Greetings, fellow welders and metalworkers.

Contents

- 1 Does Galvanized Steel Give Off Toxic Fumes When Welding?

- 2 How Galvanization Works

- 3 Potential Hazards of Welding Galvanized Steel

- 4 Understanding Zinc Oxide Fumes

- 5 The Dangers of Carbon Monoxide in Welding Galvanized Steel

- 6 Other Toxic Substances Released When Welding Galvanized Steel

- 7 Preventative Measures to Reduce Exposure to Toxic Fumes

- 8 Conclusion

It’s time to tackle a topic that may not be on the forefront of our minds when it comes to welding safety: the harmful fumes that can arise from working with galvanized steel. We all understand the importance of proper ventilation and protective gear when handling any type of metal, but it’s easy to overlook the specific dangers posed by galvanized steel.

So sit back, grab your favorite cup of joe, and let us enlighten you about the toxic fumes that can arise from welding with galvanized steel.

Does Galvanized Steel Give Off Toxic Fumes When Welding?

This material is highly sought after in various industries for its ability to withstand corrosion. But when it comes to welding galvanized steel, there are certain health risks you should take into consideration.

One of the primary concerns with welding galvanized steel is the emission of toxic fumes. This is due to the zinc coating on the steel, which releases harmful substances when heated at high temperatures. These fumes can cause metal fume fever, a condition that presents flu-like symptoms such as chills, fever, and body aches. Prolonged exposure can also result in severe health consequences.

But that’s not all. Welding galvanized steel also releases other toxic substances like lead, cadmium, and chromium. Inhaling these substances can lead to respiratory irritation, lung damage, and even cancer.

And here’s the kicker – the danger of toxic fumes from welding galvanized steel doesn’t just affect the welder. Those working nearby and even bystanders can also be exposed to these fumes, making it crucial to take proper safety measures in the workplace.

So how can you protect yourself and others from these risks? Here are some essential precautions to keep in mind when working with galvanized steel:

- Ensure proper ventilation: It is crucial to have effective ventilation systems in place to remove fumes from the work area and replace them with clean air. This will minimize exposure to toxic substances.

- Wear personal protective equipment (PPE): Protect yourself from inhalation and skin contact with toxic substances by wearing respiratory masks, gloves, and coveralls while working with galvanized steel.

- Receive adequate training: It is vital to be aware of the potential hazards of welding galvanized steel and how to handle it safely. This includes proper techniques for ventilation, handling and disposing of galvanized steel, and recognizing the signs and symptoms of exposure to toxic fumes.

How Galvanization Works

Welding galvanized steel may seem like a simple task, but it requires extensive knowledge and careful precautions to ensure safety and efficacy. As a galvanization specialist, I am here to guide you through the process and share valuable tips that will make your welding experience a breeze.

First and foremost, it is crucial to understand the purpose of galvanization. This intricate process involves coating steel or iron with zinc to prevent rusting. This not only provides an extra layer of protection but also enhances the durability and longevity of the material.

Now, let’s delve into the specifics of welding galvanized steel. The zinc coating on galvanized steel can pose challenges during welding, resulting in weaker and more prone to break welds. Hence, it is imperative to use the appropriate welding rod and gas mixture for galvanized steel. It is recommended to opt for a low-zinc welding rod and a gas mixture with high levels of carbon dioxide for robust and seamless welds.

As with any welding procedure, safety should be a top priority. There are five crucial measures for welding galvanized steel safely: adequate ventilation, wearing protective gear (such as a respirator and gloves), using the correct welding rod and gas mixture, maintaining distance from weld fumes, and proper storage of galvanized products. These precautions not only safeguard against inhaling toxic fumes but also ensure the longevity of your welds.

Speaking of storage, it is vital to store galvanized products correctly to maintain their corrosion-resistant properties. These products should be stored in a dry area away from moisture or chemicals that could potentially damage the zinc coating. With proper storage, galvanized products can last for decades without rusting.

For visual learners, I have included a video tutorial demonstrating the best techniques for welding galvanized steel. This resource offers a step-by-step guide on effectively and safely welding this material.

In conclusion, welding galvanized steel is an essential yet potentially hazardous process.

Potential Hazards of Welding Galvanized Steel

Welding galvanized steel can be a daunting task, but with the right knowledge and precautions, you can successfully tackle this project. As a welding specialist, I have witnessed firsthand the potential hazards of working with galvanized steel. In this segment, I will divulge the top dangers associated with welding galvanized steel and how you can safeguard yourself from them.

