Picture this: it’s the middle of the night, and you hear a strange gurgling noise coming from your bathroom.

You go to investigate, only to find that your PVC pipe has cracked and water is spraying everywhere. Panic sets in as you realize that no plumber will be available until morning.

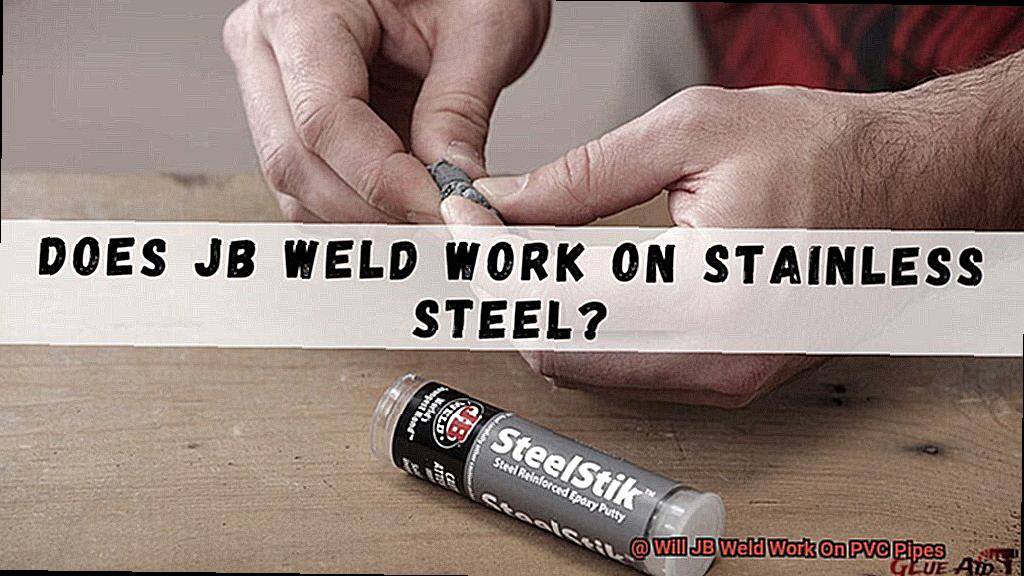

What can you do? Many people turn to JB Weld as a quick and easy fix for their PVC pipe woes, but does it really work?

The answer is yes, JB Weld can work on PVC pipes. However, before you start slathering the adhesive on your damaged pipe, there are some important things you need to know.

What exactly is JB Weld made of, and how does it bond with PVC? Can it withstand high pressure or extreme temperatures?

And most importantly, is it safe for drinking water? In this blog post, we’ll delve into all of these questions and more to help you determine if JB Weld is the right solution for your plumbing emergency.

So, whether you’re a DIY enthusiast or just someone who wants to be prepared for unexpected plumbing disasters, join us as we explore how to fix a cracked PVC pipe with JB Weld.

Properties of PVC Pipes

Contents

PVC pipes are nothing short of remarkable, given their impressive properties that have made them a go-to solution for a wide range of applications.

Made from polyvinyl chloride, a type of plastic, PVC pipes are known for their high durability, strength, and low cost. Let’s dive into the fascinating properties of PVC pipes that make them ideal for plumbing and other applications.

One of the most significant benefits of PVC pipes is their resistance to corrosion and chemical damage. Unlike other materials such as iron or copper, PVC pipes do not rust, which makes them a perfect choice for industrial settings where corrosive substances may be present.

This property contributes to the longevity and reliability of PVC pipes, ensuring that they remain robust and efficient over time. Another essential property of PVC pipes is their ability to withstand high pressure and temperature.

These pipes can handle temperatures of up to 140°F and pressures of up to 200 PSI, making them suitable for use in irrigation systems and water supply lines. Their durability and strength play a crucial role in ensuring that plumbing systems remain safe and long-lasting.

PVC pipes are also lightweight, easy to install, and have a smooth interior surface that minimizes friction, allowing for efficient flow of fluids. Their lightness and ease of installation make them an attractive option for quick installation without compromising on quality.

However, it’s important to note that PVC pipes do have limitations. One significant drawback is their tendency to become brittle over time when exposed to UV light.

This can lead to cracking and leaks in the pipes, particularly in outdoor applications. Additionally, PVC pipes are not recommended for use with hot water or steam as they can soften and deform under high temperatures.

