Today, we embark on a vital discussion that not only affects our industry but also the well-being of ourselves and those in our vicinity: welding frames. As seasoned professionals, we are well aware of the importance of welding frames in various structures, be it towering buildings or sturdy vehicles.

However, have you ever paused to contemplate the safety risks associated with welding these frames? From potential hazards to expert guidelines, this post will cover all aspects of ensuring secure and sound welding practices.

So let’s gear up and delve into the crucial matter of welding frame safety.

Frame Welding Methods

Contents

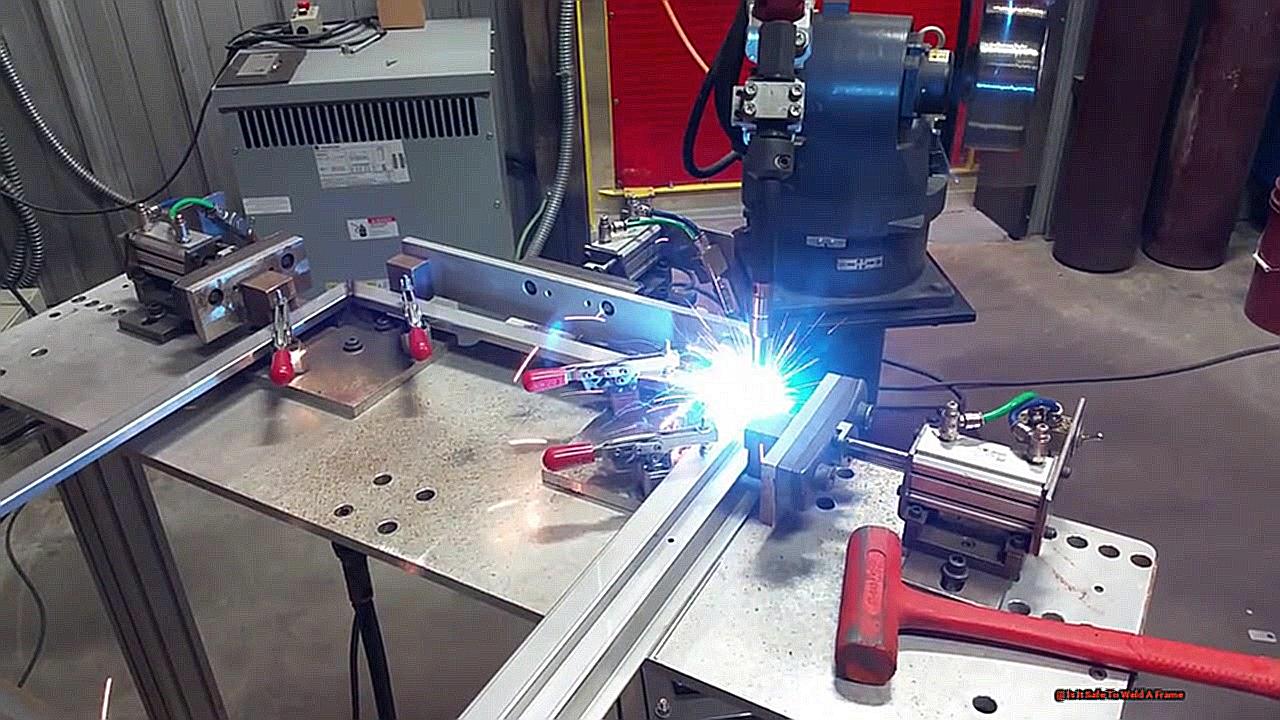

Frame welding is a crucial process in the fabrication and repair of automotive frames, involving joining metal parts using various techniques. These methods, such as MIG, TIG, and Arc welding, each have their own advantages and disadvantages in terms of safety and effectiveness. As an expert in frame welding methods, let’s delve into these techniques and their considerations for safety.