Noxious Vapors:

One of the most significant perils of welding galvanized steel is the toxic vapors it emits. Galvanized steel is coated with a layer of zinc, which when heated, releases hazardous fumes that can cause severe respiratory complications. These vapors contain zinc oxide, which can lead to breathing difficulties, coughing, and chest discomfort. Overexposure to these fumes can even result in long-term health concerns. To avoid these vapors, ensure proper ventilation in your workspace and wear a respirator mask.

Burns from Sparks and Splatter:

Another risk of welding galvanized steel is the intense sparks and scorching splatter it produces. These tiny sparks and splatter can easily burn your skin or clothes if you’re not careful. Always don protective gear, including gloves, aprons, and a welding helmet with a face shield to shield yourself from these hazards.

Metal Fume Fever:

The fumes from welding galvanized steel can also cause metal fume fever, commonly known as “zinc chills.” This condition presents flu-like symptoms such as fever, chills, nausea, and headaches. It is crucial to take breaks during the welding process and limit your exposure to these fumes.

Eye Damage:

Welding operations produce intense light that can damage your eyes if not adequately protected. The bright light from welding galvanized steel can cause flash burns or arc eye, similar to sunburn in the eye. Always wear a welding helmet with a suitable shade lens to protect your eyes from these harmful rays.

Electrical Shock:

Understanding Zinc Oxide Fumes

As a welder, you are well acquainted with the hazards of the job, including the perilous fumes that come with it. But did you know that welding galvanized steel can release toxic fumes, specifically zinc oxide? In this segment, we will delve deeper into comprehending these fumes and their impact on your health.

The Perils of Zinc Oxide Fumes

Extended exposure to welding fumes, particularly zinc oxide, poses significant health risks. These hazards include damage to the lungs and various forms of cancer such as lung, larynx, and urinary tract cancer. Furthermore, specific fumes can result in metal fume fever, stomach ulcers, kidney damage, and harm to the nervous system.

A Closer Look at Metal Fume Fever

One of the most prevalent health hazards associated with zinc oxide fumes is metal fume fever. This flu-like illness presents symptoms such as a metallic taste in the mouth, headaches, fever, and chills. Although it may seem like a mild sickness, it should not be taken lightly as prolonged exposure can lead to severe health complications.

Who is at Risk?

Welders who engage in thermal cutting, welding, and melting are often exposed to zinc oxide fumes. This is due to the fact that when certain metals are heated, they emit zinc oxide in the form of fumes. It is therefore imperative for welders to take precautions to protect themselves from these toxic emissions.

Precautions to Consider

To ensure your safety while welding galvanized steel, it is vital to take the following precautions:

Wear appropriate protective gear such as respirators, gloves, and goggles to prevent inhalation and contact with fumes.

Work in a well-ventilated area or utilize local exhaust ventilation systems to minimize exposure to fumes.

Take regular breaks and step away from the welding area periodically to avoid prolonged exposure.

Employ proper welding techniques to reduce the amount of fumes produced.

The Dangers of Carbon Monoxide in Welding Galvanized Steel

[The Dangers of Carbon Monoxide in Welding Galvanized Steel]

When it comes to your profession as a welder, you are well aware of the inherent risks involved. You are no stranger to the potential dangers of working with high heat and metal, such as burns, eye injuries, and hearing loss. However, there is another peril that often goes overlooked in your line of work – carbon monoxide (CO) produced from welding galvanized steel.

What is Galvanized Steel?

Galvanized steel is a type of steel that has been coated with a layer of zinc to protect against rust and corrosion. This process typically involves dipping the steel in molten zinc or using an electroplating method. The addition of zinc offers an extra layer of durability and longevity to the steel, making it a popular choice in industries such as construction and automotive manufacturing.

The Hidden Danger of Welding Galvanized Steel

While galvanized steel may have its benefits, it also poses a hidden danger to welders. During the welding or cutting process, the high levels of heat can cause the zinc coating to vaporize and release toxic fumes. These fumes primarily consist of zinc oxide and zinc chloride, both of which can be harmful if inhaled.

The Risks of Inhaling Zinc Oxide and Zinc Chloride Fumes

Exposure to zinc oxide fumes can result in metal fume fever, a condition similar to the flu with symptoms such as chills, fever, body aches, and fatigue. While this fever typically resolves within 24-48 hours, it can still cause significant discomfort and hinder your ability to work effectively.

