Are you in need of a quick and easy solution for fixing your broken or damaged stainless steel parts? Look no further than JB Weld. This versatile epoxy has been recommended time and time again, but the question on everyone’s mind is whether it truly works on stainless steel.

Before diving into your next project, it’s important to understand the properties of stainless steel and how they differ from other metals. Additionally, evaluating which type of JB Weld product is compatible with stainless steel is crucial. Lastly, considering the specific circumstances of your project will ensure that you choose the right product for the job.

In this article, we’ll explore whether JB Weld works on stainless steel in depth. We’ll cover the science behind JB Weld’s bonding capabilities, examine different types of stainless steel and their unique properties, and provide best practices for using JB Weld on your next project. By the end of this article, you’ll have a better understanding of whether JB Weld is suitable for your particular stainless steel repair project. So let’s dive in together and explore the world of JB Weld on stainless steel.

What is JB Weld?

Contents

For over 50 years, JB Weld has been a go-to adhesive for professionals and DIYers alike. This two-part epoxy is known for its strength, durability, and versatility, making it an excellent choice for various applications.

JB Weld consists of a resin and a hardener that, when mixed together in equal parts, chemically bond to create an impressively strong permanent bond. Not only can JB Weld bond together metals, plastics, ceramics, and wood with ease, but it is also resistant to water, chemicals, and high temperatures.

One of the main reasons for JB Weld’s popularity is its simplicity of use. Mixing the two components together is easy and can be applied to the surfaces you want to bond. Once cured within 4-6 hours, JB Weld can be sanded, drilled, and painted to blend seamlessly into the surrounding surface.

