Are you planning on welding some chromoly to mild steel? If so, you may have a few questions about this process. I happen to have the answers.

You will learn about the advantages of welding chromoly to mild steel, and what you’ll really need for a successful welding project.

Let’s get started!

How to Weld Chromoly

Contents

- 1 How to Weld Chromoly

- 2 Can you weld chromoly to mild steel?

- 3 Can You weld chromoly to steel?

- 4 Can chromoly be MIG welded?

- 5 Can You weld 4130 to mild steel?

- 6 Can you weld chromoly with flux core?

- 7 Is mild steel better than chromoly?

- 8 Is chromoly stronger than steel?

- 9 Is chromoly stronger than Dom?

- 10 Is chromoly harder than stainless steel?

Despite the fact that welding chromoly is a little unusual and challenging, following these steps should help you succeed.

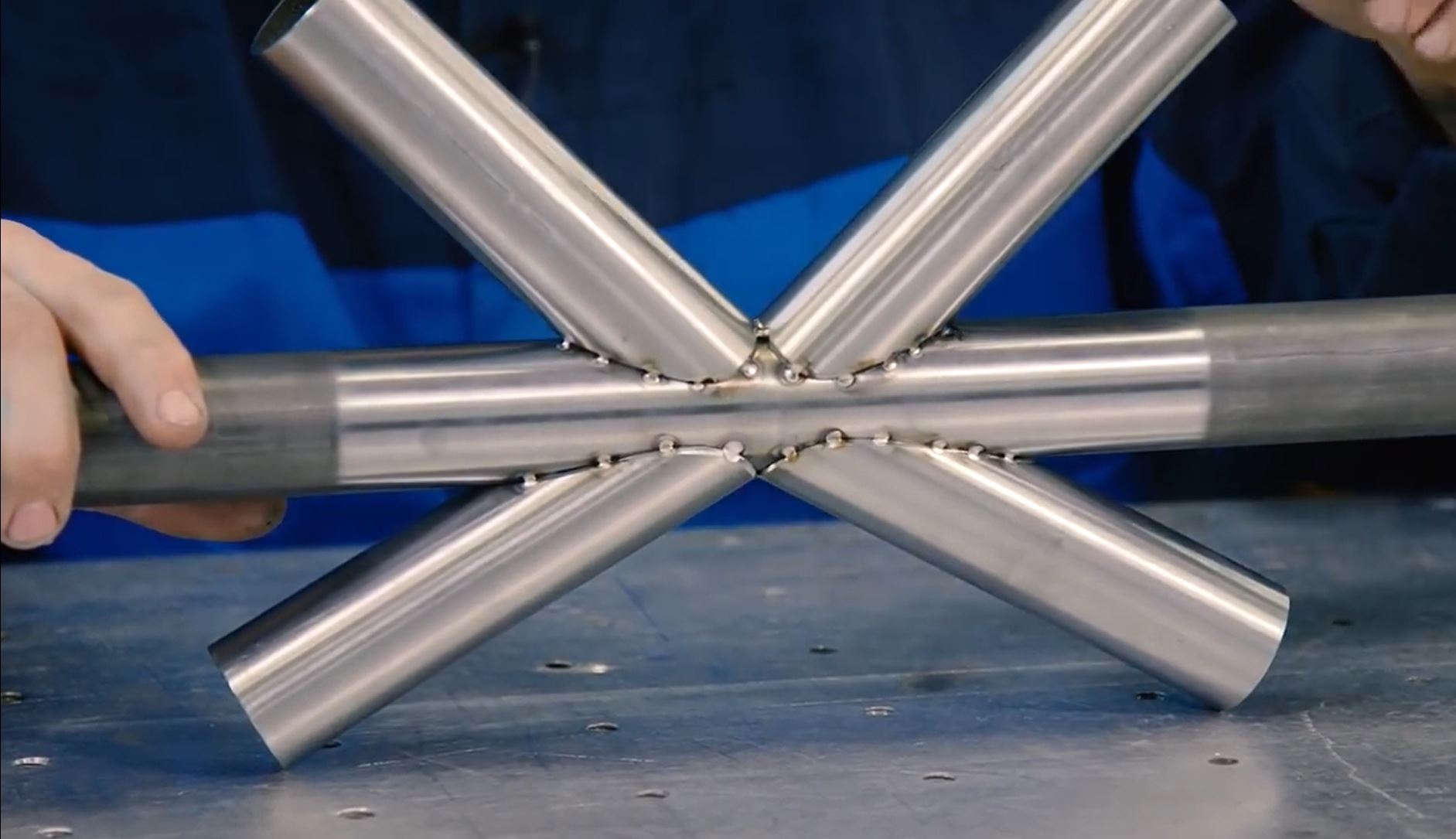

MIG or TIG welding are used to weld chromoly, and the barrier gas that is used for this is argon.

