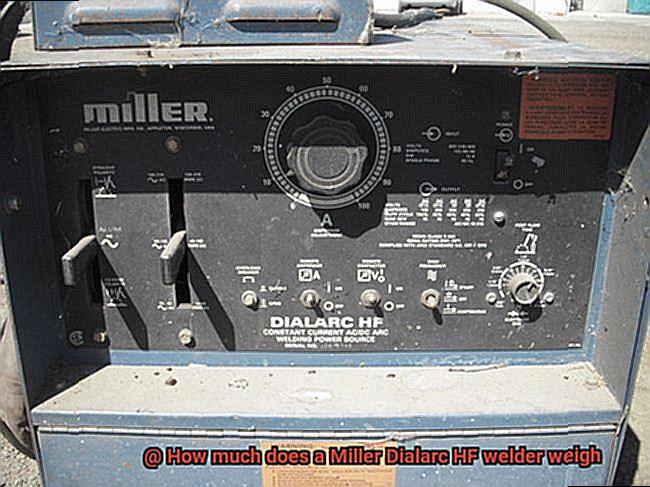

Are you planning to move your Miller Dialarc HF welder but unsure about its weight? Don’t worry; we’ve got you covered. Welding is a demanding task that requires a robust and powerful machine like the Miller Dialarc HF welder, which is popular among welders for its reliability and excellent performance.

Knowing the weight of this machine is crucial when planning transportation, as it will determine the mode of transportation required. The weight of the Miller Dialarc HF welder varies depending on the model, ranging from 350lbs to 400lbs. Although this may seem like a daunting weight to handle, it’s essential to note that the machine’s weight is a testament to its durability and strength.

Whether you’re a professional welder or DIY enthusiast, having accurate information about the weight of the Miller Dialarc HF welder is vital to ensure safe lifting and transportation. In this blog post, we’ll explore various models of Miller Dialarc HF welders, their respective weights, and why it’s crucial to know their weight.

So, let’s get started.

Types of Miller Dialarc HF Welders

Contents

If you’re looking for a powerful and reliable welding machine, you can’t go wrong with a Miller Dialarc HF welder. These welders are available in different types, each with unique features and specifications to suit various welding needs. In this article, we’ll explore the various types of Miller Dialarc HF welders, their capabilities, and what sets them apart.

One critical factor to consider when choosing a Miller Dialarc HF welder is its weight. Depending on the type and configuration, the weight can vary significantly. For instance, the Dialarc HF-P is a portable model that weighs around 238 pounds and has a maximum output of 250 amps. It’s perfect for fieldwork and construction sites where mobility is essential.

The Dialarc HF-250 is a versatile welder that can handle MIG, TIG, and Stick welding with ease. With a maximum output of 250 amps, it’s ideal for heavy-duty industrial applications. Weighing approximately 375 pounds, it’s slightly heavier than the Dialarc HF-P but still easy to move around.

For heavy industrial use, the Dialarc HF-310 is an excellent choice. This welder weighs around 580 pounds and has a maximum output of 310 amps. It can weld materials up to 5/8 inch thick, making it perfect for extended welding times and high amperage applications.

Finally, the most potent model in the Dialarc HF series is the Dialarc HF-320. With a maximum output of 320 amps, it can easily handle heavy-duty industrial welding applications that require welding materials up to 3/4 inch thick. At approximately 625 pounds, it’s the heaviest model in the series but still portable enough to move around when necessary.

Weights of Common Models

If you’re on the hunt for a welding machine that can tackle heavy-duty projects with ease, the Miller Dialarc HF Welder should be at the top of your list. However, one crucial factor to consider is the weight of the machine. In this article, we’ll take a deep dive into two popular models of the Miller Dialarc HF Welder and explore their respective weights.

When it comes to welding equipment, weight is a critical factor to consider. The Miller Dialarc HF welder is no exception. The weight of a machine can impact its portability and ease of use, particularly for those who need to transport it frequently.

Let’s get into the specifics. The Miller Dialarc HF AC/DC 250 Welder weighs 387 pounds, which includes the power source, water cooler, and running gear. This model is designed for heavy-duty welding applications and has a maximum output of 250 amps. It’s an excellent choice for those who need a reliable machine for demanding welding projects.