In contrast, zinc chloride fumes can irritate the respiratory system and cause symptoms like coughing, chest pain, and difficulty breathing. Prolonged exposure to these fumes can also lead to more severe respiratory problems, including chronic bronchitis.

The level of toxicity from these fumes can vary depending on the amount and duration of exposure.

Other Toxic Substances Released When Welding Galvanized Steel

If you are a welder, you are well aware of the potential dangers that come with your profession. From scorching sparks and extreme temperatures to flying debris and electrical shocks, the job requires constant awareness and precaution. However, there is one peril that may not be as widely recognized – the hazardous substances emitted when welding galvanized steel.

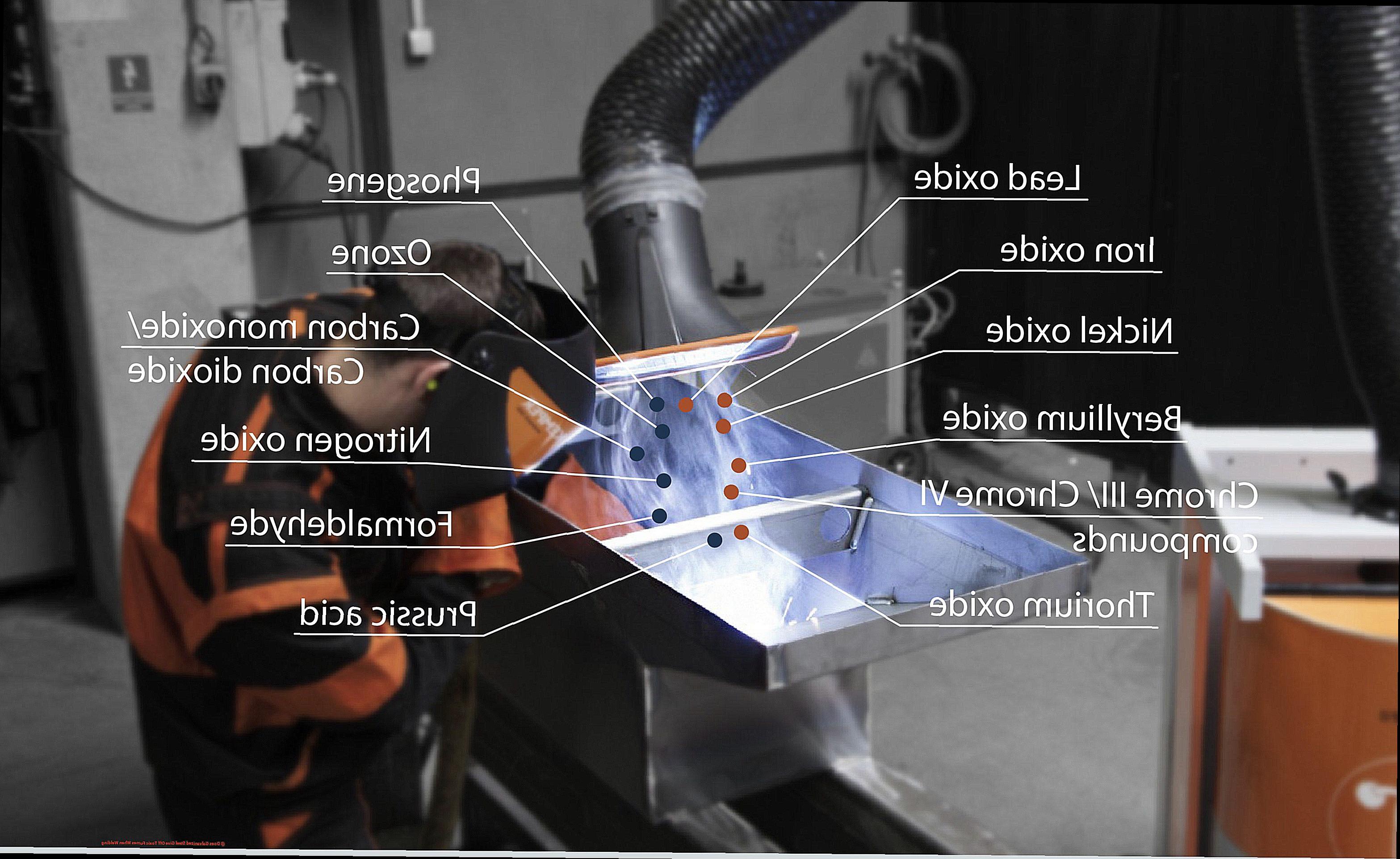

Galvanized steel is a type of steel coated with zinc for added strength and protection against rust and corrosion. While this may seem like a beneficial feature, it comes with its own set of risks. When heated during the welding process, galvanized steel can release a plethora of toxic substances, including carbon dioxide, carbon monoxide, ozone, nitrogen oxides, organic gases, and degreasing solvent gases.

