Did you know that welding oxygen cylinders have an expiration date just like food and medicine? It’s true. As a welder, it’s crucial to pay attention to the expiry date of your welding oxygen cylinder to prevent accidents or mishaps. Oxygen cylinders play a vital role in welding, and if they’re expired, they can cause severe harm to both you and your surroundings.

But how do you check the expiry date of your welding oxygen cylinder? It’s a question every welder must know the answer to. In this blog post, we’ll guide you on how to check the expiry date of your welding oxygen cylinder using different methods such as visual inspection, cylinder stamp, and cylinder neck ring.

The expiry date is significant because it ensures that the gas inside the cylinder is safe for use. Ignoring it can lead to dangerous consequences. We’ll explain why you should never ignore the expiry date and emphasize its importance.

Whether you’re a professional welder or DIY enthusiast, our blog post will equip you with essential knowledge and skills to check your welding oxygen cylinder’s expiry date for safety reasons. So keep reading to learn how to check your welding oxygen cylinder’s expiry date and stay safe while working.

What is an Oxygen Cylinder Expiry Date?

Contents

- 1 What is an Oxygen Cylinder Expiry Date?

- 2 Factors that Affect the Lifespan of a Welding Oxygen Cylinder

- 3 How to Identify the Expiry Date of a Welding Oxygen Cylinder

- 4 Checking for Stamped Markings on the Cylinder

- 5 Inspecting the Physical Condition of the Cylinder

- 6 Adhering to Regulations on Cylinder Expiry Dates

- 7 Conclusion

Oxygen cylinders are essential pressurized containers that hold compressed oxygen gas, used for industrial and medical purposes. However, these cylinders have a limited lifespan and must be checked regularly to ensure their safety.

The expiry date of an oxygen cylinder is the date after which it’s no longer safe to use. This date is usually stamped on the cylinder’s shoulder or neck and is indicated by a month and year. It’s essential to note that the expiry date is different from the hydrostatic test date, which checks the cylinder’s integrity.

While it may be tempting to overlook expiry dates, using an expired oxygen cylinder can have severe consequences. The cylinder may leak or rupture, causing harm to those nearby. Additionally, expired cylinders may not contain enough oxygen to meet the user’s needs or contain impurities that could be harmful when inhaled.

To avoid such risks, it’s crucial to check the expiry date of oxygen cylinders before use. Whether you’re in the medical or industrial field, using an expired cylinder can lead to costly delays, accidents, or even life-threatening situations.

Proper storage and handling of oxygen cylinders can also help extend their lifespan and ensure their safety. They should be stored in a cool, dry place away from heat sources and flammable materials, and secured in an upright position to prevent any damage to the valve or regulator.

In conclusion, taking the time to check an oxygen cylinder’s expiry date can ensure its safety and prevent catastrophic outcomes. So make sure to regularly inspect your cylinders for any stamped markings and physical damage.

Factors that Affect the Lifespan of a Welding Oxygen Cylinder

In this article, we will explore the various factors that can affect the lifespan of a welding oxygen cylinder and how to prolong their life.

Firstly, the quality of the cylinder itself is crucial. Poor quality cylinders may have manufacturing defects or be made with subpar materials, leading to faster deterioration and potential safety hazards. It is essential to purchase cylinders from reputable manufacturers and suppliers to ensure the highest quality and safety.

Secondly, proper storage and maintenance can significantly impact the lifespan of a welding oxygen cylinder. Cylinders should be stored in cool, dry areas away from direct sunlight and sources of heat. They should also be kept away from flammable substances and chemicals to avoid any potential hazards. Regular maintenance and inspections are also necessary to keep cylinders in optimal condition. Conducting a visual inspection regularly to check for any signs of damage or corrosion is critical.

The valve and regulator should also be inspected for leaks or damage, and any identified issues should be addressed promptly. By performing regular maintenance and inspections, you can ensure that your welding oxygen cylinder is in optimal condition and avoid potential safety hazards.

Moreover, the frequency of use and type of welding being performed can also affect the lifespan of a welding oxygen cylinder. Frequent usage wears out cylinders faster than infrequent usage. Additionally, certain types of welding processes may require more oxygen, putting more strain on the cylinder. Therefore, it is essential to monitor your usage and choose the appropriate cylinder size for your specific needs.