When it comes to repairing PVC pipes, many people wonder if JB Weld is suitable. JB Weld is a two-part epoxy adhesive that can bond metals, plastics, ceramics, and wood.

The answer isn’t straightforward as it depends on the type of PVC pipe and the conditions under which the repair is being made. In general, JB Weld is not recommended for use on PVC pipes that are under constant pressure or subject to high temperatures.

However, in some instances, JB Weld may provide a temporary fix for small repair areas that are not under constant pressure. In conclusion, understanding the properties of PVC pipes is crucial in determining their suitability for various applications.

PVC pipes are resistant to corrosion and chemical damage, durable, and strong enough to handle high pressure and temperature.

Does JB Weld Work on PVC Pipes?

While PVC pipes are known for their durability, they can still suffer from damage over time. If this happens, JB Weld can be a potential solution for repairing small cracks or holes in PVC pipes.

However, it is crucial to note that JB Weld is not recommended for pressurized systems like water or gas lines. The heat generated during the welding process can cause the PVC to warp or melt, leading to leaks or even burst pipes.

Therefore, if you have pressurized system damage that needs repair, it’s best to consult with a professional plumber or other expert in PVC pipe repair. Assuming your PVC pipe isn’t under pressure and the damaged area is easily accessible, using JB Weld can be a viable solution.

Start by ensuring that the area to be repaired is clean and dry. Next, mix the two parts of JB Weld together according to the instructions provided with the product.

Apply the mixture directly to the damaged area of the PVC pipe, making sure to completely cover the affected area. It’s important to keep in mind that JB Weld takes time to cure fully.

Depending on your environment’s temperature and humidity, it may take up to 24 hours for the epoxy to fully harden. During this time, it’s essential to avoid disturbing the repair area.

Advantages and Disadvantages of Using JB Weld on PVC Pipes

When it comes to repairing PVC pipes, JB Weld can be a game-changer.

This two-part epoxy is known for creating a strong and durable bond that can help prevent leaks and other issues. However, before you rush to apply it, it’s crucial to understand the advantages and disadvantages of using JB Weld on PVC pipes.

Advantages

Strong Bond

One of the most significant benefits of using JB Weld on PVC pipes is its ability to create a robust and long-lasting bond. The adhesive can help form a seal that is tough enough to withstand various types of pressure, eliminating the need for multiple repairs.

User-Friendly

Another advantage of JB Weld is its ease of use.

The two-part epoxy can be mixed together and applied to the damaged area using a brush or applicator, making it an ideal option for DIY enthusiasts looking for a quick fix.

Chemical Resistant

JB Weld is also known for its excellent resistance to chemicals, making it an ideal option for PVC pipes that may come into contact with various substances. This feature ensures that the adhesive remains strong even in harsh conditions.

Disadvantages

Not Specifically Designed for PVC Pipes

Although JB Weld can be used on PVC pipes, it is not specifically designed for this purpose. Therefore, it may not be as effective when used on PVC pipes as other options.

Limited Flexibility

Another potential disadvantage of using JB Weld on PVC pipes is that it may not provide the same level of flexibility as other options, such as PVC cement or plumber’s putty.

This lack of flexibility can cause the bond to weaken or break over time.

Long Curing Time

Finally, one of the biggest drawbacks of using JB Weld on PVC pipes is its long curing time. It typically takes at least 4-6 hours to cure and may take up to 24 hours to fully harden.

This can be inconvenient for those who need a quick fix for their PVC pipe issue. In conclusion, while there are some advantages to using JB Weld on PVC pipes, there are also some potential drawbacks to consider.

Other Alternatives to JB Weld for PVC Pipe Repairs

JB Weld may be the go-to option for repairing PVC pipes, but it’s not the only option available.

There are several alternatives that can be used depending on the extent of the damage and the type of repair needed. Let’s explore some of them.

One alternative to JB Weld is PVC pipe cement. This cement is specially designed for bonding PVC materials together and can be used to repair small cracks or leaks in PVC pipes.

It’s important to note that PVC pipe cement should not be used for structural repairs or repairs in high-pressure systems. So, if you’re dealing with a small crack or leak in your PVC pipe, this could be the perfect solution for you.

Another option for PVC pipe repairs is using a patch kit. These kits typically include a piece of flexible material like rubber or silicone, that can be wrapped around the damaged area of the pipe and secured in place with clamps or adhesive.

