Have you ever wondered what it’s like to work in one of the most challenging and isolated environments on earth? Imagine being perched high atop a towering oil rig, surrounded by nothing but endless sea. The sun never sets, and temperatures can soar to scorching levels. It’s a demanding job that takes nerves of steel and unwavering focus, but for those who thrive on challenges, working as an oil rig welder can be highly rewarding.

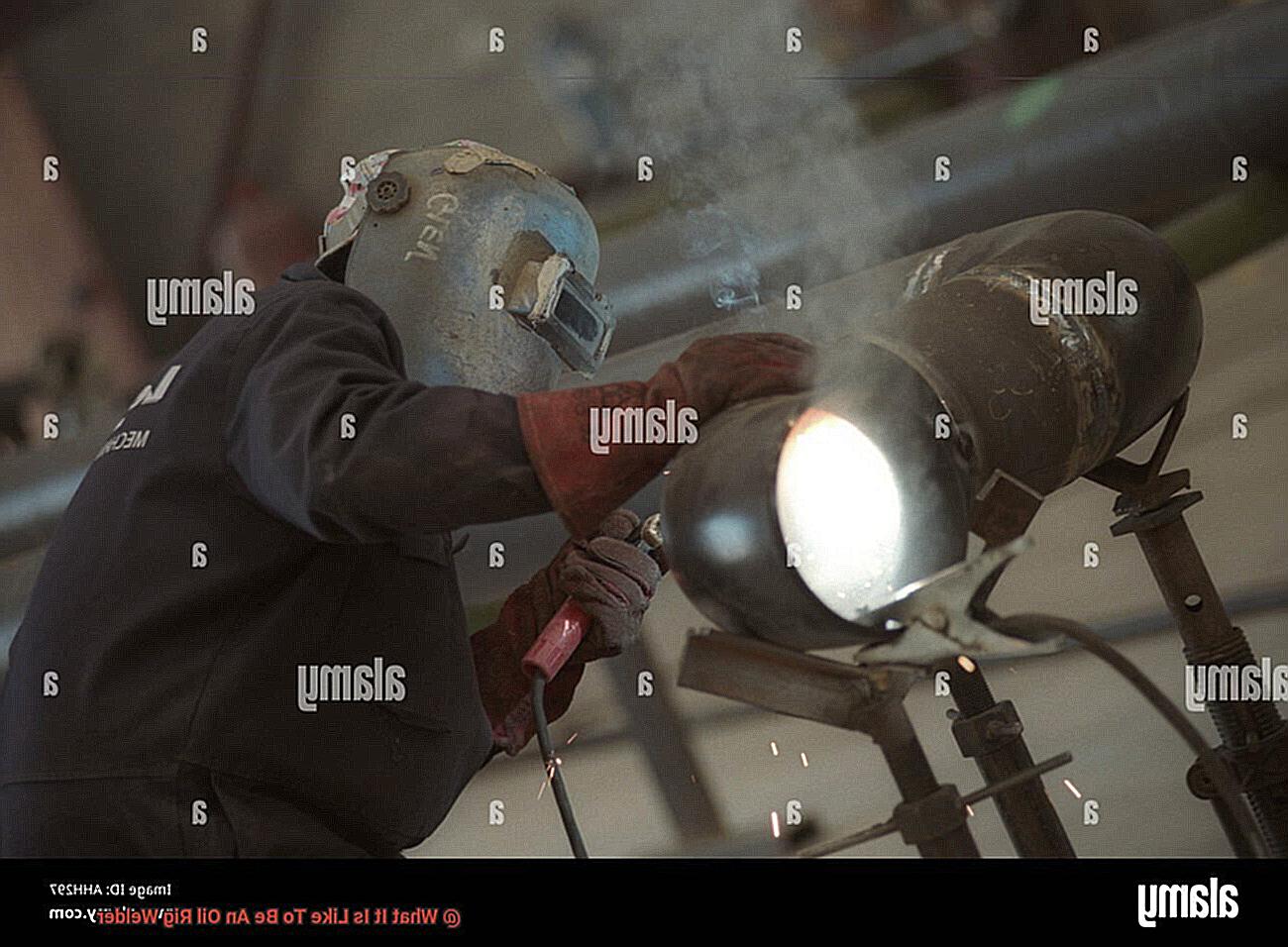

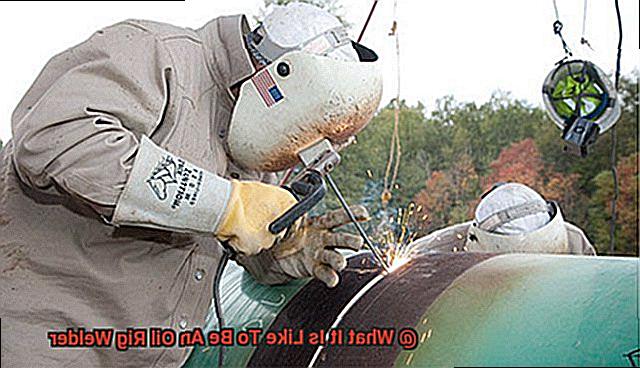

As an oil rig welder, you play a critical role in maintaining and repairing the essential infrastructure of offshore drilling platforms. Your responsibility is to weld metal structures, pipelines, and equipment together, ensuring they are strong enough to withstand the brutal elements of the sea. This job demands precision, attention to detail, and deep knowledge of welding materials and techniques.

But it’s not just about technical skill – working as an oil rig welder also requires physical stamina and mental fortitude. You’ll often work long hours in cramped spaces with heavy machinery while being mindful of the risks associated with electricity and gases. Emergencies such as fires or accidents can occur at any moment in this high-pressure environment.

Despite these challenges, becoming an oil rig welder is an opportunity to make a good living while advancing your career. It’s a job that will demand your best every day, but it can also provide you with a deep sense of accomplishment and pride in your work. So if you’re ready for hard work and willing to face the elements head-on, then this could be the perfect career for you.

The Challenging Aspects of Being an Oil Rig Welder

Contents

If you’re considering a career as an oil rig welder, get ready for a job that demands physical and mental toughness. As an expert in welding, I can assure you that the role comes with a set of unique challenges.

One of the biggest hurdles of being an oil rig welder is enduring the harsh working conditions. Oil rigs are often located far from civilization, in remote areas subject to extreme weather conditions. This means that welders must be able to work in all types of weather, including high winds, heavy rain, and extreme heat or cold.

Long hours and demanding schedules are also part of the job. Most oil rigs operate 24/7, and welders may have to work shifts that last from 12 to 16 hours. Furthermore, oil rig welders may be away from home for weeks or even months at a time due to rotational schedules.

Technical skill and attention to detail are essential for oil rig welders to succeed. Welding on an oil rig requires precision and accuracy since even the slightest mistake can have severe consequences. Oil rig welders must be familiar with different welding techniques and materials.

