Wrought iron is a timeless material that has been used for centuries to create stunning gates, railings, and other decorative features in homes and commercial buildings.

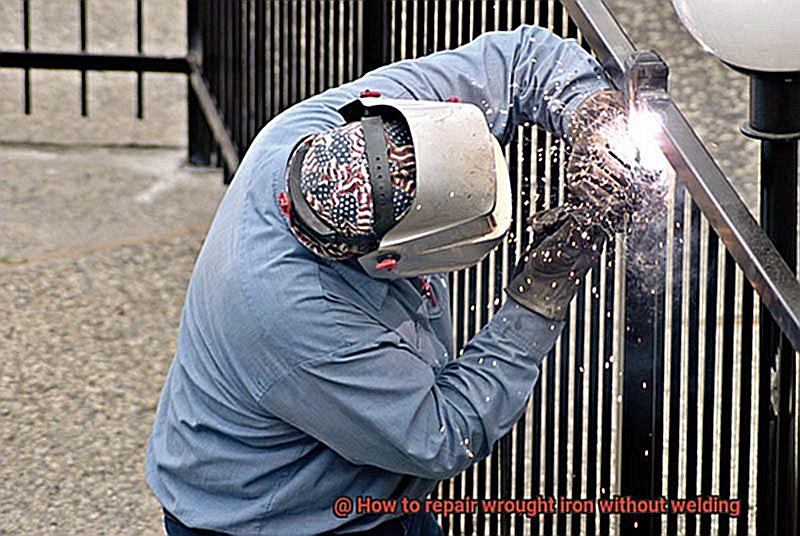

However, even the toughest wrought iron surfaces can fall victim to damage and corrosion over time, resulting in unsightly rust spots and weakened areas that compromise the structure’s safety. While welding may seem like the obvious solution to fix the damage, not everyone has the necessary tools or expertise to perform a welding repair job.

Fortunately, there are alternative methods available for repairing wrought iron without welding. In this blog post, we’ll explore various ways you can restore wrought iron without welding.

We’ll cover everything from using epoxy putty to fill in holes and scratches to utilizing aluminum brazing rods to mend small cracks and breaks. You’ll also find invaluable tips on prepping your surface for repair and ensuring a successful outcome.

Whether you’re an avid DIY enthusiast or a homeowner looking to make some much-needed repairs, this guide will equip you with all the knowledge you need to restore your wrought iron structures without welding. So why wait?

Let’s dive in now.

Overview of Welding as a Repair Method

Contents

There are several ways to repair your wrought iron without resorting to welding. Let’s first examine welding as a repair method.

Welding involves melting the metal and joining it with a filler material. Although it is a highly effective way to repair wrought iron, it requires specialized equipment and training.

Incorrectly done welding can cause further damage to the metal. So what are the alternatives?

One option is using epoxy, a two-part adhesive that bonds metal surfaces together. Clean the damaged area and apply epoxy to both sides before firmly pressing them together.

Once dried, sand down any excess and paint over the repaired area. Another option is utilizing mechanical fasteners like bolts or screws.

This technique involves drilling holes through both sides of the damaged area and inserting bolts or screws to hold the pieces together. To prevent rust, use stainless steel or galvanized fasteners.

Once in place, use an epoxy filler or putty to create a smooth surface before painting. For small cracks or breaks, use a metal bonding agent instead of epoxy.

Metal bonding agents are specifically designed for bonding metal surfaces together and work similarly to epoxy. While welding may be the most popular solution for repairing wrought iron, it’s important to note that it’s not always necessary.

With epoxy, mechanical fasteners, or metal bonding agents, you can effectively repair your wrought iron without welding experience or equipment. However, if you do decide to go with welding as a repair method, make sure to hire an experienced welder and check if your wrought iron piece is suitable for additional welding repairs.

There are alternative methods to repair it without the need for welding.

Alternative Methods of Repairing Wrought Iron Without Welding

Wrought iron is a timeless material that can withstand the test of time.

But even the most durable wrought iron pieces can succumb to wear and tear or accidental damage. While welding is often the go-to method for repairing wrought iron, it may not be the best option for everyone.