If you’re looking for a machine that can handle even more demanding welding applications, the Miller Dialarc HF AC/DC 310 Welder may be the way to go. This model weighs 523 pounds (including power source, water cooler, and running gear) and has a maximum output of 310 amps. It’s ideal for those who require a heavy-duty machine that can tackle intense welding projects with ease.

It’s essential to keep in mind that additional accessories or features added to the unit can add extra pounds to the overall weight of your welding machine. So, it’s always best to double-check the weight of your specific model before purchasing or transporting it.

Factors That Affect Weight

The first factor to consider is the type of welder you choose. A Miller Dialarc HF welder can come in different types, such as stick or TIG, and each type has its own unique components and mechanisms that contribute to its overall weight.

The second crucial factor is the size and dimensions of the machine. Generally, larger and more powerful welders tend to be heavier than their smaller counterparts. Additionally, the shape and design of the machine can also play a role in its weight. Some Miller Dialarc HF welders may have a more streamlined, compact design, while others may be bulkier or have a larger frame.

Finally, any additional features or accessories that come with your Miller Dialarc HF welder can impact its overall weight. For example, a unit with an extended power cord or cooling system may be heavier than one without these features.

Considerations for Transporting the Welder

Weighing in at a hefty 400 pounds, it’s important to keep safety in mind before moving the machine from one location to another.

To make the process easier, you can consider using a heavy-duty hand truck or dolly. However, it’s essential to ensure that the hand truck can handle the weight of the welder and has sturdy wheels and a secure locking mechanism. Your goal is to avoid any potential damage to the machine or injuries during transportation.

For longer distances or rough terrain, using a forklift or crane may be the best option. However, it’s vital to follow proper safety protocols to avoid accidents while lifting and moving heavy machinery.

No matter how you choose to transport your welder, it’s crucial to secure it correctly during transit. Using straps or chains to hold the machine in place and padding or blankets to prevent damage is a must.

Safety Tips for Moving a Heavy Welder

Moving a heavy welder, such as a Miller Dialarc HF, can be a challenging and potentially dangerous task if proper safety measures aren’t taken. But with the right equipment and precautions, you can move your welder safely and efficiently. Here, we’ll go over some safety tips to keep in mind when moving a heavy welder.

Use Appropriate Lifting Equipment

The first step in moving a heavy welder is to use the right lifting equipment. A forklift or overhead crane is ideal for moving such heavy machinery. If you don’t have access to such equipment, consider hiring a professional moving company that specializes in moving heavy machinery.

Wear Proper Personal Protective Equipment (PPE)

When moving a heavy welder, it’s crucial to wear appropriate PPE, including gloves and steel-toed boots. These will protect your hands and feet from any potential injuries if the welder accidentally drops.

Clear Your Pathway

Clearing the path is essential before moving the welder. Make sure the path is clear of any obstacles or hazards, including loose debris, cables, or wires that could trip you or cause the welder to tip over.

Secure the Welder

Before you start moving the welder, make sure it is securely fastened to the lifting equipment. Double-check all the straps and chains to ensure they are tight and won’t come loose during transport.

Use Caution When Maneuvering

When moving the welder, use caution and move slowly to avoid any sudden movements that could cause it to tip over. If you’re moving the welder up or down stairs, take extra care to ensure it doesn’t slip or slide.

Get Help

Moving a heavy welder is not a one-person job. Always enlist the help of at least one other person who understands how to lift and move heavy objects safely.

By following these safety tips, you can ensure that you move your Miller Dialarc HF welder safely and efficiently without causing any injury or damage to yourself or the equipment.

OwJ-NAyzcYo” >

Conclusion

To sum up, the Miller Dialarc HF welder is a robust and dependable machine that many welders favor due to its exceptional performance. However, it’s essential to be aware of the weight of this device before transporting it. The machine’s weight varies depending on the model, ranging from 238 pounds to 625 pounds.

The weight of a welding machine can significantly impact its portability and ease of use, especially for those who need to move it frequently. Therefore, it’s crucial to consider factors such as type, size, dimensions, and any additional features or accessories that come with your Miller Dialarc HF welder.

When moving a heavy welder like the Miller Dialarc HF, safety should always be the top priority. It’s crucial to use appropriate lifting equipment, wear proper personal protective equipment (PPE), clear your pathway, secure the welder correctly, use caution when maneuvering and get help from at least one other person who understands how to lift and move heavy objects safely.

In conclusion, knowing accurate information about how much a Miller Dialarc HF welder weighs is vital for safe lifting and transportation.