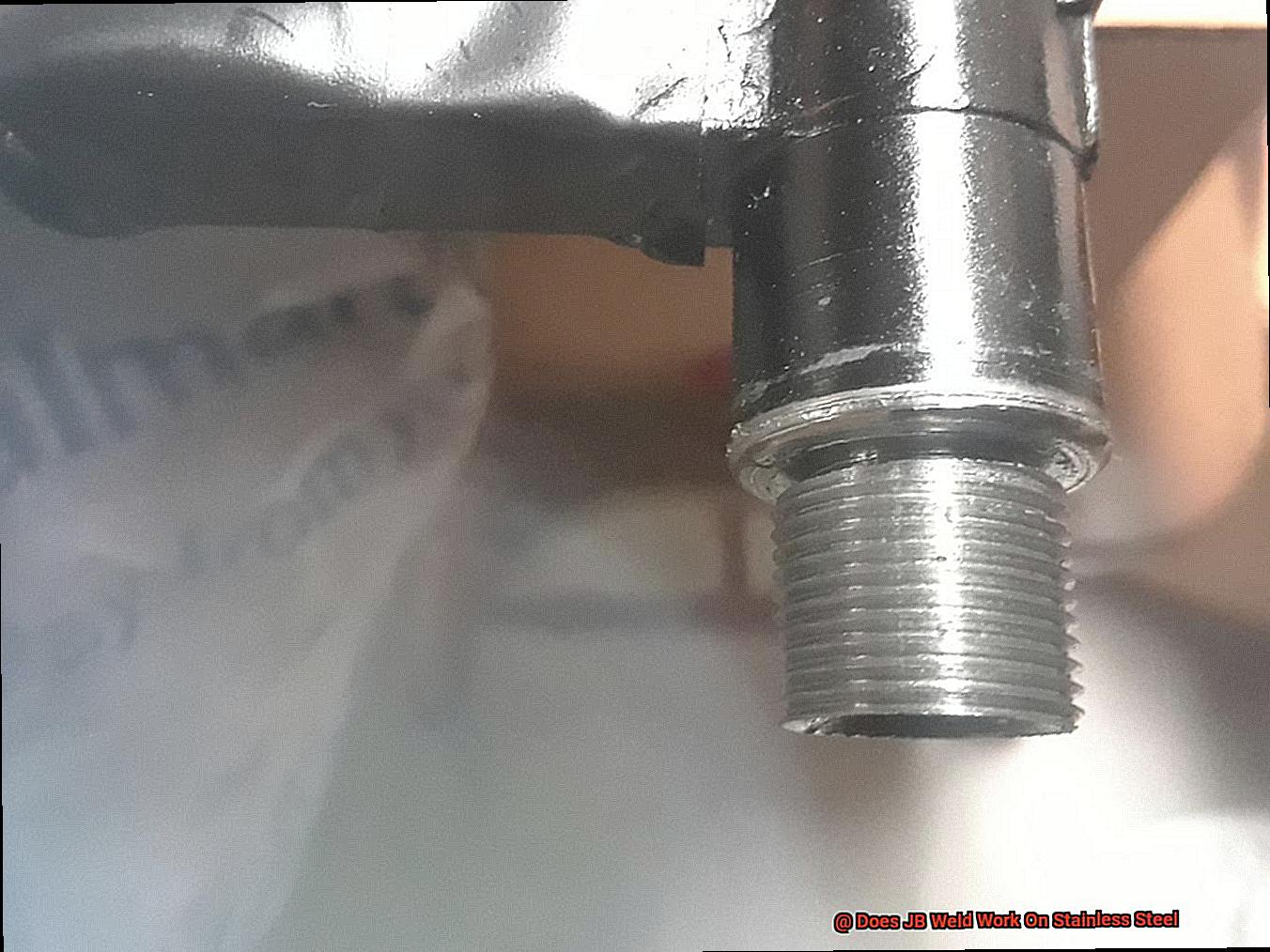

But what about stainless steel? Yes. JB Weld works on stainless steel too. However, not all grades of stainless steel are created equal. Some types may be more challenging to bond due to their composition and surface characteristics.

If you’re looking to bond stainless steel with JB Weld, it’s crucial to clean the surface meticulously before applying the adhesive. Use a degreaser or rubbing alcohol to remove any dirt or grease and sand the surface with fine-grit sandpaper for better adhesion. When bonding larger pieces together, it’s recommended to use clamps or other tools to hold the surfaces in place while curing.

Although JB Weld can withstand high temperatures and pressure, it may not be suitable for applications where high impact or vibration is expected. In such cases, welding or brazing may be a better option.

Overall, JB Weld is an incredibly reliable and versatile adhesive that continues to be trusted by professionals and DIYers alike. Its ability to bond different materials together and withstand harsh conditions makes it an ideal choice for many diverse applications.

Can JB Weld be Used on Stainless Steel?

Look no further than JB Weld. This two-part epoxy adhesive is a popular choice among DIY enthusiasts and professionals due to its strength and versatility. But before you dive in, it’s important to know that not all formulations of JB Weld are suitable for use on stainless steel. So which one should you choose?

First, prepare the surface properly. Clean the surface with a solvent like acetone or rubbing alcohol to remove any oil, grease, or other contaminants that could interfere with the bonding process. Once the surface is clean and dry, rough it up with sandpaper or a wire brush to increase the surface area for bonding and improve adhesion.

When it comes to selecting the right formulation of JB Weld for your stainless steel project, consider the type of stainless steel you’ll be bonding and the intended application. Some formulations may work better than others depending on these factors.

With proper preparation and the right formulation, JB Weld can provide a strong and durable bond on stainless steel surfaces. So go ahead and tackle that project with confidence. Just remember to select the appropriate formulation and prepare the surface correctly.

Preparing the Surface for Bonding

Well, look no further. Preparing the surface for bonding is a crucial step that can make all the difference.

Step 1: The Clean Sweep

The first step in preparing the surface is to clean it thoroughly. A clean surface is essential for a successful bond. Ensure the surface of the stainless steel is dry, free of any oils, debris, or rust. We recommend using acetone to clean the surface thoroughly, as it guarantees no contaminants are left behind.

Step 2: Roughen It Up

After cleaning, it’s necessary to roughen up the surface for a better mechanical bond with JB Weld. To achieve this, sand the surface with coarse grit sandpaper (80-grit) until it’s no longer shiny. This process creates a “tooth” that JB Weld can stick to and ensures a permanent bond.

Step 3: Keep It Cool

Temperature also plays a role in achieving optimal bonding results. Make sure the surface is at room temperature before applying JB Weld. If it’s too cold, JB Weld may take longer to cure properly. Conversely, if it’s too hot, JB Weld may cure too quickly and not bond effectively.

Preparing the surface for bonding is critical in ensuring that JB Weld works effectively on stainless steel. By cleaning the surface thoroughly using acetone, roughening it up with coarse grit sandpaper, and ensuring that the surface is at room temperature before applying JB Weld, you’re guaranteed a strong and long-lasting bond between the stainless steel and JB Weld.

Applying JB Weld to Stainless Steel

JB Weld is a popular choice, but it’s important to understand the proper techniques for applying this epoxy to ensure a strong and secure bond. With that said, let’s dive into what you need to know about applying JB Weld to stainless steel.

First and foremost, it’s essential to note that JB Weld is not a welding technique. It’s an epoxy that can be used to bond two pieces of metal together. While it can be effective for some applications, it may not be the best choice for others.

