Are you tired of dealing with pesky leaks and cracks in your hot water heater? Sick of shelling out money for professional repairs?

Well, we’ve got some good news for you. Today, we’re delving into the world of hot water heaters and introducing a game-changing solution – JB Weld.

This powerful adhesive is here to save the day and your wallet. In this post, we’ll cover all the ins and outs of using JB Weld on your hot water heater – from application tricks to its long-lasting strength.

So, put on your tool belt and let’s get down to business.

Can You Use Jb Weld On A Hot Water Heater?

Contents

- 1 Can You Use Jb Weld On A Hot Water Heater?

- 2 What is JB Weld? A Brief Overview of its Properties and Uses

- 3 The Potential Risks of Using JB Weld on a Hot Water Heater

- 4 Factors to Consider Before Attempting to Use JB Weld on a Hot Water Heater

- 5 Alternative Solutions for Repairing a Leaky Hot Water Heater

- 6 Common Types of Materials Used in Hot Water Heaters and Their Compatibility with JB Weld

- 7 Safety Precautions When Using JB Weld on a Hot Water Heater

- 8 Conclusion

Before you reach for that dependable tube of epoxy adhesive, let us take a moment to delve into whether it is a suitable solution for your specific hot water heater woes.

Firstly, let us discuss what exactly JB Weld is and how it operates. JB Weld is an epoxy adhesive that has been in existence for over half a century. Renowned for its strength and versatility, it is a go-to product for various repairs and fixes. When the two components of JB Weld – resin and hardener – are combined, they create a robust bond that can withstand high temperatures and pressure. This makes it ideal for mending metal objects, such as engine parts or plumbing fixtures.

Now, let us focus on hot water heaters. These appliances are constantly exposed to extreme heat and pressure, making them susceptible to corrosion due to their constant contact with water. So, can JB Weld effectively mend a hot water heater?

The answer is yes, but with certain limitations. JB Weld is not specifically designed for hot water heaters, so it may not be able to endure exceedingly high temperatures for an extended period. However, it can be utilized as a temporary fix for minor leaks or fractures in the tank or pipes.

But before you get your hands dirty with JB Weld, there are a few things to bear in mind. Firstly, if your hot water heater is made of plastic or has a non-metallic exterior, JB Weld may not be suitable as it requires a metal surface to bond effectively. Additionally, using JB Weld on a hot water heater does not guarantee a permanent solution. The continuous exposure to heat and pressure may cause the bond to weaken over time, resulting in further leaks or cracks.

So when can you use JB Weld on your hot water heater? If you have a small leak or fracture in the tank or pipes of your metal hot water heater, JB Weld can be used as a temporary solution.

What is JB Weld? A Brief Overview of its Properties and Uses

For those who enjoy do-it-yourself projects, possessing a reliable adhesive in your toolkit is crucial. When it comes to repairing leaks and cracks in hot water heaters, nothing beats the effectiveness of JB Weld. This two-part epoxy adhesive has been trusted by professionals and amateurs alike for over half a century, thanks to its exceptional heat resistance and incredible strength. But what is JB Weld exactly, and why is it the top choice for hot water heater repairs?

What is JB Weld?

JB Weld is a two-part epoxy adhesive comprised of a resin and a hardener. When these two elements are combined, they undergo a chemical reaction that results in a robust bond capable of enduring extreme temperatures. In fact, JB Weld can withstand temperatures up to 550 degrees Fahrenheit, making it an ideal option for fixing hot water heaters.

Uses of JB Weld for Hot Water Heater Repairs

The versatility of JB Weld makes it suitable for various repair tasks, including sealing leaks and mending cracks in hot water heaters. Its high heat resistance enables it to withstand the constant temperature fluctuations in water heaters, ensuring a long-lasting repair. Additionally, JB Weld can also be used to fix the heating element in hot water heaters, prolonging the appliance’s lifespan and saving you from costly replacements.

Limitations of JB Weld as a Hot Water Heater Repair Solution

Although JB Weld is highly efficient and effective in repairing hot water heaters, it does have its limitations. It is not a permanent solution, and there may be underlying issues that require professional intervention. For instance, if the leak or crack in the hot water heater is caused by rust or corrosion, JB Weld may only provide a temporary fix. In such cases, it is best to seek assistance from a licensed plumber who can address the root cause of the problem.