Fortunately, there are alternative methods available that can be just as effective and safer to use.

Epoxy

One of the popular options for repairing wrought iron without welding is epoxy.

Epoxy is a two-part adhesive that creates an incredibly strong bond when mixed together. It’s particularly suitable for small repairs, such as fixing a broken scroll or finial.

To use this method, start by cleaning the broken area thoroughly with a wire brush and sandpaper. Then, apply the epoxy to the broken area and hold the pieces together until the adhesive sets.

Brazing

Another alternative method is brazing. This process involves heating the broken area with a torch and then applying a filler metal that melts at a lower temperature than the wrought iron.

The filler metal then flows into the gap and solidifies, creating a robust bond between the two pieces. However, brazing requires some skill and experience to execute properly.

For those who prefer not to use heat, cold welding can be used as an alternative.

Cold welding is a process where two metals are bonded together using pressure instead of heat.

To use this method, start by cleaning the broken area thoroughly with a wire brush and sandpaper. Then, apply a cold welding compound to the broken area and press the pieces together until the adhesive sets.

It’s important to note that each alternative method has its own unique advantages and disadvantages. For example, while epoxy is easy to use and suitable for small repairs, it may not be strong enough for larger repairs.

Brazing requires some skill and experience but can be used for more extensive repairs, while cold welding is ideal for those who prefer not to use heat. In conclusion, if you’re looking for an alternative method to repair your wrought iron piece without welding, there are several options available.

It’s essential to choose the right method for your specific repair needs to ensure a long-lasting repair that will stand up over time.

Using Epoxy to Repair Wrought Iron

Wrought iron is a stunning and durable material that can add an extra touch of elegance to any property.

However, over time, this material can get damaged, which can take away from its charm. Traditionally, welding was the go-to method for repairing wrought iron, but now there are other methods available that can be just as effective.

One of these methods is using epoxy. Epoxy is a two-part adhesive that consists of resin and hardener.

When mixed together, they create a potent bond that can fill gaps, cracks, and holes in wrought iron. So, how do you go about using epoxy to repair wrought iron?

Let’s find out.

Firstly, you need to ensure that the surface of the wrought iron is clean.

Use a wire brush or sandpaper to remove any rust or old paint. Once the surface is clean, wipe it down with a cloth dampened with acetone or another solvent to remove any remaining debris.

Next, mix together the epoxy according to the manufacturer’s instructions. Apply the mixture to the area that needs to be repaired, making sure to fill in any gaps or holes.

Use a putty knife or spatula to smooth out the surface and remove any excess epoxy. Allow the epoxy to cure completely before sanding it down with fine-grit sandpaper.

This will create a smooth finish that can be painted over if desired. It’s important to keep in mind that while epoxy can be a robust adhesive, it may not be suitable for all repairs.

If the wrought iron has structural damage or is supporting heavy weight, welding may be necessary for a stronger and more secure repair. In conclusion, using epoxy to repair wrought iron can be an effective solution for minor repairs and cosmetic touch-ups.

With proper care and maintenance, your wrought iron can continue to add beauty and value to your property for years to come.

Using Mechanical Fasteners to Repair Wrought Iron

Wrought iron is a popular material for outdoor furniture, gates, and fences due to its beauty and durability.

However, even the sturdiest wrought iron can become damaged or broken over time. If you’re facing this dilemma, you’ll be glad to know that welding isn’t always the only solution.

Using mechanical fasteners can be an effective way to repair wrought iron without welding. To use mechanical fasteners, start by cleaning the area around the broken piece to ensure a tight fit.

Then, drill holes in both pieces of wrought iron that need to be joined, ensuring that they are the same size and aligned correctly. Insert bolts or screws into the drilled holes and tighten them with nuts or screws.

This method is simple, cost-effective, and doesn’t require any specialized skills or training. Plus, it can be done quickly and with minimal tools and equipment.

It’s a great option for DIY enthusiasts who want to maintain the original look of their wrought iron piece. However, using mechanical fasteners does have some limitations.