Patch kits are ideal for repairing small cracks or holes in PVC pipes and can provide a temporary fix until a more permanent solution can be implemented. For more extensive repairs, replacing the damaged section of the PVC pipe may be necessary.

This process involves cutting out the damaged section and replacing it with a new section of PVC pipe and fittings. It’s crucial to ensure that the new section is properly secured and sealed to prevent future leaks or damage.

While JB Weld can be effective for certain types of PVC pipe repairs, it’s important to consider other options as well. By considering alternatives like PVC pipe cement, patch kits, or replacing the damaged section of the pipe, you can ensure a successful and long-lasting repair.

Remember to always read and follow instructions carefully and take appropriate safety precautions when using any repair method. In summary, don’t limit yourself to just JB Weld when repairing your PVC pipes.

Tips for Repairing PVC Pipes with JB Weld

PVC pipes are a crucial part of many plumbing systems, but they can be prone to damage and leaks. Fortunately, repairing PVC pipes with JB Weld is a great solution – if you know what you’re doing. Here are six tips to help you repair PVC pipes using JB Weld like a pro.

Clean and Dry the Pipe

Before attempting any repairs, make sure the pipe is completely clean and dry. Wipe away any debris or moisture from the affected area with a clean cloth or rag. Any foreign substances can compromise the strength and effectiveness of the adhesive, so take your time with this step.

Sand Lightly

Lightly sand the surface of the PVC pipe to create a rough surface for the JB Weld to bond to. This will result in a stronger repair that lasts longer. However, be careful not to sand the area too aggressively, as this can cause damage to the PVC pipe.

Use a PVC Primer

To increase the chances of a successful repair, use a PVC primer before applying the JB Weld. This will help soften the surface of the PVC pipe and make it more receptive to adhesives. Apply the primer evenly and wait for it to dry completely before moving on.

Apply Thin Layers

Apply thin layers of JB Weld to the affected area. This will allow each layer to fully cure before applying additional layers, resulting in a stronger and more effective repair. Remember: less is more. Only use a small amount of JB Weld and spread it evenly over the affected area.

Let it Cure Properly

After applying the JB Weld, let it cure properly before testing the repair. Follow the instructions on the packaging for recommended curing times, as this can vary depending on the specific product being used. Rushing this step can compromise the strength of your repair.

Protect Yourself

JB Weld can be difficult to remove once it has cured on skin, so protect yourself by wearing gloves when handling the adhesive. Additionally, work in a well-ventilated area to prevent exposure to strong fumes during application and curing.

Safety Considerations When Working With JB Weld

First, it’s crucial to wear protective gloves and eyewear when handling JB Weld.

This will shield your skin and eyes from potential irritation or damage. In addition to protective gear, it’s also vital to work in a well-ventilated area.

JB Weld contains chemicals that can release harmful fumes and vapors if inhaled over an extended period of time. To avoid this, work in an open space or use a respirator mask if using JB Weld for an extended period.

Another critical safety consideration is to avoid ingesting JB Weld. It should never come into contact with food or beverages as this can cause serious health issues.

Lastly, keep JB Weld away from children and pets. Store the product in a secure area where curious hands or paws cannot access it.

i8TBhTqRFWU” >

Conclusion

In conclusion, JB Weld can be a lifesaver when it comes to repairing PVC pipes.

However, it’s important to keep in mind that this two-part epoxy adhesive has its limitations and requires proper usage. PVC pipes are known for their durability and resistance to corrosion and chemical damage, making them an ideal choice for plumbing systems.

But even the toughest materials can suffer from wear and tear over time, resulting in leaks or cracks. That’s where JB Weld comes in handy.

This versatile adhesive can bond metals, plastics, ceramics, and wood with ease. But when it comes to PVC pipes, you need to be careful.

While JB Weld can be used for small repairs that aren’t under constant pressure, it’s not recommended for pressurized systems like water or gas lines. Before applying JB Weld on your PVC pipe, make sure the area is clean and dry.

Once applied directly to the damaged area of the pipe, allow ample time for the mixture to cure before testing the repair. While JB Weld has many advantages such as creating a strong bond and being user-friendly, there are also potential drawbacks such as limited flexibility and long curing times.

Depending on the extent of damage, alternatives such as PVC pipe cement or patch kits may also be suitable. Safety should always come first when working with any adhesive material like JB Weld.