The Potential Risks of Using JB Weld on a Hot Water Heater

Hot water heaters are crucial appliances in any household, providing us with luxurious warm showers and sparkling clean dishes. But when something goes awry, we often seek a quick and effortless solution. Enter JB Weld – a widely recognized adhesive product that boasts the ability to fix almost anything. However, before you reach for your reliable tube of JB Weld to mend your hot water heater, it’s important to be aware of potential risks.

To begin with, using JB Weld on a hot water heater can result in significant leaks. The adhesive is not designed to withstand high temperatures, and when exposed to the intense heat of a hot water heater, it can weaken and disintegrate. This can lead to fractures or complete detachment of the adhesive, resulting in water gushing out of the heater. This not only damages the heater itself but also poses a threat to surrounding areas such as floors, walls, and furniture.

But the hazards don’t end there. Using JB Weld on a hot water heater also presents safety concerns. If there is a leak in the heater due to the failure of the adhesive, there is a possibility of electric shock or other dangers if the water comes into contact with any electrical components. This is especially perilous if the hot water heater is situated in a cramped space or near other appliances.

In addition to safety risks, using JB Weld on a hot water heater can also impact its overall functionality. The adhesive is not intended for prolonged exposure to water and can deteriorate over time. This can cause a decrease in efficiency and potentially lead to higher energy bills. And if the JB Weld fails and leaks occur, it can disrupt the heating system, resulting in irregular or no supply of hot water.

Moreover, using JB Weld on a hot water heater may nullify any warranty or insurance coverage.

Factors to Consider Before Attempting to Use JB Weld on a Hot Water Heater

Envision this – you awaken to indulge in a steaming shower, only to discover that your heated aquatic heater is oozing. Panic sets in as you hastily search for a solution. And then it dawns upon you – the mystical product that boasts of mending anything – JB Weld.

But before you grab that tube of JB Weld, there are some vital factors you must consider. As a specialist in implementing JB Weld for repairs on heated aquatic heaters, I’m here to impart my expertise and experience with you.

Material Matters

The initial thing you must know is the material of your heated aquatic heater. JB Weld is specifically formulated for utilization on metallic surfaces, so if your heated aquatic heater is composed of plastic or fiberglass, it may not be the optimal choice for repairs.

Temperature Troubles

JB Weld is a bonding adhesive, which means it necessitates heat to successfully adhere. However, an excess of heat can also cause the adhesive to become brittle and fail. Make certain to check the maximum temperature limit of the JB Weld product you’re using and ensure it can withstand the temperature of your heated aquatic heater.

Identify the Source

Before reaching for that tube of JB Weld, it’s imperative to identify the source of the discharge or damage. If it’s emanating from a junction or seam, then JB Weld may be an effective solution. However, if the leak is originating from a fissure or aperture in the tank itself, JB Weld may not be a long-term resolution, and you may need to contemplate other options.

Surface Preparation Is Key

Proper surface preparation is critical for any repair job, and utilizing JB Weld on a heated aquatic heater is no exception. Make sure to thoroughly cleanse the surface and eliminate any rust or debris that may impede the bonding process.

Alternative Solutions for Repairing a Leaky Hot Water Heater

Not only is it frustrating and inconvenient, but it can also be quite costly if not addressed properly. However, don’t worry, as there are alternative solutions available to help fix this issue. As an expert in repairing leaky hot water heaters, I have extensively researched and compiled information on the most effective methods for tackling this problem.

Option 1: Replace the Entire Unit

If your hot water heater is old and has multiple leaks, it may be time to consider replacing the entire unit. While this may seem like a daunting and expensive task, it can actually save you money in the long run. A new hot water heater will be more energy-efficient and less likely to develop leaks, ultimately saving you on energy bills and potential repair costs.

Option 2: Repair the Specific Part Causing the Leak

Sometimes, the leak may be caused by a specific part of the hot water heater, such as a valve or pipe. In such cases, repairing or replacing that specific part may be a more cost-effective solution than replacing the entire unit. However, it is crucial to accurately identify the source of the leak before attempting any repairs.

Option 3: Use a Temporary Patch or Sealant

For those looking for a quick fix, products like JB Weld can serve as a temporary patch or sealant for a leaking hot water heater. This type of epoxy adhesive can bond to various materials and is often used as a short-term solution for leaks. However, it should not be considered a long-term fix and may even cause further damage if not used correctly.

Factors to Consider Before Choosing a Repair Method

Before making a decision on which repair method to use, there are several essential factors to consider. These include the material of your hot water heater (e.g. metal or plastic), the appropriate temperature for bonding (if using a sealant or adhesive), and properly preparing the surface for successful repair.

