloration or oxidation can occur due to the heat generated during the process, but this can be quickly remedied with some basic cleaning techniques. Start by using a soft-bristled brush to remove any surface debris such as welding flux or splatter.

Then, apply a mild detergent solution and scrub the surface with a nylon brush to get rid of any further contamination. Rinse off the soap with clean water and let it dry naturally.

If you still notice discoloration or oxidation, you may need to use an acidic cleaner specifically designed for removing these stains. Citric acid or phosphoric acid are two popular options, but be sure to dilute them according to the manufacturer’s instructions before use.

Apply the solution to the surface with a soft-bristled brush and let it sit for a few minutes before scrubbing gently and rinsing off with fresh water. Remember to always wear protective gloves when handling acidic cleaners.

In some cases, one cleaning treatment may not be enough to completely remove discoloration or oxidation from stainless steel after welding. If this is so, you may need to repeat the cleaning procedure multiple times or try different cleaners until you find one that works for you.

Just make sure not to be too aggressive when scrubbing as this can damage your welds and alter their appearance.

Severe Discoloration or Rust

First and foremost, it’s essential to assess the extent of the discoloration or rust. If it’s minor, a simple scrub with a nylon pad and warm soapy water will do the trick.

However, if it’s more severe, you may need to use an acid cleaner like nitric acid. When using an acid cleaner, safety must be a priority.

Wear gloves and protective eyewear at all times and dilute the acid with water to a ratio of 1:10 (one part of acid to ten parts of water). Apply the paste to the metal surface using a scrubber or brush and leave it for several minutes before rinsing off with water.

Cleaning stainless steel welds is achievable with these steps in mind.

Acidic Solutions for Cleaning Stainless Steel After Welding

Welding stainless steel can be a great way to join two pieces together, but keeping the weld clean and shiny can be a challenge.

Fortunately, acidic solutions are an effective way to clean stainless steel after welding. Nitric acid and citric acid are the most commonly used options, but there are pros and cons associated with each of them.

Nitric acid is a powerful and highly corrosive chemical, so it should be handled with care and proper safety precautions should always be taken when using it. On the plus side, nitric acid efficiently breaks down the oxide layer that forms over the stainless steel surface during welding, leaving behind a cleaner and shinier finish.

Citric acid is less corrosive than nitric acid, making it a safer alternative for cleaning stainless steel after welding. It’s also an environmentally friendly option because it is biodegradable.

When using acidic solutions for cleaning your stainless steel after welding, make sure you follow the manufacturer’s instructions carefully.

Citric Acid Solution for Cleaning Stainless Steel After Welding

Welding stainless steel can be a tricky task, but thankfully there is an easy and safe solution for cleaning it afterwards: citric acid.

This natural and eco-friendly alternative to harsher chemicals not only removes unwanted residue without damaging the metal, but is also safe to use and dispose of. Here’s how it works:

First, create a 10% citric acid solution with 90% water. To maximize its cleaning power, heat the mixture to around 150°F to 170°F.

Then, apply a light coat of the solution using a brush, cloth, or spray bottle and let it sit for 15-30 minutes depending on the severity of the stain or discoloration.

Finally, rinse off any remaining citric acid residue with water and dry the stainless steel with a clean cloth.

Other Solutions for Cleaning Stainless Steel After Welding

Welding stainless steel can be a tricky job, but don’t worry – there are plenty of solutions for cleaning it afterwards.

From alkaline cleaners to acid cleaners, and even household items like vinegar and lemon juice, you have plenty of options to make your stainless steel welds look their best. Alkaline cleaners are great for removing oils, fats, or greases from the metal’s surface.

Acid cleaners are particularly effective at removing rust and scale, but should be used with caution as they can also attack the metal if not properly applied. Vinegar and lemon juice are natural solutions that can break down rust and other stains without damaging the surface of the metal.

And if you’re looking for something more specialized, there are various stainless steel after welding cleaning kits available on the market.

Tips and Tricks for Cleaning Stainless Steel After Welding

Cleaning stainless steel after welding is an essential step in ensuring that your welds are strong and look great for years to come. Whether you’re a professional welder or a hobbyist, these tips and tricks will help you get the most out of your stainless steel welding projects.

Removing Excess Weld Material

Start by grinding or wire brushing any excess weld material. This will make sure the stainless steel’s surface is clean before applying any cleaners.

Cleaning with Stainless Steel Specific Cleaners

To remove any contaminants such as oil, sand, and grime, use a stainless steel specific cleaner. These cleaners are specially formulated not to damage stainless steel’s surface, so be sure to read the instructions carefully before using them.

Paying Attention To Welding Technique

When washing stainless steel after welding, it is also important to pay attention to the type of welding that was used. For example, if TIG welding was used, additional heat tint or discoloration may have to be removed in order to maintain a professional finish.

Alkaline Cleaning Procedure

For more stubborn stains or discoloration, an alkaline cleaning procedure may be necessary. This treatment uses a mild alkaline solution that can effectively eliminate rust and other forms of staining. To prevent any grime from remaining on the surface, be sure to rinse the surface with warm water after applying the treatment.

NG5_sbRtWDk” >

Conclusion

Welding stainless steel is a great way to create strong, long-lasting structures.

However, it’s impossible to get the best finish without proper post-weld cleaning. In this blog article, we’ve covered everything you need to know about cleaning stainless steel after welding.

From the tools and equipment you’ll need to the steps involved in getting your welds looking their best – you now have all the information you need for a successful clean-up. We discussed various types of cleaners, tips and tricks for removing stubborn spots from your welds, as well as why shielding your stainless steel after washing is so important for achieving an amazing finish that will last for years.

If using mild detergent and water or an acidic cleaner such as citric acid or nitric acid, remember to wear protective gear and follow the manufacturer’s guidelines when using chemical cleaners.