In conclusion, welding oxygen cylinders are critical tools that require proper care and attention to ensure their longevity. While the expiration date is an important factor to consider, it is not the only factor that affects their lifespan. Proper storage, maintenance, and usage can all contribute to prolonging the life of these essential tools. Remember, a well-kept cylinder is not only safer but also saves money in replacement costs.

How to Identify the Expiry Date of a Welding Oxygen Cylinder

As a welding professional, you know that safety comes first in your line of work. And one of the essential aspects of ensuring your safety is identifying the expiry date of your welding oxygen cylinders. It’s crucial to know when your cylinders are due for testing to avoid any safety hazards that may arise from using expired or damaged cylinders. Here are five subtopics to help you identify the expiry date of a welding oxygen cylinder.

Stamped Markings

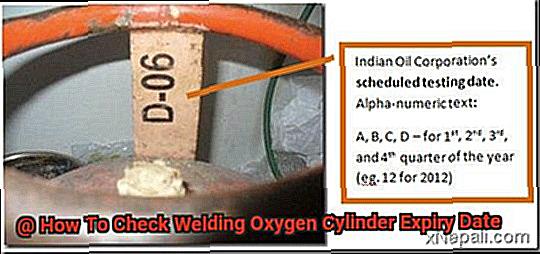

The first step in identifying the expiry date of a welding oxygen cylinder is locating the stamped markings on the cylinder’s shoulder or neck. You’ll see a four-digit number that represents the month and year of manufacture, usually stamped with a circle or oval around it. This marking is crucial because it helps calculate the expiry date of your cylinder.

Design Life

Once you have located the stamped markings, check the cylinder label for information on its design life. The label should also include the manufacturer’s name, serial number, and other essential information. The design life can vary from 5 to 10 years depending on the type and size of the cylinder.

Calculation

After you have both pieces of information, you can calculate the expiry date of the cylinder. Add the design life to the month and year of manufacture to determine when the cylinder will expire. However, it’s always best to double-check with the manufacturer or a certified gas supplier to ensure accuracy.

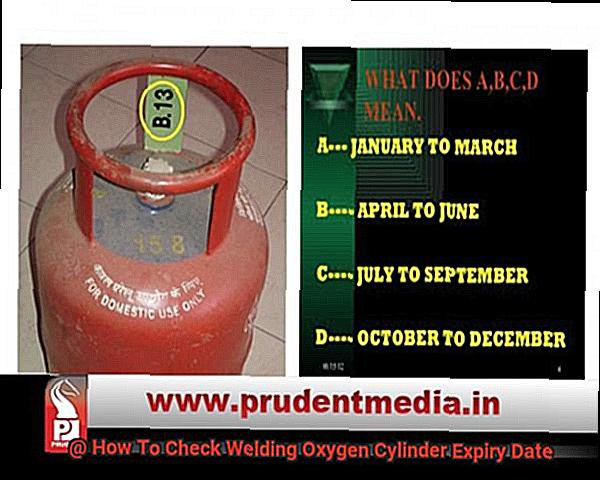

Color-Coded System

Another way to identify the expiry date of a welding oxygen cylinder is through a color-coded system. This system involves painting a band around the neck of the cylinder with a specific color, indicating when it was last tested. Each color represents a particular year in which the cylinder was last tested. However, this color-coded system may vary depending on your location, so make sure to consult with your local welding supplier or regulator.

Regular Inspection

Lastly, it’s essential to inspect your cylinder’s physical condition regularly. Any signs of damage, such as dents or rust, can compromise the cylinder’s integrity and make it unsafe for welding operations. By inspecting your cylinder regularly, you can ensure that it’s in good condition and within its testing period.

In conclusion, identifying the expiry date of a welding oxygen cylinder is crucial for your safety. By looking for stamped markings, checking the design life, calculating the expiry date, using a color-coded system, and inspecting your cylinder regularly, you can ensure that you’re using safe and reliable cylinders. Remember to always consult with your local supplier or regulator if you have any doubts or questions about identifying expiry dates.