Common Types of Materials Used in Hot Water Heaters and Their Compatibility with JB Weld

Hot water heaters may seem insignificant, but they play a crucial role in our daily routines. Whether it’s a comforting shower or clean dishes, we rely on these appliances to provide us with hot water whenever we need it.

But have you ever pondered the materials that go into constructing a hot water heater? In this article, we will delve into the common types of materials used in hot water heaters and their compatibility with JB Weld, a renowned epoxy adhesive.

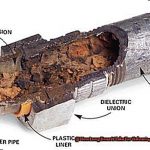

Let’s begin by examining the key components of a hot water heater. The tank is the most vital part of the appliance as it holds and heats the water. Typically made of steel or glass-lined steel, it boasts durability and insulation properties. The tank is then wrapped with insulation and an enamel metal jacket to maintain the water’s temperature inside. To protect against corrosion, one or two magnesium or aluminum anode rods are placed inside the tank. These rods selflessly sacrifice themselves to safeguard the tank from rust and deterioration.

But what relevance does this have to JB Weld? Well, when facing a leak or crack in a hot water heater, many individuals turn to JB Weld for its dependable bond strength. However, using JB Weld on a hot water heater may not be the best course of action. Let’s break down why.

Firstly, JB Weld performs best on clean and dry surfaces. If applied to a functioning hot water heater, the heat and moisture can compromise its bond strength. This can result in leaks or cracks, causing more harm than good. Moreover, the chemicals in JB Weld may react with the metal surface of the tank, leading to corrosion and rusting.

Furthermore, hot water heaters come in various sizes, usually ranging from 40 to 80 gallons. The size you require depends on your household’s needs and how many appliances utilize hot water. For larger households, a bigger tank may be necessary to meet their requirements.

Safety Precautions When Using JB Weld on a Hot Water Heater

When faced with a hot water heater repair, using JB Weld can be a convenient and cost-effective choice. But before diving into the process, it is crucial to prioritize safety measures to ensure a successful and secure repair.

The first step is to carefully read and follow the instructions on the package. JB Weld is a two-part epoxy adhesive, meaning it comprises two components – resin and hardener – that must be mixed in equal parts. It’s essential to mix these components on a disposable surface and evenly spread the mixture using a popsicle stick or other flat object.

Before applying JB Weld, ensure that the surface area to be repaired is clean and dry. Any moisture or debris can impact the adhesion and strength of the repair. It’s also advisable to test compatibility on a small area first, especially if you’re unsure how JB Weld will react with your specific surface.

When applying JB Weld on one surface, make sure to apply an even layer for maximum strength. Additionally, give sufficient drying and curing time for the repair to set properly. Typically, JB Weld requires at least 4-6 hours for drying and 24 hours for curing before any weight or stress can be applied to the repaired area.

One potential concern when using JB Weld on a hot water heater is its reaction to heat and moisture. The heat from the water heater may affect the curing process, so it’s crucial to allow enough time for the repair to set before using hot water. Also, keep in mind that moisture can weaken the bond of JB Weld, so ensure that the repaired area stays dry during the curing process.

Another safety measure to consider is using a release agent on surfaces where you don’t want JB Weld to adhere to. This can be particularly helpful when working with complex surfaces or when trying to remove excess JB Weld after application.

In conclusion, repairing a hot water heater with JB Weld can be a practical and efficient solution.

Conclusion

In conclusion, we hope this article has provided you with valuable insights and information about the potential use of JB Weld on a hot water heater. As avid DIY enthusiasts, we understand the frustration of dealing with leaks and cracks in our appliances. That’s why we introduced you to JB Weld – a revolutionary adhesive that can save you time and money on professional repairs.

Throughout this article, we have delved into the properties of JB Weld and its effectiveness in repairing hot water heaters. While it may not be a permanent solution, it can serve as a temporary fix for minor leaks or fractures. However, before reaching for your trusty tube of JB Weld, it’s important to consider certain factors such as the material of your hot water heater and the source of the leak.

We also highlighted some potential risks associated with using JB Weld on a hot water heater, including possible leaks, safety hazards, and impact on functionality. It is crucial to follow safety precautions when using this adhesive to ensure a successful repair.

Moreover, we explored alternative solutions for repairing a leaky hot water heater and discussed the compatibility of different materials with JB Weld. Armed with this knowledge, you can make an informed decision when faced with hot water heater repairs.