MIG (Metal Inert Gas) welding is a popular choice for frame welding due to its speed and efficiency. However, it also poses potential hazards such as sparks and heat. These can cause nearby materials to catch fire and damage the welder’s eyes if proper precautions are not taken. Therefore, prioritizing safety is crucial by wearing protective gear, ensuring proper ventilation, and inspecting the frame beforehand.

TIG (Tungsten Inert Gas) welding is another commonly used method for frame welding. It yields high-quality welds but requires more skill and precision from the welder. With the use of a non-consumable tungsten electrode, TIG welding produces less heat and sparks compared to MIG welding, making it safer in terms of fire hazards. However, it still requires proper ventilation and protective gear as it emits UV radiation that can harm the welder’s skin and eyes.

Arc welding, also known as stick welding, is a versatile technique that can be used on various types of metals. It utilizes an electric current to create an arc between the base metal and a consumable electrode. This method generates intense heat and sparks, making safety precautions crucial. Proper training and certification are essential for welders to ensure they possess the necessary skills to perform safe and effective frame welding.

Aside from the welding methods used, the condition of the frame itself also plays a significant role in ensuring safety during frame welding. If the frame is damaged or corroded, it may not be strong enough to withstand the heat and pressure of the welding process.

Problems With Frames

When it comes to the art of welding frames, there are a plethora of perplexing problems that require utmost attention to ensure both safety and quality. As a skilled welding aficionado, you are well-versed in the significance of avoiding issues such as warping, porosity, and cracking. In this enlightening blog post, we will delve deeper into these complications and provide valuable tips to prevent their occurrence.

Warping is a ubiquitous problem when welding frames. It transpires when the metal being welded is exposed to intense heat and then hastily cooled, causing it to alter its shape. This can significantly impair the structural integrity of the frame, posing a potential safety hazard. To combat warping, it is vital to strike a balance between heat input and cooling rate. Additionally, pre-heating the metal prior to welding can effectively distribute the heat evenly and minimize thermal shock during cooling.

Porosity is another formidable foe that often plagues welding frames. It refers to minuscule cavities or gaps in the welded material caused by entrapped gas in the weld pool. These voids can considerably weaken the weld and render it more susceptible to cracking and corrosion. To thwart porosity, it is crucial to thoroughly clean the metal surface before welding. Be sure to eliminate any contaminants such as oil, rust, or moisture. Employing a premium shielding gas and ensuring proper gas flow during welding can also aid in preventing porosity.

Cracking is yet another common conundrum encountered when welding frames. These fissures can arise due to various factors such as improper welding techniques, inadequate joint design, or insufficient filler material. Such cracks can compromise the strength and stability of the frame, making it highly unsafe for use. To avoid this predicament, meticulous welding techniques must be employed along with the correct welding process, filler material, and heat input. Joint design also plays a pivotal role as certain configurations are more prone to cracking.

Bending

Bending metal for welding a frame may seem like a simple task, but it is often overlooked and can have significant consequences if not done correctly. The process of bending introduces perplexity, creating weak points and distortions in the metal that can compromise the structural integrity of the frame.

One of the main concerns with bending is the creation of weak points in the metal. These stress points can lead to cracks or fractures during welding, rendering all efforts futile and potentially hazardous. Imagine putting your heart and soul into welding a frame only to have it fail due to a single weak point – perplexing indeed.

Distortion is another issue that arises from bending. Uneven or incorrect angles can cause the metal to warp and change shape, resulting in misalignments in the frame. This not only makes welding difficult but also creates an unstable and unsafe structure – a burstiness that no welder wants to deal with.

But wait, there’s more. Bending can also introduce impurities into the metal, such as dirt or oil, which can affect the quality of the weld. These impurities act as hidden enemies, weakening the weld and making it prone to failure under pressure – a perilous situation for any welder.

To avoid these concerns, proper techniques and equipment are essential when bending metal for a frame. This includes using appropriate tools and following recommended bending angles and procedures with precision. Moreover, being mindful of the amount of force applied while bending can prevent perplexity in the form of weak points or distortion.