This beginner’s guide to welding chromoly will take the guesswork out of joining brass, copper, and steel.

First, you’ll need to clean away any surface contamination or welding spatter. Next, you’ll want to grind away any imperfections in the metal.

This is an important step for welding chromoly. Then, you’ll want to join the pieces together.

This is a simple three-arc process. Once the metal is welded, you will need to polish the weld.

You can finish off with a bead of black powder coat for a more attractive look.

Torch Setup

When welding chromoly, it is first necessary to understand the welder’s welding process.

The size of the welds is important: small or narrow welds are not acceptable and often require re-welding.

The welding torch’s weight and mobility will greatly aid you in securing the weld and getting the most of the welding process.

If you want to weld this alloy, you need to use a high-quality TIG welder that is properly set up and calibrated.

This alloy cannot be welded using wire-feed welders because the wire will catch on the aluminum, causing a dangerous burn.

Fitment and Tacking

Any effort to make chromoly tough introduces the risk of overspray, which can negatively affect the weld.

Some welding procedures for chromoly, such as shielded metal arc welding, are more difficult and may require more practice.

When compared to the standard arc length, smaller tacks are actually easier to handle.

You should use many little tacks rather than one larger one.

You can use fluxless welding that produces low spatter. This makes welds look better and also helps the weld stick to the base metal.

Choosing the Right Filler Materials

When welding chromoly, you first have to choose filler material.

For minor repairs, welding rods made of filler materials 2 and 4 are best. ER80S-D2 and ER70S-2 are both excellent choices for repairs.

The filler material must be compatible with chromoly, and you must choose the right filler material for the job based on the type and size of the weld joint.

This alloy is available in a variety of tempers.

The high tensile grade 4140/ 4145 is more appropriate for structural and load-bearing applications. The medium tensile grade 4130 is suitable for light-to-medium duty applications.

4130 chromoly is a chromoly welding filler that melts when exposed to heat.

It forms a puddle that fills holes and holes between the welded area and surrounding metal surfaces without the need for weld deburing.

It cannot, however, be welded with welding rod. It’s also stronger than 4130 chromoly, but it’s rarely used in welding applications.

Can you weld chromoly to mild steel?

I’d use mild steel for parts that will be exposed to lots of heat or wear and where distortion will be of less concern.

I’d use mild steel for parts that will be exposed to lots of heat or wear and where distortion will be of less concern.

I’d use this for all tig welding jobs. If you’re welding chromoly, the rods are your best option. E70S-2 steel is significantly stronger than mild steel, but it will still give quite a good weld.

Welds made of E70S-2 will be somewhat stronger than those made of mild steel, but still will lack resistance.

Can You weld chromoly to steel?

Match of chemistry is very important.

The filler metal needs to be of high carbon steel grade, and the chromoly steel should be of higher grade. Otherwise, the weld will not provide the right amount of strength.

If the chromoly steel has to be toughened after welding, a filler with even higher strength such as 6011 should be used.

Steel alloys should be used in tough welding situations. Alloys can be hardened using welding without losing their mechanical properties.

Can chromoly be MIG welded?

TIG or MIG welding type s are generally preferable to the MIG flux cored welding type.

This is due to more effective arc heating, higher production rates, and lower spatter levels.

Preheat is usually not required, but time should be monitored to ensure adequate heat input.

TIG welding is a good option because it provides better control over the weld puddle, which is important in chrome-moly.

120-in, a 300F-400F preheating is recommended.

3.3 arc welding rods (MIG guns) can be used for both TIG and MIG welding. Certain 3.3 rods can also be used for oxy-fuel welding.

All of these arc welders can be controlled using digital TIG controllers.

ER80S-D2 is a popular filler due to its high melting point and adequate corrosion resistance.

Is chromoly steel a mild steel?

Chromoly steel is a low alloy steel that derives its name from its high chromium content.