Checking for Stamped Markings on the Cylinder

As a welding professional, safety should be your top priority. That’s why it’s crucial to check for stamped markings on your welding oxygen cylinder before using it. These markings provide essential information about the cylinder’s manufacturing date, its last hydrostatic test date, and its expiry date.

To check for stamped markings, take a look at the shoulder or neck of the cylinder. You’ll spot a set of numbers and letters that represent crucial details about the cylinder’s safety.

The manufacturing date is indicated by four digits that show the month and year of manufacture. For example, “0415” would mean that the cylinder was manufactured in April 2015.

The last hydrostatic test date is another critical piece of information stamped onto the cylinder. This test ensures that the cylinder is still safe to use and has not weakened over time. The hydrostatic test date is usually represented by four digits or letters.

Most importantly, the expiry date is stamped onto the cylinder and tells you when it should be taken out of service. The expiry date is typically represented by a month and year format. Once a cylinder has expired, it should be taken out of service immediately to avoid any accidents or injuries.

By checking for stamped markings on your welding oxygen cylinder, you can ensure your safety and avoid any potential hazards. Remember, using an expired cylinder can be dangerous and lead to accidents or injuries.

Inspecting the Physical Condition of the Cylinder

Before a knight goes into battle, his armor needs to be checked for any cracks or dents that could compromise his safety. Similarly, inspecting the physical condition of a welding oxygen cylinder is crucial to ensure safety and protect yourself from potential harm.

To start, examine the cylinder’s exterior for any visible signs of damage, such as dents, corrosion, or cracks. These seemingly small issues can compromise the integrity of the cylinder and make it unsafe to use. Think of it like a chink in a knight’s armor – it may seem minor, but it could have serious consequences.

Next, move on to the valve. A leaking valve can cause a dangerous buildup of pressure in the cylinder, resulting in explosions or fires. Check that the valve is not damaged or leaking and that the valve stem is not bent or broken, which could prevent proper attachment of regulators and hoses.

It is also important to check the label on the cylinder to ensure that it matches the gas inside. Using the wrong type of gas can result in serious injury or even death. The label should also indicate when the cylinder was last inspected and serviced, which can help determine if it is safe for use.

Remember, if any issues are found during inspection, do not use the cylinder and have it inspected by a professional before attempting to use it again. Regular inspections and maintenance can ensure the safety and longevity of welding oxygen cylinders.

Adhering to Regulations on Cylinder Expiry Dates

To ensure the safety of welders, DOT mandates that oxygen cylinders must undergo visual inspections every five years and hydrostatic testing every ten years. These safety regulations are not mere formalities; they are in place to safeguard workers from catastrophic consequences such as explosions, fires, or even death.

To determine the expiry date of your welding oxygen cylinder and ensure its safety, locate the stamped markings on the cylinder. These markings usually include the manufacturer’s name, serial number, and date of manufacture. It is essential to note the date of manufacture as it determines when the cylinder is due for its first visual inspection.

Calculating the expiry date is simple – add five years to the date of the last visual inspection. For instance, if your last visual inspection was conducted on January 1st, 2020, then your cylinder’s expiry date would be January 1st, 202However, it’s important to remember that this is not an exact science and can vary based on how well you handle and store your cylinder.

By adhering to regulations on cylinder expiry dates and conducting regular visual inspections and hydrostatic testing, you can ensure that your cylinders are safe for use. It is also crucial to store cylinders correctly in a well-ventilated area away from heat sources and combustible materials.

Ho76wh5cnK4″ >

Conclusion

To sum up, it is imperative to check the expiry date of your welding oxygen cylinder to guarantee safety in the workplace. An expired cylinder can pose a significant risk and must be taken out of service immediately. Regular inspections and adherence to regulations on visual checks and hydrostatic testing are vital for maintaining the longevity of your cylinder.

There are several ways to identify the expiry date, such as stamped markings, design life, calculation, color-coded systems, and regular inspections. Proper storage is also crucial to ensure that cylinders remain in good condition. Always keep them in a cool, dry place away from heat sources and combustible materials.

Neglecting to check for an oxygen cylinder’s expiry date can lead to dangerous consequences like leaks or ruptures that can cause severe harm. Therefore, it is essential to take the time to inspect for stamped markings and physical damage regularly.