Safety risks are also present on oil rigs, which are inherently dangerous environments. Accidents can occur at any time, so oil rig welders must work safely and follow strict safety protocols to avoid injury or accidents.

Despite these challenges, many oil rig welders find the role satisfying. Being part of a team that extracts valuable resources from the earth is exciting and unique. If you love welding and enjoy working with your hands, a career as an oil rig welder may be ideal for you.

Working in Extreme Weather Conditions

Oil rig welders are a breed of workers who face some of the toughest environments on the planet. They work with precision and accuracy while adhering to strict safety protocols to extract valuable resources from the earth. However, one of their most significant challenges is working in extreme weather conditions.

Whether it’s the blistering heat of the desert, the freezing cold of the Arctic, or the high winds of a storm, oil rig welders must be ready for anything. In extreme heat, they take precautions to prevent heat exhaustion and dehydration by wearing protective clothing and staying hydrated. Conversely, in extremely cold temperatures, they must safeguard themselves from frostbite and hypothermia by wearing appropriate clothing and taking frequent breaks in heated areas.

Working in high winds can also present its own set of challenges, making it difficult for oil rig welders to maintain their balance while welding at heights. Flying debris can create a hazardous work environment, and that’s why it’s crucial for workers to wear appropriate personal protective equipment (PPE) such as safety glasses and hard hats.

Despite these obstacles, oil rig welders are proud to be part of a vital industry that powers our world. They understand that their work is necessary to keep our world moving forward, and they take pride in knowing that they are contributing their skills to this important cause.

Safety Risks Associated with Oil Rig Welding

With high stakes involved in oil rig welding, it’s crucial to address significant safety risks that could jeopardize the well-being of workers.

One of the most pressing concerns for oil rig welders is the potential for fire and explosions. Welding involves high heat, sparks, and flammable materials, which can create combustible environments on offshore oil rigs. Workers must navigate this dangerous terrain with caution by taking extra care to prevent fires and explosions from occurring.

Another potential hazard is electrical shock. Welding equipment relies on electricity to function, and on oil rigs where wet and salty conditions are prevalent, the risk of electrocution increases. Proper training in electrical safety procedures is essential to prevent serious injuries or fatalities.