To begin, you need to clean the surface of the metal thoroughly. Any grease, oil or other contaminants can prevent the epoxy from bonding correctly. Use a degreasing agent or acetone to clean the surface and ensure it’s completely dry before proceeding.

Next, mix the JB Weld according to the manufacturer’s instructions. Ensure that you mix it thoroughly as any unmixed areas can weaken the bond.

When it comes to applying JB Weld to stainless steel, use a thin layer. This will help guarantee that the bond is strong and secure. You can use a brush or spatula to apply the epoxy, but you must work quickly as it will start to harden within minutes.

After applying the JB Weld, let it cure for at least 24 hours before using or handling the metal. This will give the epoxy enough time to fully harden and create a robust bond.

It’s important to remember that while JB Weld can be effective for bonding stainless steel, it has its limitations. Therefore, it’s crucial to follow proper application techniques for best results.

Advantages and Disadvantages of Using JB Weld on Stainless Steel

One of the biggest benefits of using JB Weld on stainless steel is its strong bond. This two-part epoxy has a reputation for creating a robust and durable connection on many different materials, including stainless steel.

Whether you are repairing a broken machine part or creating a DIY project, JB Weld provides a reliable hold. Plus, applying JB Weld to stainless steel is quick and easy, requiring minimal preparation and equipment. That means you can get the job done faster and save money in the process.

Another advantage of JB Weld is its cost-effectiveness. Compared to other welding methods, JB Weld is relatively inexpensive and requires only basic equipment. That makes it an excellent option for those on a budget or those who don’t have access to specialized welding tools.

And because JB Weld is versatile, it can be used on a variety of surfaces, including stainless steel. It even repairs cracks and holes in stainless steel, making it an efficient solution to many types of damage.

However, there are some downsides to consider as well. Firstly, JB Weld may not hold up well under extreme temperatures, which limits its suitability for certain applications.

Additionally, while JB Weld is strong, it can also be brittle, meaning that it may not flex or bend as well as other welding methods. So if your project requires flexibility or movement, you may want to explore other options.

Another disadvantage of JB Weld is its long curing time. It can take up to 24 hours to fully cure, which may not be practical for certain projects that require immediate use. And finally, the appearance of JB Weld may not be as aesthetically pleasing as other welding methods. While it provides a strong bond, the finish can look rough or uneven, which could be an issue for some users.

Alternatives to JB Weld for Bonding Stainless Steel

When it comes to bonding stainless steel, JB Weld is a trusted solution for many people. But did you know there are other options available that may be better suited to your specific application?

Epoxy adhesive is a popular alternative that boasts strong bonding capabilities and resistance to chemicals and water. It can even fill gaps and cracks in the material being bonded, making it ideal for projects requiring durability.

Superglue, or cyanoacrylate glue, is another option that dries quickly and bonds stainless steel effectively. However, it may not hold up as well under stress as other options like epoxy or welding.

Welding is a popular choice for those seeking a strong and permanent bond between metals. While it requires specialized equipment and skills, welding can also repair damaged or broken stainless steel parts.

Mechanical fasteners like screws, bolts, and rivets offer another option for attaching stainless steel parts together. This method allows for easy disassembly and reassembly of parts if needed. However, it may not provide as strong of a bond as other methods and may require drilling or punching holes in the metal.

When considering alternatives to JB Weld for bonding stainless steel, it’s crucial to think about the specific application and the necessary strength and durability of the bond. Welding may be the best option if you require a robust and permanent bond that can withstand high stress. Alternatively, cyanoacrylate glue might be more suitable if you’re looking for a quick fix.

Conclusion

In summary, JB Weld is a top-notch adhesive for bonding stainless steel. Its impressive strength, durability, and versatility make it a favorite among professionals and DIY enthusiasts alike. However, not all grades of stainless steel are created equal, so it’s essential to understand the properties of your specific material before selecting the appropriate JB Weld product.

To achieve optimal bonding results with JB Weld, proper surface preparation is key. Cleaning the surface thoroughly with acetone or rubbing alcohol and roughening it up with coarse grit sandpaper will ensure a strong mechanical bond.

While JB Weld is cost-effective and easy to use, it does have its limitations. Extreme temperatures or flexing may cause it to fail, and its long curing time may not be practical for some projects requiring immediate use.

If JB Weld isn’t suitable for your particular application, don’t fret. There are alternatives such as epoxy adhesive, cyanoacrylate glue, welding, and mechanical fasteners. By considering your project’s specific requirements and weighing the pros and cons of each option, you can select the best method for achieving a reliable bond between your stainless steel parts.

Overall, whether you’re repairing broken machine parts or creating a DIY project involving stainless steel, JB Weld is an excellent choice that provides a robust connection.