The decomposition of fluxes used in welding under high heat produces carbon dioxide. This gas can cause dizziness, headaches, and fatigue if inhaled in high quantities. Another byproduct of welding galvanized steel is carbon monoxide. It is formed when carbon dioxide shielding gas breaks down during arc welding and can lead to metal fume fever or respiratory issues.

The interaction of electric arc with atmospheric oxygen creates ozone, a highly reactive gas that is harmful when breathed in. Nitrogen oxides are also released when atmospheric oxygen and nitrogen are heated. These gases can irritate the respiratory system and cause long-term health problems.

Welding fumes contain a complex mixture of metals, metallic oxides, silicates, and fluorides. These can include toxic substances such as chromium, nickel, copper, zinc, and lead. Inhaling these fumes can result in various health issues, including lung damage and cancer.

Organic gases and degreasing solvent gases are also present when welding galvanized steel. These can be emitted from oils or greases used to lubricate the metal or from cleaning solvents used to remove any residue before welding. These gases can irritate the respiratory tract and cause headaches, dizziness, and nausea.

Preventative Measures to Reduce Exposure to Toxic Fumes

Welding may appear to be a rugged and formidable profession, but even the most resilient of welders must take precautions to safeguard themselves from the perils that lurk within their workspace. One such danger is the emission of poisonous fumes when working with galvanized steel. While these fumes may not be visible to the naked eye, they can have severe repercussions on the health of welders if proper safety measures are not taken.

So, how can one shield themselves from these toxic fumes? The first line of defense is adequate ventilation. This entails having sufficient exhaust systems in place to eliminate the fumes from the atmosphere. And no, simply opening a window or turning on a fan will not suffice. Welders should strive for a minimum of 10 air exchanges per hour in their workspace to effectively eradicate the toxic fumes and maintain a secure working environment.

However, ventilation alone is not enough. Personal protective equipment (PPE) is also essential when welding with galvanized steel. This includes donning a respirator specifically designed for welding, as well as gloves, goggles, and a welding helmet. These items serve to prevent inhalation of the fumes and protect against potential contact with the particles that can harm one’s skin and eyes.

One may also consider utilizing alternative types of steel that do not have a zinc coating, such as stainless steel or aluminum. However, if working with galvanized steel is unavoidable, another option is to remove the zinc coating before welding. This can be accomplished through grinding or chemical stripping, but it is important to note that these methods may not completely eliminate the risk of toxic fumes. Therefore, they should still be carried out in a well-ventilated area with appropriate PPE.

But perhaps the most crucial preventative measure is proper training and education for welders. Understanding the hazards associated with welding galvanized steel and how to handle them can significantly reduce exposure.

***

Also Read:

Conclusion

In conclusion, as welders and metalworkers, it is our responsibility to prioritize safety in our work. This means being aware of the potential dangers posed by welding galvanized steel and taking necessary precautions to protect ourselves and those around us.

Through this article, we have learned that when heated at high temperatures, galvanized steel can emit toxic fumes that can have serious health consequences if proper safety measures are not taken. These fumes not only affect the welder but also those working nearby and bystanders.

To minimize exposure to these harmful substances, it is crucial to ensure proper ventilation in the workspace. Additionally, wearing appropriate personal protective equipment (PPE) and receiving adequate training on handling galvanized steel safely are essential steps to take. It is also important to understand the process of galvanization and how it affects welding techniques.

We must also be mindful of other toxic substances released when welding galvanized steel, such as carbon monoxide, ozone, nitrogen oxides, and organic gases. These can also pose significant health risks if inhaled.

But do not fret – there are ways to reduce our exposure to these fumes. By implementing proper ventilation systems, wearing PPE, considering alternative types of steel or removing the zinc coating before welding, we can protect ourselves from these hazards.

Let us always keep safety as our top priority in our profession.