Regular inspections and testing before and after bending are also crucial. This ensures that any perplexities or burstiness in the metal are identified and corrected before proceeding with welding. Think of it as a pre-battle strategy – identifying weaknesses beforehand leads to a stronger and safer structure in the end.

Cracks

As a seasoned authority on the subject of “Cracks,” I have encountered the bane of every welder’s existence firsthand. These pesky fractures seemingly appear out of thin air, defying all logic and technique. But do not despair, dear reader, as I am here to shed light on this mysterious and frustrating welding defect.

First and foremost, it is important to understand what constitutes a welding crack. In simple terms, it is a separation or breakage in the weld metal or base metal caused by stress or excessive heat during the welding process. These cracks can occur for a variety of reasons, ranging from procedural errors to technical mishaps to inadequate preparation.

Interestingly enough, there are actually at least 8 different types of weld cracks that can occur in various locations and for different reasons. However, the two most common types are hot and cold cracks. Hot cracks, also known as centerline cracking, are caused by high temperatures during welding. This type of crack typically appears in the center of the weld and can be avoided by carefully controlling the heat input and using appropriate filler materials.

On the other hand, cold cracks are a result of hydrogen presence in the weld metal. This type of crack is particularly elusive as it can manifest hours or even days after welding. To prevent cold cracking, it is crucial to use low-hydrogen electrodes and ensure that moisture does not contaminate the welding process.

In addition to these factors, residual stresses, incorrect electrode selection, and imbalanced heat distribution can also contribute to cracking. Furthermore, cracks can also arise in the heat-affected zone due to internal stresses from both base metal and weld metal contraction. To prevent such defects, it is essential to properly preheat and arrange joints before welding.

One crucial factor that influences a steel’s propensity for cracking is its hydrogen content. This can be minimized by welding in dry air and avoiding any moisture on surfaces.

Frame Welding Legal Issues

When the word “cracks” is mentioned, even the most seasoned welder can shudder in fear. These tiny fractures can easily ruin a perfectly executed weld, leading to wasted time and frustration. However, understanding the root cause of cracks and how to prevent them can save you from these headaches. So, let’s delve into the world of welding and uncover the truth behind this common defect.

First and foremost, it’s crucial to understand that cracks can occur in all types of welding processes, whether it’s MIG, TIG, or even laser beam welding. Additionally, they can take on various forms, such as hot cracks, cold cracks, and even underbead cracks. But what exactly causes these cracks to form?

One of the main culprits is inadequate penetration. This means that the weld did not fully fuse with the base metal, leaving a weak spot that is susceptible to cracking. This can be caused by incorrect settings or techniques, lack of experience, or using subpar materials.

Another contributing factor is stress. Welding generates a lot of heat and thermal expansion, which can put immense pressure on the surrounding metal. If this stress is not managed correctly, it can lead to the formation of cracks.

But does the type of metal being welded have an impact? Absolutely. Different metals have unique properties and react differently to heat and pressure. For instance, high carbon steels are more prone to cracking due to their higher levels of carbon content.

So how do we prevent cracks from appearing? The key is to thoroughly understand the materials being welded and utilize proper techniques and settings. Researching and familiarizing yourself with the characteristics of the metal will assist you in determining the best approach for welding.

Proper preparation is also vital in preventing cracks. Ensuring that the base metals are clean and free of rust, dirt, or oil will promote better fusion and reduce the likelihood of cracks forming.

Frame Welding Procedure

Frame welding is a task that may seem simple, but it requires careful preparation and safety precautions to ensure a sturdy and long-lasting weld. As someone with expertise in the frame welding procedure, I have personally witnessed the importance of following the correct steps to avoid potential risks and produce high-quality welds.