Chromoly steel is used in many industrial settings because of its strength and durability. This steel is very resistant to wear and corrosion.

Chromoly steel is also very effective for welding.

When additional strength is needed than that of mild steel, nickel steel is a better choice. Chromoly steel is a more affordable version of nickel steel.

Can You weld 4130 to mild steel?

An ER-80S can be used to weld 4130 to mild steel, but the filler metal must be low in sulfur and controlled carbon to prevent porosity.

When welding 4130 to mild steel, the weld metal should be 4130 to match the intended use of the material. The weld should be SMAW or GTAW.

The weld joints should be visually inspected for porosity and pinholes.

AMS standard 6457A requires that the filler metal contain 90% 4130 and 10% refined steel.

This can be tricky, however. Using a better solution when welding 4130 to mild steel is possible by using filler metal.

Filler metal is specially made to create a bond between two pieces of metal without melting them together, which is what occurs with welding.

Filler metal will melt when it comes into contact with the heat source, but will stay cooler than its joining material.

This will cause the filler metal to expand slightly as it melts, creating a tighter bond.

Can you weld chromoly with flux core?

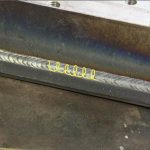

T-1 flux-cored chrome-moly wires often produce less porosity than TIG weld wire.

In addition, T-1 flux-cored wire is ductile and easy to work with.

They also produce well-shaped, homogeneous, and smooth beads with a short preheat.

When the torch-to-pig contact angle is high and no filler wire is used as the consumable, a double-arc welding process is used. This works best with thin-walled tubes.

Is mild steel better than chromoly?

In terms of tensile and yield strength, chrome steel outperforms mild steel significantly.

For the same structural support, thinner tubing may be used with Chromoly’s enhanced strength-to-weight ratio.

Because of the higher strength-to-weight ratio of chromoly steel, thicker tubes are usually required to support the same structural load, increasing weight.

When it comes to welding, chromium is much less forgiving than mild steel.

On the other hand, mild steel is less durable and can be prone to pitting and corrosion when compared to chromium.

Is chromoly stronger than steel?

Chromoly is a chrome-alloy steel developed by Arcelor Mittal, a British subsidiary of Mittal Steel.

This steel material has more than 2 times the strength of carbon steel and about 1/4 the weight of aluminum.

Chromoly steel’s unique properties are attributed to the alloying elements contained with chromium and molybdenum.

In addition to their high tensile strength, these alloys offer increased resistance to fatigue as well as corrosion and rust development.

8% to 1 .1% molybdenum concentration can be considered ideal for a chromoly frame because it’s optimal for corrosion resistance and strength.

1 percent molybdenum -alloyed steel is lighter than 2 percent chrome-alloyed steel.

We can utilize thin wall tubing since it is stronger than carbon -steel tubing.

In addition, we can take advantage of the strength that lies in the web structure of the chrom-alloy material.

Is chromoly stronger than Dom?

According to my study, chromoly is typically 20% to 25% lighter than DOM.

There’s just one explanation for this: chromoly is stronger, allowing you to utilize thinner tubing with the same level of structural integrity. It would be fascinating to observe the differences.

One difference between the two is that chromoly is slightly softer than DOM, which means better resistance to external impacts.

Another difference is that chromoly requires less finishing, meaning it will be easier to maintain the quality of your product.

The reason for this is because chromoly is forged from more premium and stronger alloys than DOM. As a result, chromoly tubing is lighter and stronger, which is a win-win opportunity for racers.

It would be easy to say that chromoly outperforms DOM in a static bending test, for example, but it doesn’t hold up very well under dynamic stress.

Also Read: Is welding hard?

Is chromoly harder than stainless steel?

Chrome moly is a high-strength, low alloy steel that has a high melting point.

Alloys are added to chromium moly steel to create the desired properties. Chrome moly is often welded to provide strength and stability due to its low co-efficient of expansion.

Chrome moly steel is prevalent in industries such as oil and gas exploration, heat exchangers, and pipelines.

Chrome moly steel is also weldable, formable, and ductile with arc welding techniques.

However, it is not recommended because of excessive spatter. Chrome moly steel has increased fatigue strength, compared to normal stainless steel.

Chrome moly steel is weldable, formable, and ductile with arc welding techniques. However, it is not recommended because of excessive spatter.