Heat-related illnesses such as heat exhaustion and heatstroke are also significant risks for oil rig welders. The heat generated during welding, combined with hot and humid conditions on oil rigs, can cause severe health problems if not appropriately managed. Frequent breaks, hydration, and appropriate clothing are necessary to prevent overheating.

Respiratory hazards are another crucial concern for oil rig welders. The welding process produces fumes and gases that can be hazardous if inhaled. On offshore oil rigs, workers may also be exposed to toxic substances such as lead, zinc, and cadmium. Wearing proper respiratory protection is vital to avoid long-term health problems.

To mitigate these risks, oil rig welders must receive extensive safety training and follow strict safety protocols while on the job. This includes wearing appropriate personal protective equipment (PPE), such as flame-resistant clothing, gloves, and respirators. Regular inspections of equipment are also necessary to maintain a safe work environment.

Physical Demands of the Job

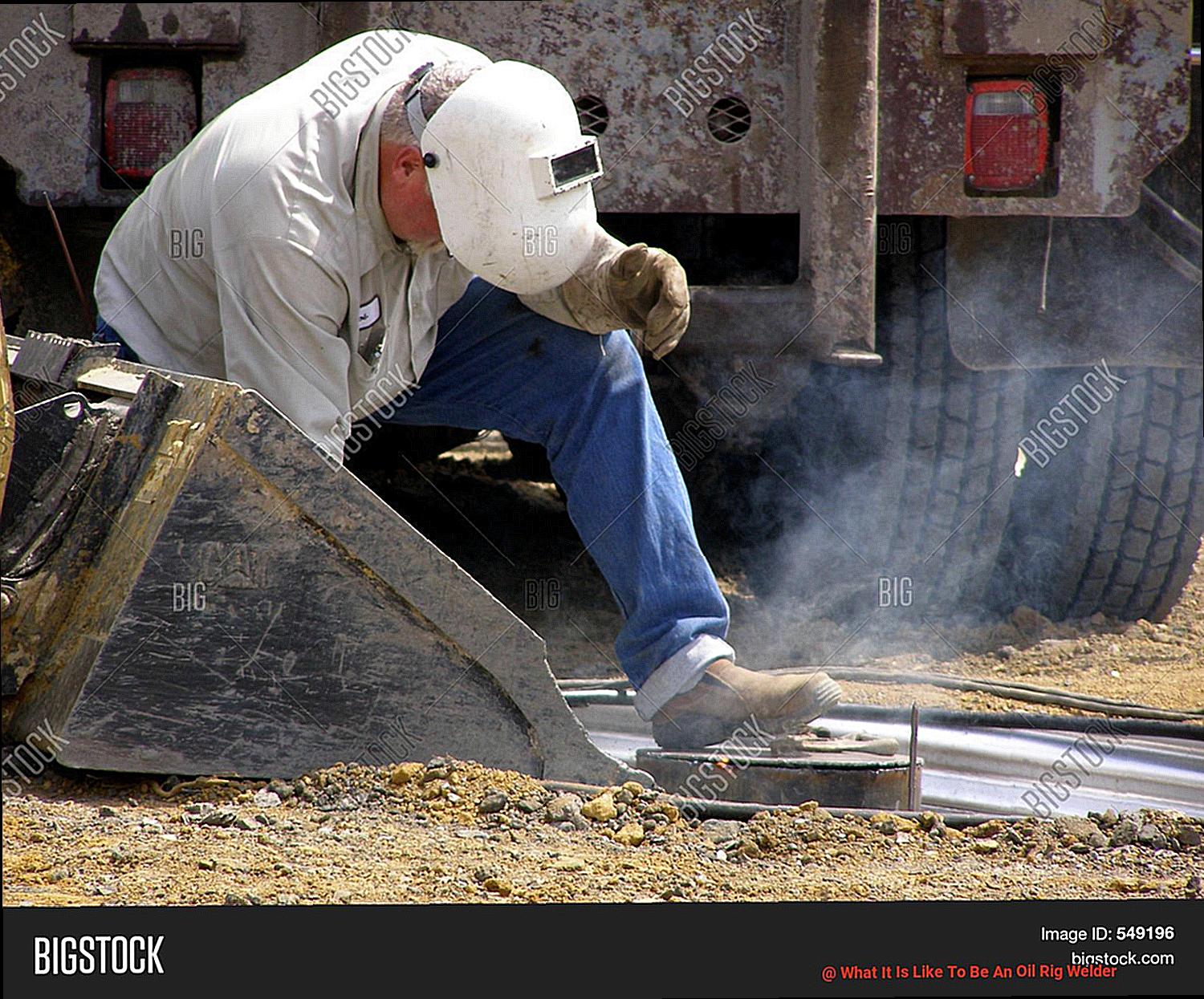

As an oil rig welder, you are in for a physically demanding job that requires a high level of fitness and endurance. You will work long hours in harsh weather conditions, often in remote locations. So, if you’re up for a challenge and enjoy working with your hands, this could be the ideal profession for you.