The fasteners are visible and may affect the aesthetics of the piece. Additionally, if the wrought iron is under pressure or strain, the fasteners may not be strong enough to hold it together.

Finally, using mechanical fasteners is an excellent solution for repairing wrought iron without welding. It’s a simple and affordable method that can be done by anyone with basic DIY skills.

Using Metal Bonding Agents to Repair Wrought Iron

Metal bonding agents are a simple and cost-effective solution to repairing your beloved wrought iron pieces.

Metal bonding agents are specially formulated adhesives that effectively bond metal surfaces together. They are designed to be strong, durable, and long-lasting, making them an excellent choice for repairing wrought iron.

With proper application and care, they can provide a durable and long-lasting fix that will keep your wrought iron looking its best.

To begin the process of using metal bonding agents to repair wrought iron, ensure that the area requiring repairs is clean from any rust or dirt by using a wire brush or sandpaper.

Next, follow the manufacturer’s instructions and apply the metal bonding agent. This might involve mixing two parts of the adhesive and applying it using a brush or a syringe.

After applying the metal bonding agent, allow it to cure for several hours or up to a day, depending on the specific product you are using. During this time, avoid exposing the repaired area to moisture or putting any stress on it.

Metal bonding agents can be used to repair wrought iron fences, gates, furniture, and other wrought iron objects. However, it is important to note that while they can be a great temporary solution, they may not provide the same level of strength as welding.

If you are looking for a more permanent fix, welding may be the better option.

So, don’t let a broken wrought iron piece ruin your outdoor decor.

Tips for Successful Repairs

If you’re tasked with repairing wrought iron, it can be a daunting job. However, there are several tips and tricks you can follow to ensure that your repair job is effective and long-lasting. In this article, we’ll cover five subtopics that will help you get the job done right.

Start with a Clean Surface

The first step in any repair job is to clean the area you’re going to repair. Use a wire brush or sandpaper to remove any rust or debris from the surface of the wrought iron.

This will ensure that any repair materials adhere properly and create a strong bond. A clean surface is essential for a successful repair job.

Choose the Right Materials

There are many different types of fillers, adhesives, and sealants available, so it’s important to choose the right one for your specific repair job. Consider the type of damage you’re repairing and the environment in which the wrought iron is located.

For example, if the wrought iron is outside and exposed to the elements, you may need a more durable product than if it were inside.

Follow the Manufacturer’s Instructions

When using any repair products, it’s important to follow the manufacturer’s instructions carefully. This may involve mixing the product in a specific way or allowing it to cure for a certain amount of time before painting or applying additional layers.

By following these instructions, you can ensure that your repair job is effective and long-lasting.

Use Clamps or Other Methods to Hold the Repair in Place

While waiting for the adhesive to set, use clamps or other methods to hold the repaired area in place. This will help ensure a strong and even bond. It may also be necessary to apply pressure to the repaired area using weights or other heavy objects.

Taking these steps will help ensure that your repair job is successful.

Take Steps to Prevent Future Damage

Once your repair job is complete, take steps to prevent future damage to the wrought iron. This could involve applying a protective coating or sealant to the repaired area or taking steps to prevent moisture from getting into the metal.

By taking these steps, you can ensure that your repair job lasts for years to come.

So, repairing wrought iron without welding can be challenging, but by following these simple tips and tricks, you’ll be able to get the job done right.

Remember to start with a clean surface, choose the right materials, follow the manufacturer’s instructions carefully, use clamps or other methods to hold the repair in place, and take steps to prevent future damage.

zEUUVzzZdjY” >

Conclusion

To sum up, repairing wrought iron without welding is feasible with alternative methods such as epoxy, mechanical fasteners, brazing, and metal bonding agents.

These methods are cost-effective, user-friendly and don’t require specialized skills or equipment. However, it’s crucial to choose the appropriate method for your specific repair needs to ensure a long-lasting repair that will endure the test of time.

When repairing wrought iron, starting with a clean surface is essential. Additionally, selecting the right materials for the job and following the manufacturer’s instructions carefully are vital steps.

Wrought iron is a timeless material that can add an extra touch of elegance and value to any property.