Have you ever seen a piece of wood transformed into a stunning work of art through the mesmerizing technique of fractal burning? If not, you’re missing out on something truly spectacular. This unique process involves using high voltage electricity to create intricate patterns and shapes on the surface of wood.

But here’s the question: can you use a welder for fractal burning? If you already have welding experience, you might be wondering if you can use your trusty welding gear to achieve these beautiful patterns. The answer is yes, but it’s not as simple as just diving in.

There are several factors to consider when using a welder for fractal burning. The type of welder you have, the power settings, and the accessories you use all play crucial roles in achieving the desired outcome of your project.

In this blog post, we’ll delve into the world of fractal burning and explore how to harness the capabilities of your welder to create stunning burn patterns. We’ll cover essential safety precautions and necessary tools and accessories. Plus, we’ll provide a step-by-step guide to help get you started with fractal burning using your welder.

Let’s dive in together.

What is Fractal Burning?

Contents

Look no further than Fractal Burning, also known as Lichtenberg Wood Burning. This technique uses high voltage electricity to create intricate designs on wood’s surface, resulting in stunning and one-of-a-kind pieces.

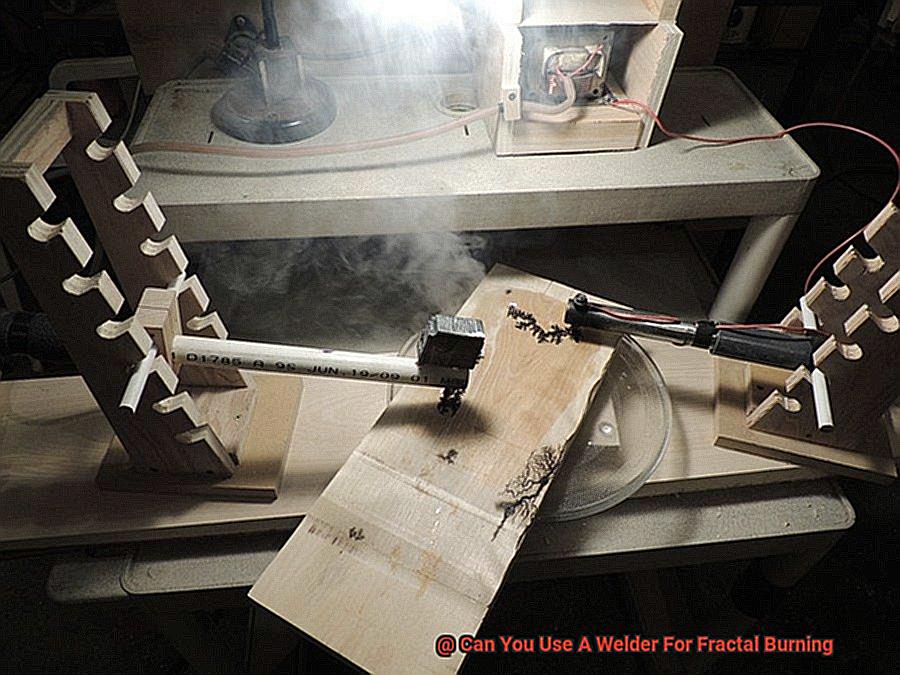

To create Fractal Burning designs, first, the wood is sanded and cleaned thoroughly. Then, a conducting solution or electrolyte is applied to the surface of the wood, allowing for even electricity flow. An electrode connected to a high voltage power source is then brought close to the wood’s surface, creating a conductive path for electrical discharge. The result? Unique branching patterns that look like lightning strikes or tree branches.

While the designs created by Fractal Burning are nothing short of remarkable, it’s essential to take appropriate precautions when dealing with high voltage electricity. Protective gear and working in a well-ventilated area are a must to ensure safe enjoyment of this art form.

Fractal Burning works best on hardwoods such as oak and maple, and proper preparation of the wood surface is crucial for optimal results. But once you have everything in place, you’ll find that the designs created through Fractal Burning are truly awe-inspiring.

What is Welding?

You’ll be interested to know about welding – a technique used to join two or more metal pieces together by melting them.

Welding is an essential part of many industries, including construction, manufacturing, automotive, and aerospace. Without it, we wouldn’t have the infrastructure we rely on every day. Welding plays a critical role in creating structures and repairing equipment.

There are several types of welding techniques available, each with its own pros and cons. The most common methods include arc welding, MIG welding, TIG welding, and stick welding. Each technique requires different tools and approaches to melt and join the metal pieces.

However, welding is not just about melting metal. It requires a great deal of skill and expertise to be done correctly.

A welder needs to have knowledge of different types of metals, how they behave when heated and cooled, and how to use the tools properly.

Safety is also a crucial factor in welding as there are many hazards involved in working with high temperatures and electrical currents.

Can You Use A Welder for Fractal Burning?

If so, fractal burning, also known as Lichtenberg burning, may be the perfect artistic process for you. However, before jumping into this unique technique, it’s important to have the right equipment.