One of the main physical demands of the job is heavy lifting. As an oil rig welder, you will move and lift heavy equipment and materials such as pipes and welding machines. This can put a significant strain on your body, particularly your back and shoulders. To prevent injury, it’s critical to use proper lifting techniques, wear supportive gear, and take breaks when necessary.

In addition to heavy lifting, welding also involves standing and bending for extended periods. Working in cramped spaces often means maneuvering yourself into tight spots and holding awkward positions for long periods. Therefore, you must possess good flexibility, strength, and endurance.

Furthermore, oil rig welders must be prepared to work in all weather conditions. This means withstanding extreme temperatures, high winds, rain, and even snow or ice.

The job can be physically exhausting, but it is incredibly rewarding for those who enjoy working with their hands and being part of a team.

Enjoyment and Sense of Accomplishment from the Work

Oil rig welders take immense pride in their work and the crucial role they play in the success of oil drilling operations.

Working as a team is one of the most enjoyable aspects of being an oil rig welder. On an oil rig, every worker has a crucial job to do, and welders are no exception. They work alongside their colleagues to ensure that the operation runs smoothly and efficiently. This shared purpose and camaraderie can be incredibly fulfilling.

In addition to working together, oil rig welders relish the challenge of operating in a unique and demanding environment. Oil rigs are often located in remote areas, and workers must adapt to living and working in close quarters with their colleagues. The job itself is physically demanding and requires a high level of skill and precision. For some oil rig welders, the opportunity to work in these conditions can be invigorating.

Finally, oil rig welders derive a great sense of accomplishment from their work. Welding is a skilled trade that requires years of training and experience to master, and oil rig welders take pride in knowing that they are experts in their field.

Their work is essential to the functioning of the oil drilling operation, which can have significant economic and environmental implications. Knowing that their work has a tangible impact on society can be incredibly rewarding for oil rig welders.

Qualifications Needed to Become an Oil Rig Welder

If you’re looking for a challenging and rewarding career in the oil and gas industry, becoming an oil rig welder might be the perfect fit. However, to pursue this career path, certain qualifications and skills are required.

To start off, having a high school diploma or equivalent is generally necessary. But to really stand out as an oil rig welder, post-secondary education in welding is highly recommended. This can be obtained through vocational schools or community colleges that offer welding programs.

But education alone won’t cut it. On-the-job training is also essential for those seeking to become oil rig welders. This training involves working under experienced welders and learning how to use specialized equipment and techniques specific to the oil rig industry.

If you’re considering becoming an oil rig welder, you should also possess a unique set of skills. These include physical dexterity, attention to detail, and the ability to work in hazardous conditions. Oil rig welders must be able to work at heights and in confined spaces for long periods of time. They must also have a strong understanding of safety protocols and procedures to ensure their own safety and the safety of their colleagues.

Certification is another crucial aspect of this profession. The American Welding Society offers certifications in various welding processes that are recognized in the industry. These certifications demonstrate a level of expertise and knowledge, which can lead to higher paying positions and greater opportunities for advancement.

-Fab3vjQOdI” >

Conclusion

To sum up, being an oil rig welder is not a job for the faint-hearted. It requires a combination of mental and physical toughness, exceptional precision, attention to detail, and deep knowledge of welding materials and techniques. Oil rig welders work in one of the most challenging and isolated environments on earth, enduring harsh weather conditions while maintaining and repairing essential infrastructure.

The job demands physical strength as it involves heavy lifting, standing for extended periods, bending over in cramped spaces, and adapting to extreme temperatures. The mental demands are equally high as working with heavy machinery while being mindful of the risks associated with electricity and gases can be mentally exhausting. Emergencies such as fires or accidents can happen at any moment in this high-pressure environment.

Despite these challenges, becoming an oil rig welder offers a highly rewarding opportunity to make a good living while advancing your career. Being part of a team that extracts valuable resources from the earth is exciting and unique. Oil rig welders take immense pride in their work and derive great satisfaction from knowing that their work has a tangible impact on society.

If you’re considering pursuing this career path, certain qualifications are required: having a high school diploma or equivalent; post-secondary education in welding is highly recommended; on-the-job training; physical dexterity; attention to detail; ability to work in hazardous conditions; strong understanding of safety protocols and procedures; certification by recognized organizations.