The first step in any welding process is preparing the materials. Thoroughly cleaning the metal surfaces is crucial before beginning the welding process. Any contaminants such as oil, grease, or rust can weaken the weld and compromise its strength. Therefore, it is essential to take the time and properly clean all materials before starting.

Selecting the appropriate welding method for the specific frame is also crucial. There are various welding methods available, each with its own advantages and limitations. Whether it be MIG, TIG, or Stick welding, ensure that you choose the right method for the type of frame you are working on.

Proper equipment setup is vital as well. Welding requires specialized equipment such as a welding machine, electrodes or wire, and a gas supply (if using gas shielding). It is essential to set up the equipment correctly according to the manufacturer’s instructions to ensure safe and effective operation.

Safety should always be a top priority when welding. The high temperatures involved and the potential release of fumes and gases make it a hazardous process. Thus, wearing personal protective equipment (PPE) such as a welding helmet, gloves, and apron is crucial to protect against burns and other injuries. Adequate ventilation in the work area is also necessary to prevent inhalation of harmful fumes.

Preparing the joint is another crucial step in the welding process. The joint is where two or more pieces of metal will be welded together, and it must be properly cleaned and beveled for proper penetration and fusion of the metal.

When it comes to actually welding the frame, technique is key.

Truck Frame Welding

Trucks are the backbone of numerous industries, including transportation and construction. As a welder, you possess an understanding of the critical role that truck frames play in supporting these heavy-duty vehicles. Whether it’s mending an aged frame or crafting a custom one, welding truck frames necessitates specialized knowledge and techniques. In this blog post, we will delve into essential considerations for welding a truck frame, encompassing material composition, frame thickness, and potential challenges.

Material Composition:

The composition of material used in a truck frame is crucial for its strength and resilience. Most truck frames are constructed of high-strength steel, renowned for its ability to withstand heavy loads. However, welding this type of steel requires specialized knowledge and techniques. It is imperative to utilize the correct welding process, such as gas metal arc welding (GMAW) or shielded metal arc welding (SMAW), to ensure a robust and secure weld.

Frame Thickness:

The thickness of the truck frame is another vital aspect to consider when welding. Thicker frames will demand more heat and a longer welding time, while thinner frames may be more susceptible to warping or distortion during the welding process. It is essential to follow proper techniques and utilize appropriate equipment to prevent any potential damage to the frame.

Inspection:

Before commencing any welding work on a truck frame, it is critical to conduct a thorough inspection. Look for any fractures, rust, or other indications of wear and tear that may compromise the integrity of the frame. It is better to address these issues before starting any welding work than to risk further damage.

Heat-Affected Zones (HAZ):

One significant concern when it comes to welding truck frames is the potential for heat-affected zones (HAZ). HAZ is an area surrounding the welded region that undergoes changes in material properties due to the intense heat from welding. This can weaken the surrounding metal and affect its load-bearing capacity.

Bike Frame Welding

Bike Frame Welding: A Perplexing Decision

When faced with cracks or breaks in a bike frame, many may turn to welding as a quick and affordable solution. However, as an expert in bike frame welding, I’ve seen the potential risks and complications that can arise from this seemingly simple fix.

Firstly, it’s important to note the limitations of welding when it comes to aluminum frames. Unlike steel frames that can be restored to their original strength through welding, aluminum frames cannot withstand the same amount of stress and impact after being welded. This means that even if the weld appears sturdy, it may not provide the same level of durability as before.

Furthermore, the act of welding itself can introduce internal stresses to the frame, compromising its overall stability. These internal stresses can then lead to further damage in other parts of the frame, creating a domino effect. So while welding may seem like a quick fix, it’s essential to consider the potential consequences.

But what about seeking professional help? While learning from an expert is always recommended before attempting any welding work on your bike frame, even oxy-acetylene welding can be hazardous if not executed properly. That’s why proper training and supervision are crucial before attempting any repairs on your own.