One piece of equipment that can be used for fractal burning is a welder. However, not all welders are suitable for this task. In order to successfully use a welder for fractal burning, you need a machine that can produce high voltage, low amperage electricity. This type of electricity is essential for creating the intricate patterns associated with fractal burning without damaging the wood.

If your welder doesn’t produce high voltage, low amperage electricity, don’t worry. There is still hope. You can modify your welder to make it usable for fractal burning. To do so, you’ll need to install a transformer that can step up the voltage while reducing the amperage. This crucial modification will allow your welder to produce the necessary high voltage, low amperage electricity that is perfect for fractal burning.

However, it’s important to note that modifying a welder requires technical expertise and should only be attempted by professionals.

If you’re interested in trying out fractal burning using a welder, make sure to consult with an expert to ensure that your machine can handle the necessary modifications.

Preparing the Wood Surface

Before you start wielding that welder, it’s crucial to prepare your wood surface properly. As an expert in this area, I’m excited to guide you through the necessary steps for a safe and successful fractal burning experience.

First things first, ensure that the wood surface is completely dry. Any moisture in the wood can cause it to warp or crack when exposed to high heat from the welder. So, give it at least two weeks to dry before proceeding.

Next up, sanding the wood surface is essential to remove any rough spots or debris that may interfere with the burning process. A smooth and even surface will guarantee beautifully consistent and clean burn lines.

Once you’ve sanded down, grab a damp cloth and wipe away any remaining sawdust or dirt from the wood surface. This is a crucial step since it’ll also prevent any fires caused by loose debris catching fire during the fractal burning process.

Lastly, seal the deal with a protective finish on the wood surface. This coat will help prevent damage caused by heat or moisture and enhance the appearance of your burn lines.

Setting Up the Welder for Fractal Burning

Before jumping in, it’s crucial to set up your welder correctly for optimal results and safety. Let’s explore how to do it.

First things first, you need a welding machine with a high amperage rating – at least 60 amps for fractal burning. The grounding clamp and cable should be fastened securely to the wood surface you’re working on, while the electrode holder or wand should have a copper-coated electrode for stable current flow.

Once you have all the necessary tools and materials, let’s connect them. Start by attaching the grounding clamp to your wood piece and linking it to the welder with the grounding cable. Then, insert the electrode into the holder or wand and tighten it firmly before connecting it to the appropriate cable.

But wait, there’s more. Before starting your project, test your setup by creating a small burn on a scrap piece of wood. This will allow you to fine-tune your settings and ensure everything is working correctly.

Remember that safety is paramount when working with high voltage electricity. Be sure to follow all manufacturer instructions and guidelines, taking precautions such as wearing protective gear and keeping flammable materials away from your workspace.

With these steps in mind, you’re ready to unleash your creativity and bring stunning fractal burn patterns to life. You’ll be amazed at how easy it is to set up your welder for fractal burning once you have the right tools, materials, and knowledge.

Safety Precautions When Using a Welder for Fractal Burning

Before you begin, it’s crucial to prioritize safety. Fractal burning, which involves using an electric current to create patterns on wood, can be dangerous if proper precautions are not taken. Here are some essential safety tips to keep in mind when using a welder for fractal burning:

First, make sure you’re wearing the appropriate protective gear. Safety glasses, gloves, and a respirator mask are must-haves to protect against inhaling toxic fumes. Fractal burning produces fumes that can be harmful if inhaled, so don’t take this lightly.

Proper ventilation is also essential. Make sure you work in a well-ventilated area or use a fume extractor to reduce the risk of inhaling toxic fumes.

In addition, have a fire extinguisher nearby. The process of fractal burning can create sparks and flames, so it’s crucial to have a fire extinguisher on hand in case of an emergency.

When working with electrical equipment near water, use a ground fault circuit interrupter (GFCI) outlet. This type of outlet helps prevent electrical shocks and is an important safety feature.

Finally, be aware of your surroundings. Ensure people and pets are kept at a safe distance while you’re working, and make sure there are no flammable materials nearby.

eA9_XRL2I0A” >

Conclusion

To sum it up, using a welder for fractal burning is indeed possible, but it’s not for the faint-hearted. This electrifying technique involves using high voltage electricity to create intricate designs on wood’s surface. However, before you get started, you need to make sure you have the right equipment and take proper safety precautions.

When it comes to equipment, a welding machine with a high amperage rating and a copper-coated electrode is crucial for stable current flow. But modifying your welder requires technical expertise and should only be attempted by professionals who know what they’re doing.

Safety is also paramount when working with high voltage electricity. It’s essential to wear protective gear such as safety glasses, gloves, and respirator masks at all times. And if you’re working in an enclosed space, make sure you have adequate ventilation or use a fume extractor to reduce the risk of inhaling toxic fumes.

With these tips in mind, you can unleash your creativity and create stunning fractal burn patterns while keeping yourself safe. Whether you’re working on oak or maple hardwoods, proper preparation of the wood surface is key to achieving optimal results.