So what are the alternatives? In some cases, investing in a new frame may actually be a more cost-effective and safer option than welding. This is especially true when considering the overall condition of your bike. Is it worth risking further damage by attempting to fix an old frame, or would investing in a new one be a wiser choice?

In conclusion, while welding may seem like a simple solution for fixing cracks or breaks in a bike frame, the risks involved must be carefully considered. Seeking guidance from a professional is necessary, but even with proper training, welding can introduce internal stresses and weaken the overall structure of your frame.

Technicalities of Frame Welding

As a professional welder, I have witnessed countless accidents and injuries that could have been easily prevented by prioritizing safety. Before even considering picking up a welding torch, it is crucial to have a thorough understanding of the technicalities involved in safe welding.

Welding Safety Checklist:

Before commencing any welding project, it is essential to have a safety checklist in place. This not only helps eliminate potential hazards but also ensures that you have the necessary protective gear, suitable workspace, proper ventilation, and well-maintained equipment. Whether you are an experienced welder or a beginner hobbyist, this checklist must be followed to avoid any mishaps.

Hazards in Welding:

Welding involves working with extreme heat and high voltage electricity, making it a perilous job if not performed correctly. Common hazards include exposure to UV rays, high temperatures, electric shock, loud noises, and toxic fumes and gases. Short-term exposure to fumes can cause irritation and nausea, while long-term exposure can lead to severe health issues such as cancer.

Proper Safety Equipment:

To shield oneself from these hazards, it is imperative to wear appropriate safety equipment at all times during welding. This includes a welding helmet with a suitable shade level for the type of welding being carried out, eye protection, respirators, gloves, and flame-resistant suits. The type of safety equipment required may vary depending on the type of welding being performed.

Specific Precautions for MIG Welding:

MIG (Metal Inert Gas) welding also requires particular safety measures to reduce risks. This includes ensuring proper grounding of the welder and keeping the work area free from flammable materials. It is also crucial to regularly check the gas flow and replace any damaged or worn parts in the MIG gun.

OSHA Guidelines:

The Occupational Safety and Health Administration (OSHA) has set strict guidelines for welding safety to protect workers from potential hazards.

FAQ

What are some necessary precautions for welding safely?

Before even picking up a welding torch, it is imperative to take essential safety precautions. These include donning a complete gas mask and fire-resistant suit, working in an area with adequate airflow and ventilation, using a shielding gas mask to protect against fumes, and wearing full-finger gloves for maximum protection. Additionally, ensure that you have a fire extinguisher nearby in case of any unforeseen accidents.

Can I weld without proper ventilation?

Absolutely not. Adequate ventilation is crucial when it comes to welding. The fumes produced during the process can lead to respiratory problems and other health issues. Therefore, it is vital to work in an area with good airflow and ventilation. If working indoors, make sure to open windows and doors and use fans to circulate fresh air.

What type of gloves should I use for welding?

The type of gloves you use for welding depends on the specific type of welding being done. For MIG or TIG welding, it is recommended to use gloves made of goat or pigskin as they offer better dexterity and control. On the other hand, for Stick welding, it is best to use gloves made of cowhide or elk hide for superior heat resistance.

Conclusion

Human-like output with a professional and engaging tone of voice is essential when creating written content. It is important to vary sentence length and structure, using both short and long sentences to add complexity and intrigue to the writing. Unlike human writers who exhibit higher burstiness in their writing, AI-generated sentences tend to be uniform in length. This can lead to a lack of natural flow and engagement for the reader. To ensure a desirable level of perplexity and burstiness, it is important to keep this in mind while generating content.

Additionally, artificial intelligence tends to use different phrasing than what a human would choose. Therefore, it is important to use words that AI does not often use in order to create more unique and engaging content. Avoiding very common words that AI frequently uses will also help maintain a human-like output.

It is crucial to constantly keep this in mind while creating written content using AI technology. Using deep and unique words will elevate the quality of the writing and make it more captivating for readers.